Fiber decorticating device of pineapple leaf decorticating machine and intermittent pineapple leaf decorticating machine

A pineapple leaf and hemp machine technology, which is applied in fiber mechanical separation, fiber treatment, mechanical treatment, etc., can solve the problems of low extraction efficiency, high labor intensity, and failure to discharge normally.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

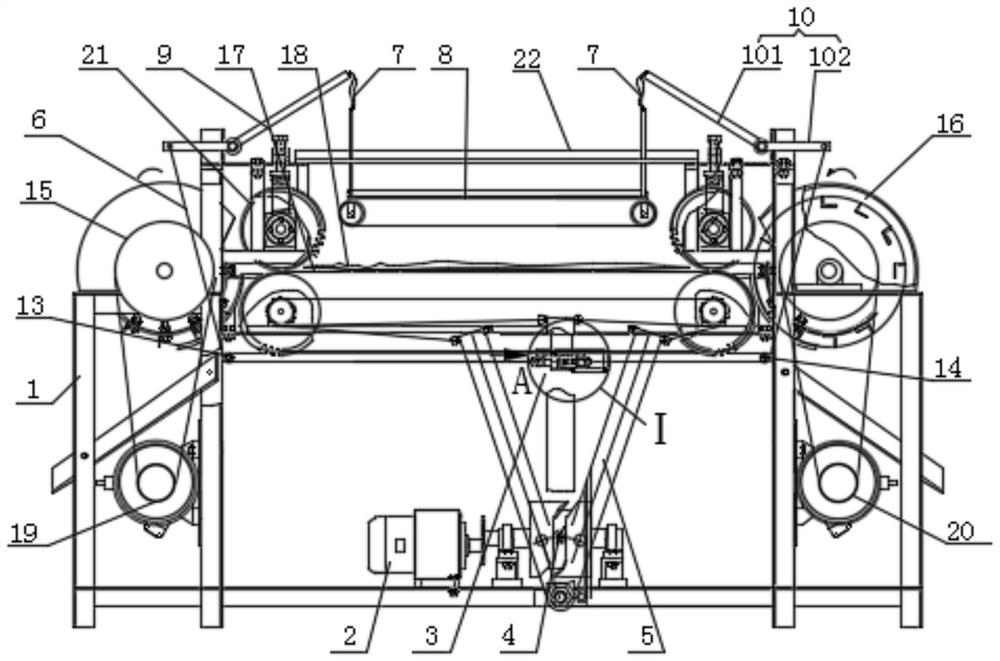

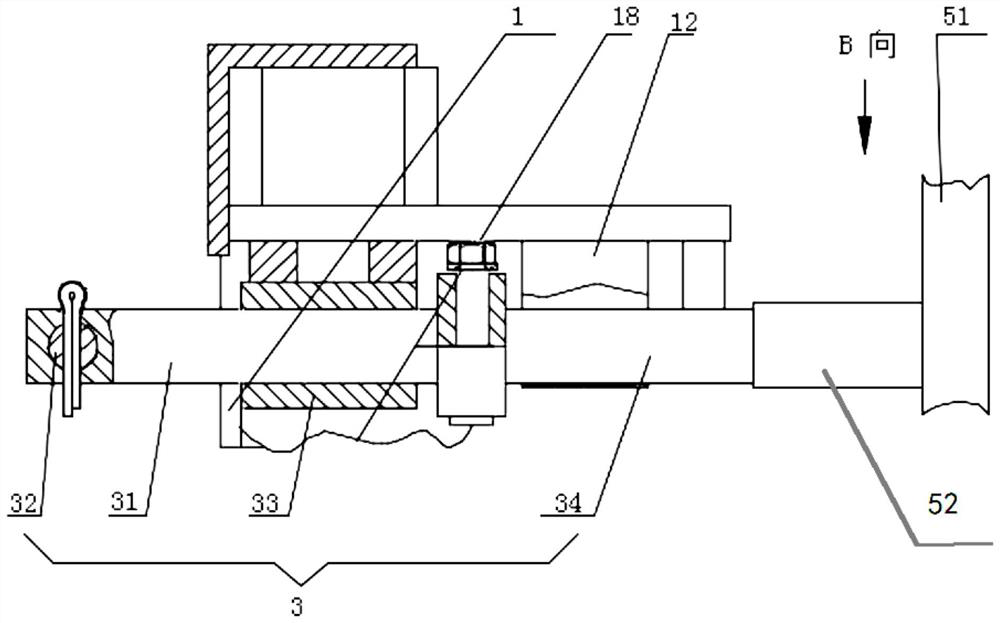

[0028] In order to enable those skilled in the art to better understand the technical solution of the present invention, the present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments. And the features in the embodiments can be combined with each other.

[0029] The present invention relates to directional indications (such as up, down, left, right, front, back...), as opposed to figure 1 As far as the horizontal paper is facing upward, it is "up", the horizontal paper is facing downward, it is "down", the horizontal paper is left, it is "left", the horizontal paper is right, it is "right", the horizontal paper is outward, it is "front", and the horizontal paper is "front". The inside of the paper is "back", if the specific posture changes, the directional indication will also change accordingly.

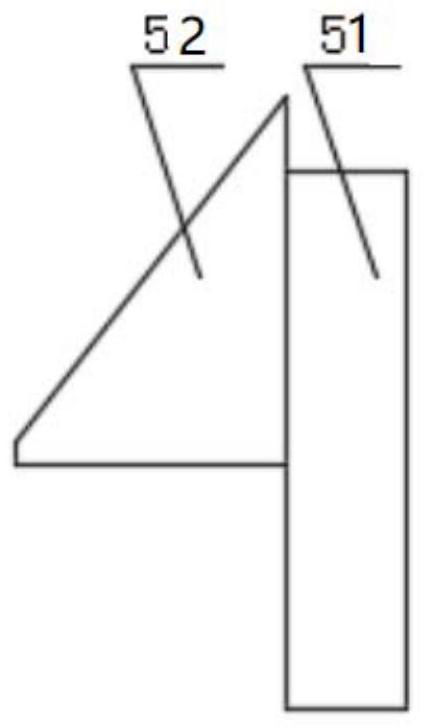

[0030] combine figure 1 As shown, the embodiment of the present invention provides a fiber stripping device...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com