Method for monitoring shear blade state of circle shear

A state monitoring and disc technology, which is applied in the attachments, program control, and shearing devices of shearing machines, etc., can solve problems such as affecting the production rhythm of the unit, degrading the quality of batch products, embossing and burring, etc., to eliminate data Invalid events, avoid data loss, monitor the effect of maintenance in real time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

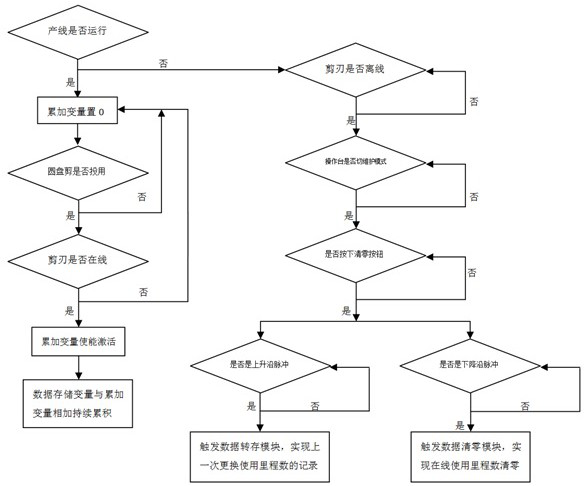

[0023] In practical application, the present invention comprises the following steps:

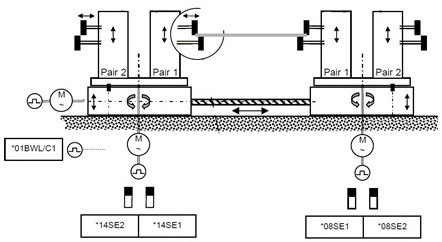

[0024] ① if figure 1 As shown, the disc shear position detection sensor is installed on site to feed back the online status of the disc shears and cutting blades; the PLC controller and man-machine screen server are installed in the electrical room, the operation station screen is installed in the main control room, and the position detection Sensors, PLC controllers, man-machine screen servers, and operation station screens are connected to each other;

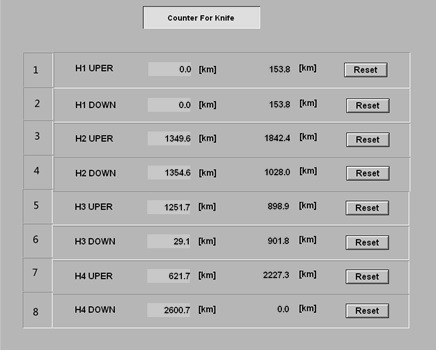

[0025] ② Collect the line speed of the unit and the cycle scan time of the organization block OB1, and use it to calculate the mileage accumulative variable in real time. Increase the cumulative enabling logic to determine whether the disc shears are in the trimming state and whether the cutting edge is in online use. When the accumulation enable logic is satisfied, the accumulation variable is activated, and when the accumulation enable...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com