Steel structure bridge truss with buffering characteristic

A steel structure and bridge technology, applied in bridges, bridge construction, bridge parts, etc., can solve problems such as large shear force and limited durability of connectors, achieve good support stability, reduce installation costs, and reduce quantities Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

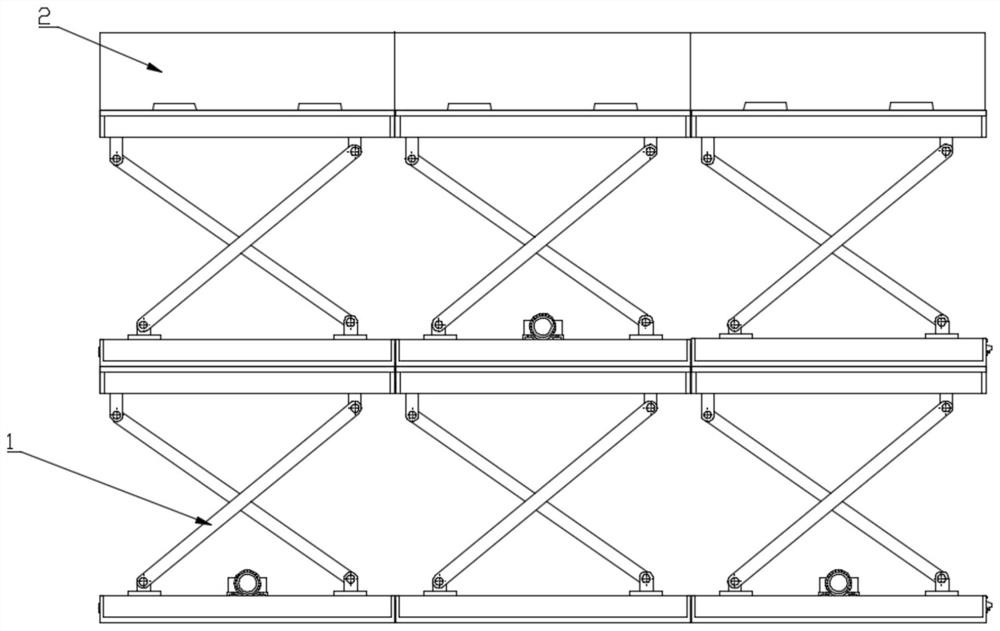

[0029] refer to figure 1 , in this embodiment, a steel structure bridge truss with cushioning properties is proposed, and the steel structure bridge truss with buffering properties includes: a splicing unit 1 and a supporting top plate 2; the supporting top plate 2 is installed on the splicing unit 1, The supporting top plate 2 is adapted to the piece to be supported.

