Maintenance box for optical fiber composite power cable

A power cable and optical fiber composite technology, applied in the field of power cables, can solve the problems of narrow sewer space, inconvenient access to tools, inconvenient toolbox deployment, etc., and achieve the effect of saving space.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

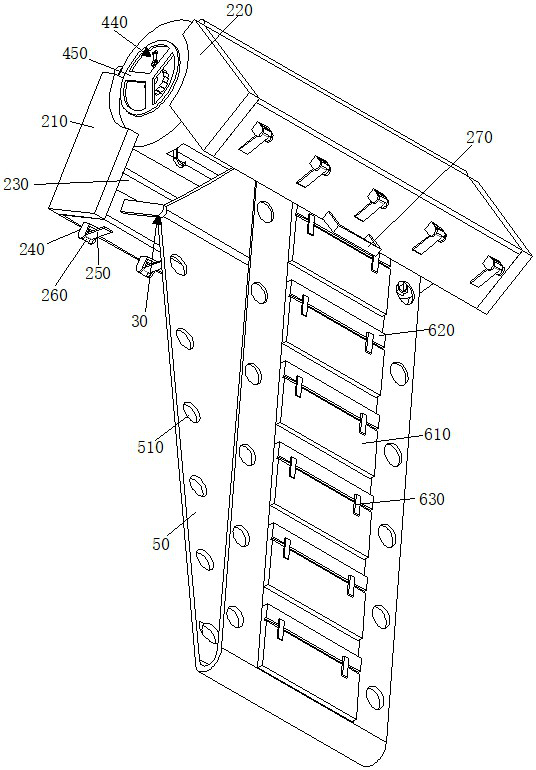

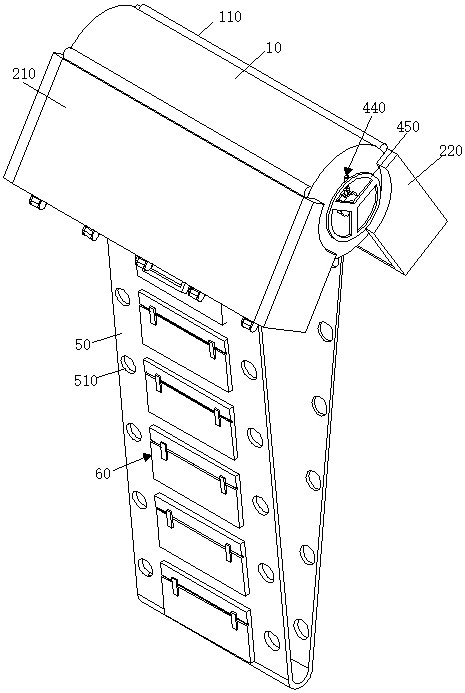

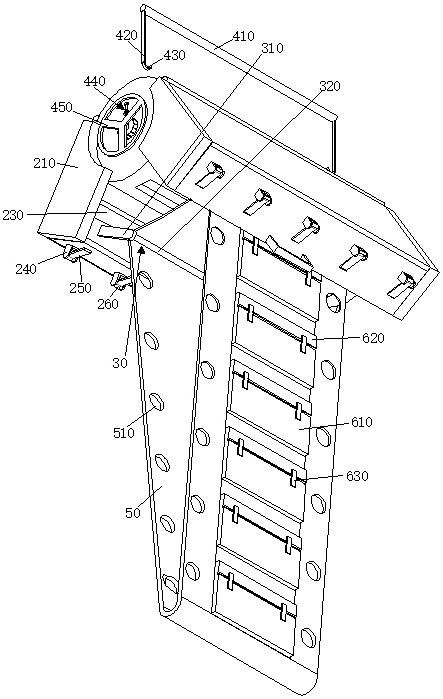

[0038] refer to Figure 1-7 , a maintenance box for optical fiber composite power cables, including a reel 10 with an opening:

[0039] The door opening and closing part 20 is movably connected to the outer wall of the winding drum 10;

[0040] The rolling auxiliary assembly 30 is arranged inside the opening and closing part 20 of the opposite door;

[0041] The winding mechanism 40 is installed on the winding drum 10;

[0042] The rolling belt 50 cooperates with the rolling auxiliary assembly 30 and is detachably connected with the winding end of the winding mechanism 40;

[0043] The tool holding part 60 is installed on the outer wall of the rolling belt 50 and is used for storing maintenance tools.

[0044] refer to Figure 6 and Figure 7 , also includes a limit protrusion 110 installed on the outer wall of the reel 10, and when the door opening and closing part 20 is unfolded, its outer wall abuts against the limit protrusion 110, and the first box body 210 and the s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com