Drinking mineral water filling production device and method

A production device and mineral water technology, applied in packaging, liquid bottling, bottle filling, etc., can solve the problems of decreased filling accuracy, affecting the working environment, wasting water resources, etc., to improve filling accuracy and strengthen filling accuracy , Improve the effect of water pressure stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

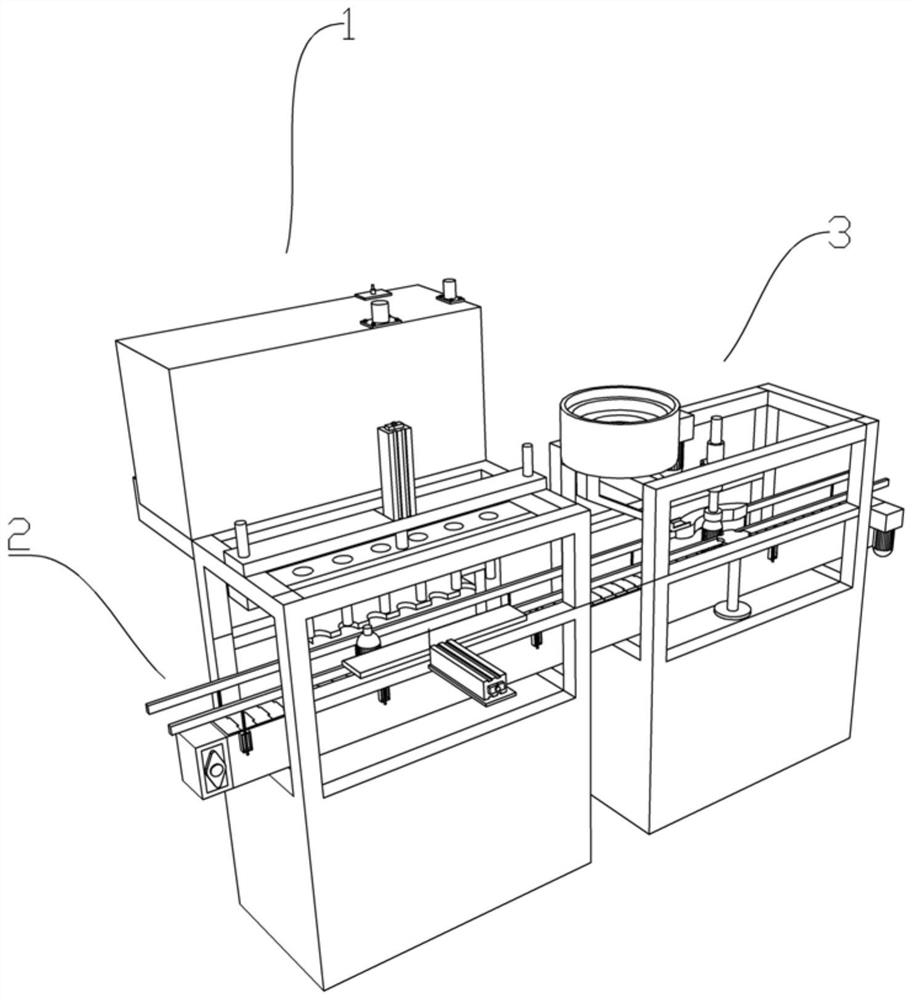

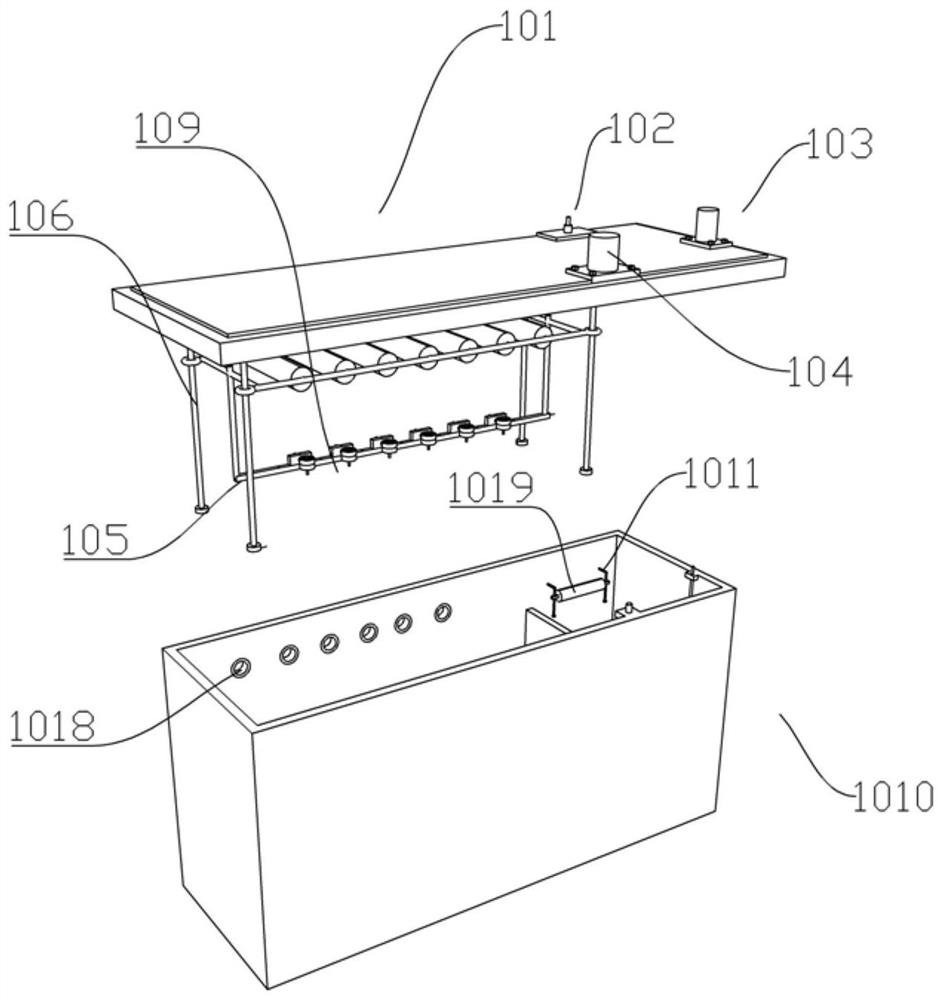

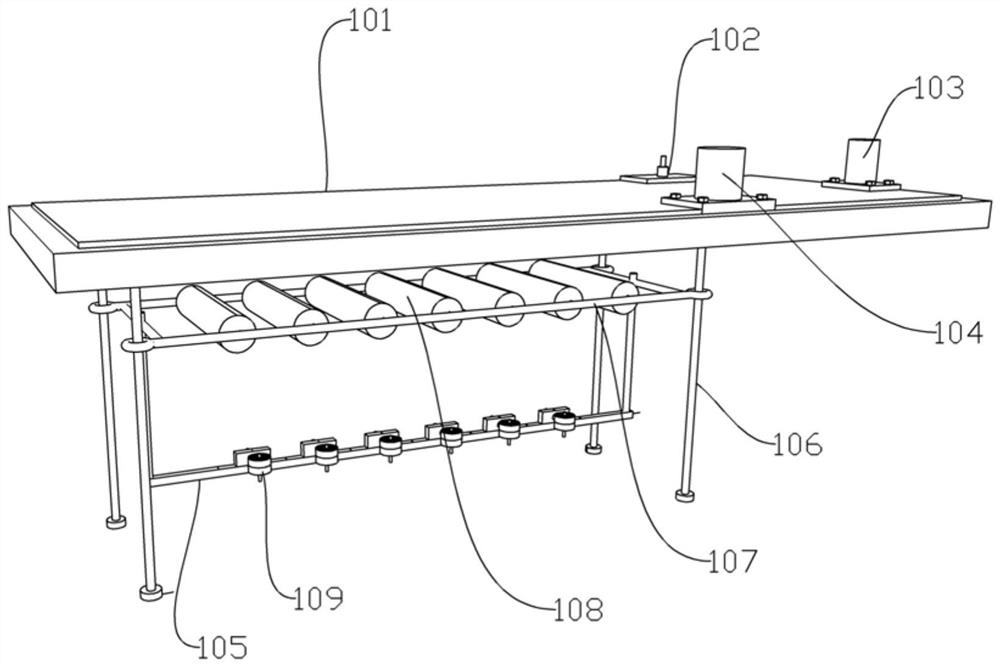

[0040] Such as Figure 1-7 As shown, a drinking mineral water filling production device includes a frame, and the frame is provided with an assembly line transmission mechanism 2 for conveying buckets, and a filling system for filling is provided above the assembly line transmission mechanism 2 1 and a capping system 3 for capping, the filling system 1 includes a water storage tank, a filling pipeline, a filling valve and a filling limit frame, and the capping system 3 includes a vibration upper cover plate and a capping device, the water storage tank includes a box body 1010 and a cover body 101, the box body 1010 is provided with a partition 1017, and the partition board 1017 divides the inner space of the water tank into a water inlet tank and a water outlet tank, and the water inlet tank A water inlet is provided at the bottom, and the water inlet is connected to a water inlet pipe. The side wall of the water outlet tank is provided with an installation port 1018, and a wa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com