A kind of cementing and plugging fluid and preparation method thereof

A technology for plugging fluid and cementing, which is applied in the field of cementing and plugging fluid, can solve the problems of low shear force, reduced use effect, cement precipitation and aggregation, etc. blocking effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

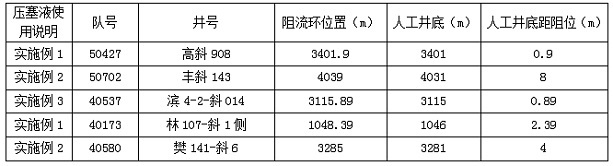

Embodiment 1

[0024] Embodiment 1: A cementing and plugging fluid, including the following raw materials: clear water; KCM004; KCM026A; KCM003.

[0025] The raw materials of the plugging liquid are proportioned by weight: clear water: 100 parts; KCM004: 1.5 parts; KCM026A: 1 part; KCM003: 0.2 parts.

[0026] In this embodiment, KCM004 is a cement suspending agent for oil wells; KCM026A is a cement retarder for oil wells; KCM003 is a cement defoamer for oil wells.

[0027] In this embodiment, KCM004, KCM026A and KCM003 are all products that are normally sold in the market and can be directly purchased in the market.

[0028] The invention also discloses a preparation method of the cementing and plugging fluid, and the preparation method comprises the following steps:

[0029] X1. Pump in clean water on the cement truck: 100 parts, turn on the mixer and keep its speed at 40 rpm for mixing.

[0030] X2. Weigh KCM004: 1.5 parts, and add it to the clear water, and then continue to stir for 10 ...

Embodiment 2

[0034] Example 2: A cementing and plugging fluid, the proportions by weight include the following raw materials: clear water: 110 parts; KCM004: 2 parts; KCM026A: 1.5 parts; KCM003: 0.3 parts.

[0035] A preparation method of cementing and plugging fluid, the preparation method comprises the following steps:

[0036] X1. Pump in clean water on the cement truck: 110 parts, turn on the mixer to keep its speed at 60 rpm;

[0037] X2. Weigh KCM004: 2 parts, add it to the clear water, and then continue to stir for 15 minutes;

[0038] X3. Weigh KCM026A: 1.5 part; KCM003: 0.3 part in turn and add them to the cement truck, and continue to stir for 15 minutes. After the stirring is completed, the cementing and plugging fluid is prepared.

[0039] The viscosity and shear force of the cementing and plugging fluid prepared in the above Example 2 were tested. After testing, the cementing and plugging fluid in Example 2 had the following indicators: plastic viscosity PV: 10 mPa·s; dynamic...

Embodiment 3

[0041] Embodiment 3: A cementing and plugging fluid, which includes the following raw materials in proportion by weight: clear water: 120 parts; KCM004: 3 parts; KCM026A: 2 parts; KCM003: 0.5 parts.

[0042] A preparation method of cementing and plugging fluid, the preparation method comprises the following steps:

[0043] X1. Pump 120 parts of clean water on the cement truck, turn on the mixer and keep its speed at 80 rpm;

[0044] X2. Weigh KCM004: 3 parts, and add it to the clear water, and then continue to stir for 20 minutes;

[0045] X3. Weigh KCM026A: 2 parts; KCM003: 0.5 parts in turn and add them to the cement truck, and continue to stir for 20 minutes. After the stirring is completed, the cementing and plugging fluid is prepared.

[0046] The viscosity and shear force of the cementing and plugging fluid prepared in the above Example 3 were tested. After testing, the cementing and plugging fluid in Example 3 had the following indicators: plastic viscosity PV: 16 mPa·...

PUM

| Property | Measurement | Unit |

|---|---|---|

| service temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com