Diaper type pet pants processing equipment

A processing equipment, diaper-type technology, applied in the fields of medical science, absorbent pads, underwear, etc., can solve the problems of the impact of pet pants production efficiency, the impact of people's feelings on the site environment, the need for more manual operations, etc., to improve processing efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

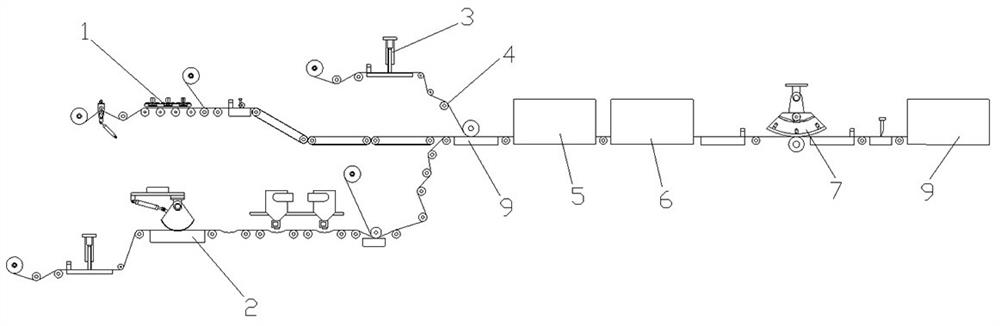

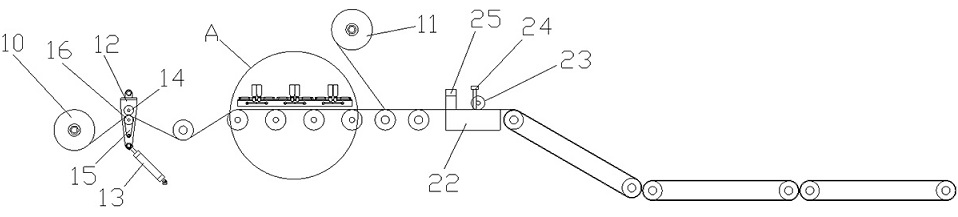

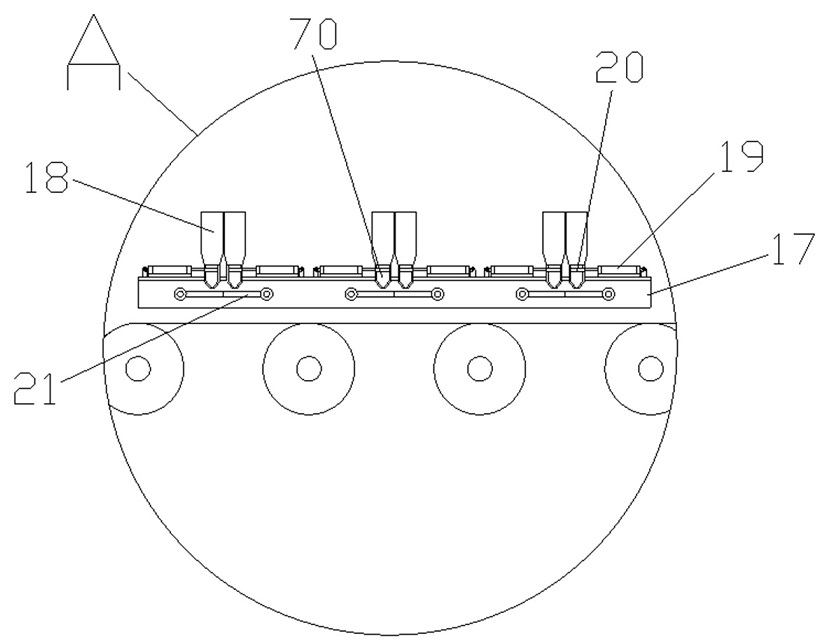

[0033] Such as figure 1 As shown in the above, a diaper-type pet trousers processing equipment includes an absorbent core processing mechanism 1, a trouser body processing mechanism 2, an inner layer non-woven fabric opening mechanism 3, a transmission mechanism 4, an elastic partition processing mechanism 5, an elastic Waist circumference processing mechanism 6, cutting mechanism 7 and packing mechanism 8, the intersection of described absorbent core body processing mechanism 1, trouser body processing mechanism 2, inner layer non-woven fabric opening mechanism 3 is provided with heat press mechanism 9, and described elastic The partition processing mechanism 5, the elastic waist processing mechanism 6, the cutting mechanism 7 and the packaging mechanism 8 are sequentially arranged behind the hot pressing mechanism 9, and the transmission mechanism 4 is arranged on the core body processing mechanism, the trouser body processing mechanism 2, the inner layer The non-woven fabri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com