Automatic down filling processing equipment for down jackets

A processing equipment and clothing technology, which is applied in the field of down garment production, can solve the problems of manpower consumption, exposure of a single down filling tube, and low work efficiency, and achieve the effects of reducing manpower, good automation effect, and improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0042] In order to further explain the technical solutions of the present invention, specific examples are given below to illustrate in detail.

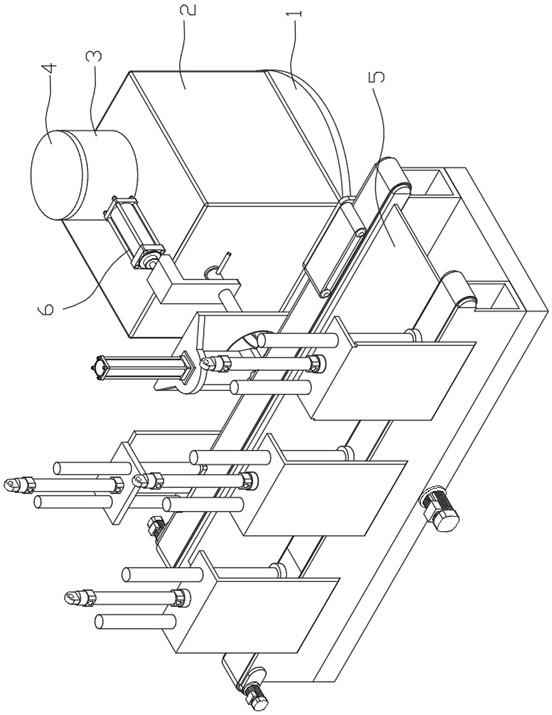

[0043] see figure 1 , the present invention provides an automatic down filling processing equipment for down garments, comprising a chassis 1, the top of the chassis 1 is connected to a down filling equipment main body 2, an introduction bucket 3 is installed on the top of the down filling equipment main body 2, and a top cover 4 is arranged on the top of the introduction bucket 3, Open the top cover 4 and inject down into the inside of the introduction bucket 3, which is collected and extracted from the inside of the main body 2 of the down filling equipment. The automatic auxiliary device 5 that can realize automatic down filling.

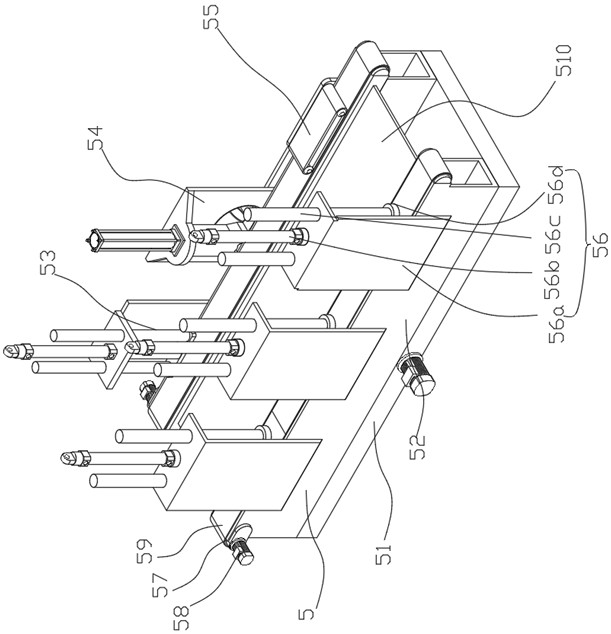

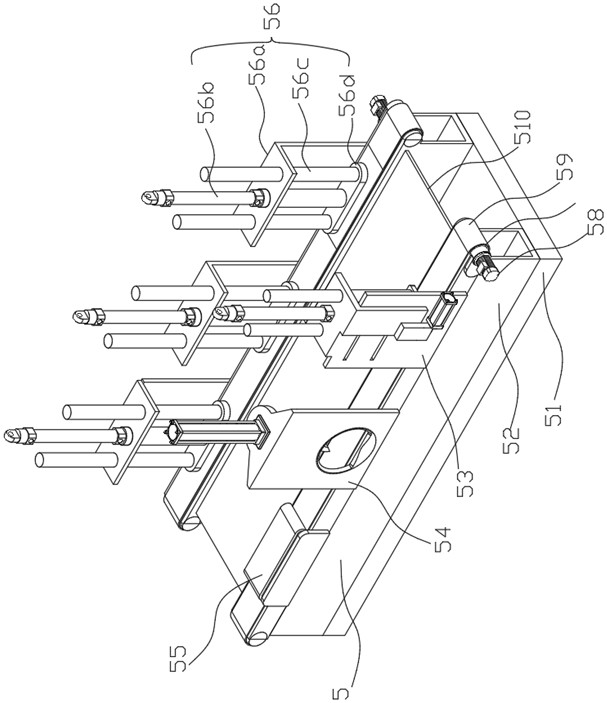

[0044] see Figure 2-3 , the present invention provides an automatic down garment filling processing equipment, the automatic auxiliary device 5 includes a pretreatment part for opening the cloth stri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com