Electric bundle for vehicle and vehicle carried said electric bundle

A wire harness, vehicle technology, applied to vehicle components, circuits, electrical components, etc., can solve the problem of not being able to take in wire harnesses

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

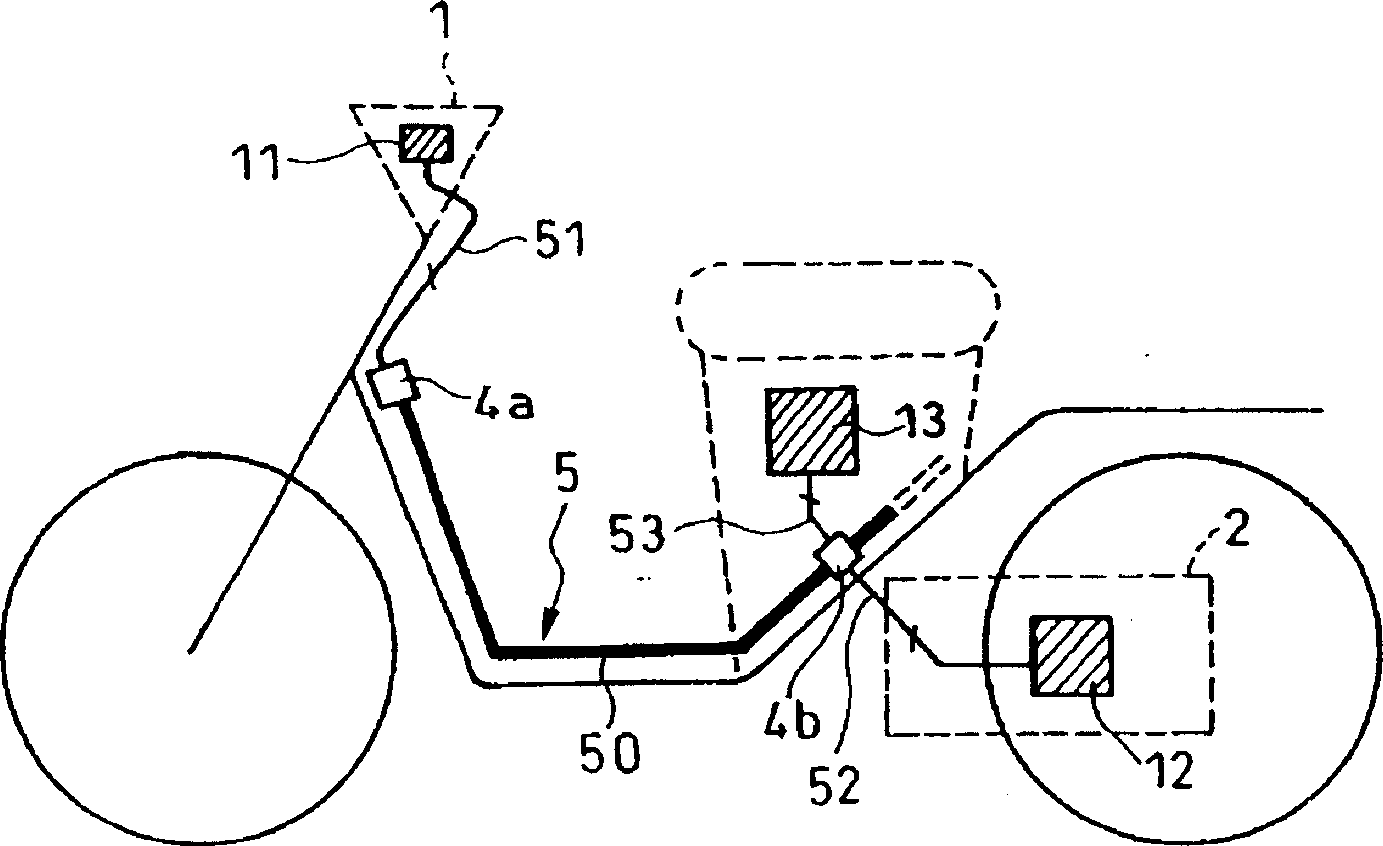

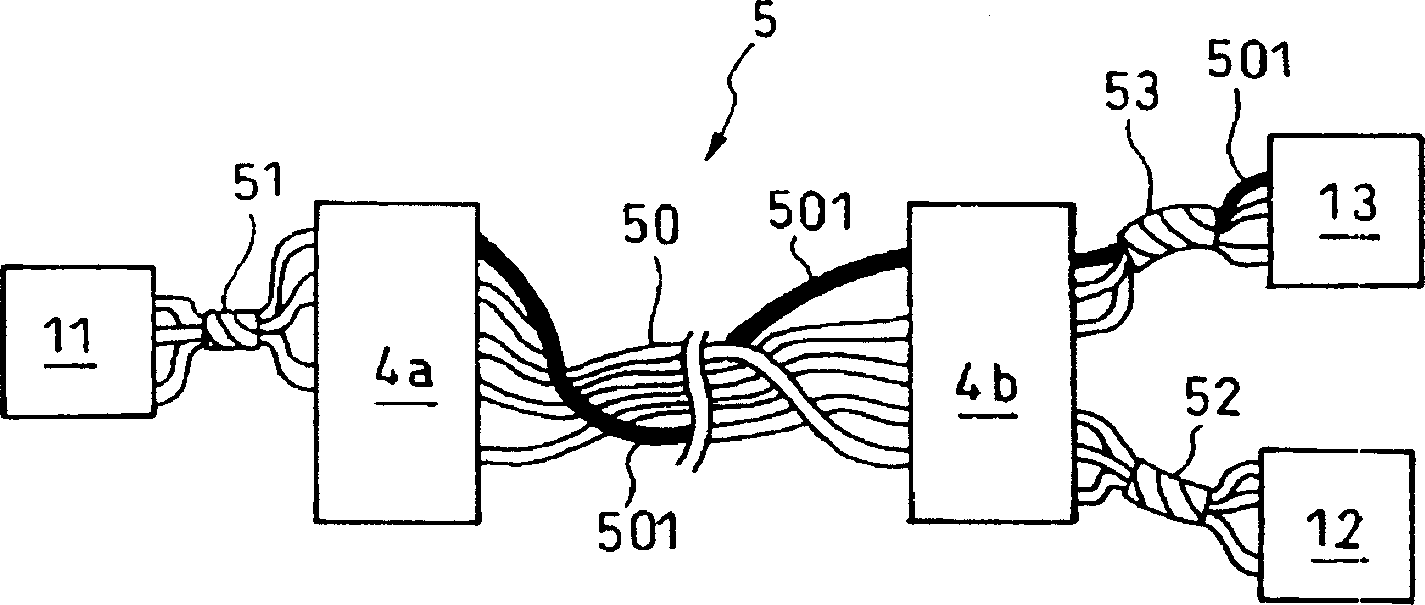

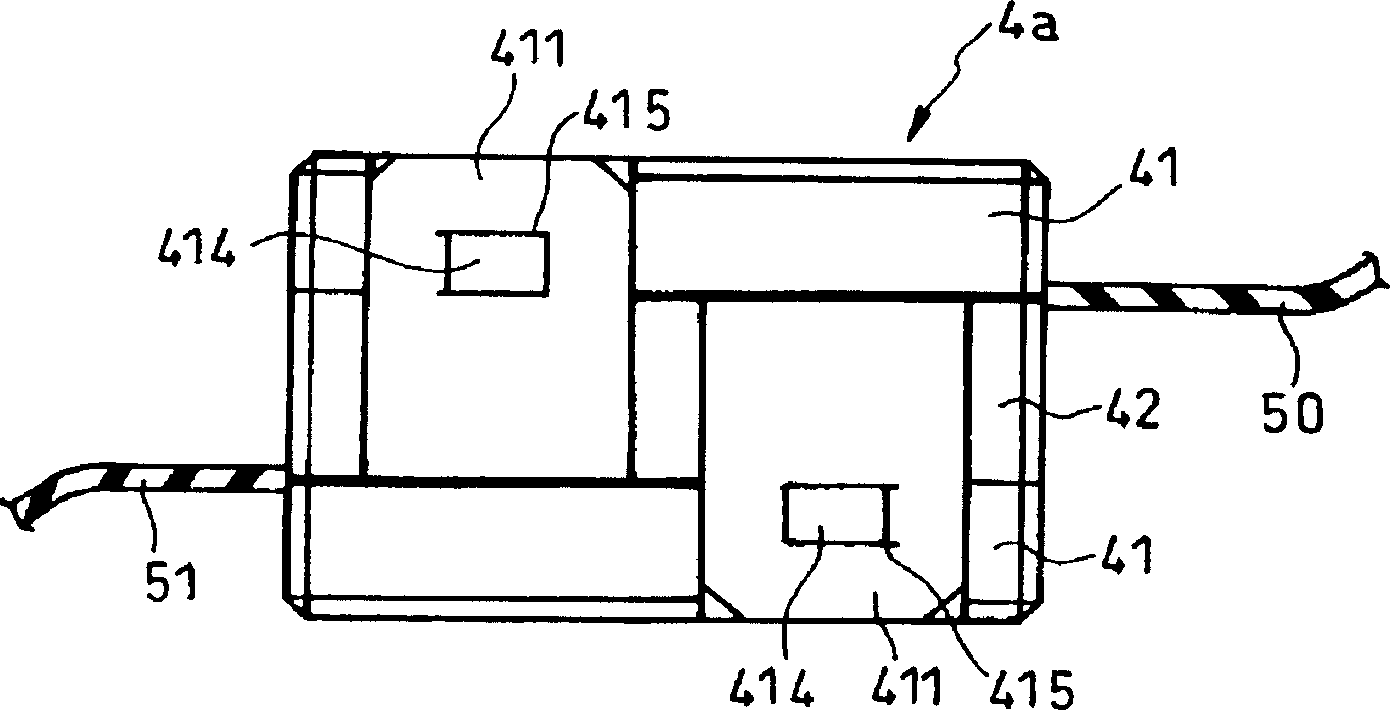

[0024] The present invention will be described in detail below with reference to the accompanying drawings. figure 1 It is a side view showing the configuration of a motorcycle using a vehicle harness according to the present invention, figure 2 is a diagram showing the configuration of the harness.

[0025] On a two-wheeled vehicle, the instrument cover 1 installed on the upper part of the steering handle is equipped with an input and output electrical device terminal 11 such as a meter or various operating switches, an engine system electrical device terminal 12 installed in the shaking device 2, and an electrical device terminal 12 installed in the steering handle. A plurality of electric terminals such as control system electric device terminal 13 such as an ECU (Engine Control Unit) in the center of the vehicle are arranged away from each other.

[0026] The wire harness 5 that interconnects the terminals of the electrical devices is constituted by electrically and mech...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com