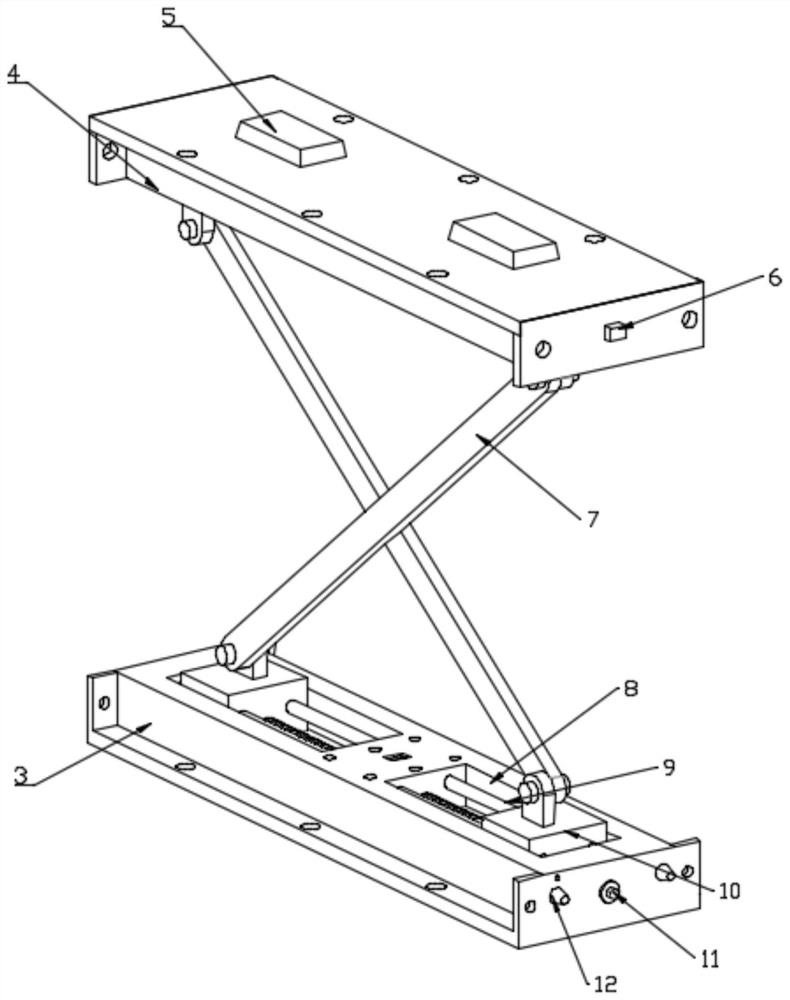

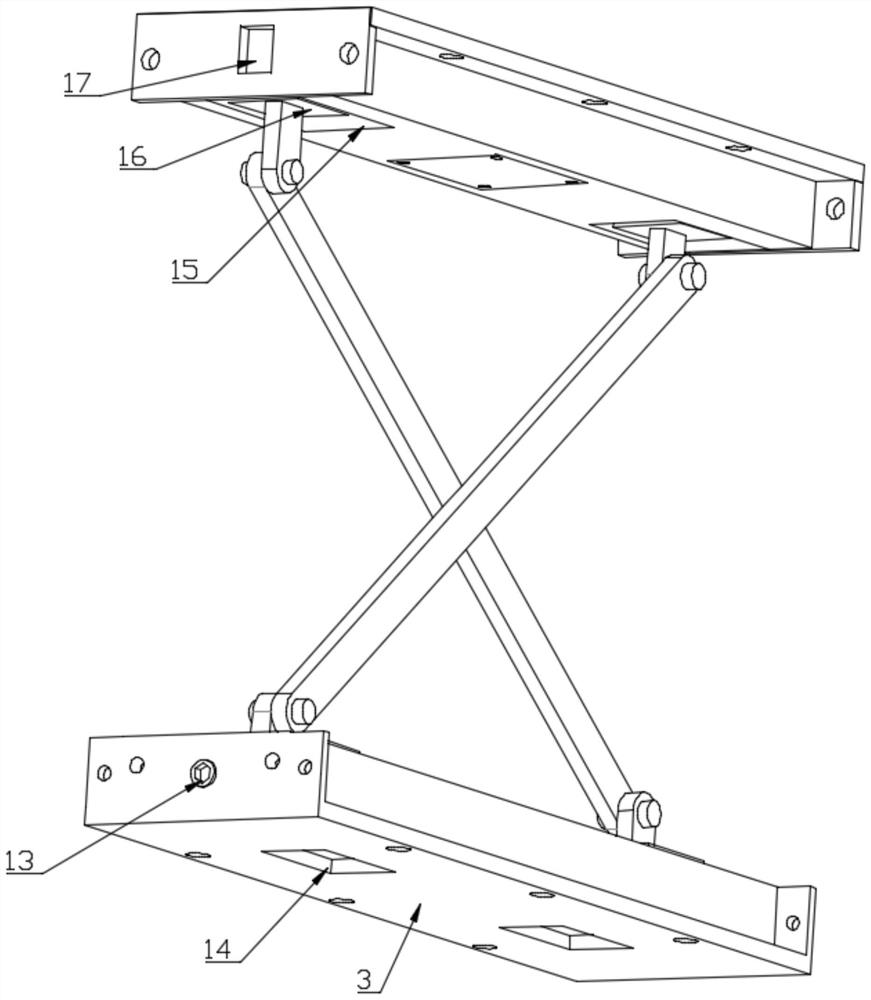

[0030] There are several splicing units 1, and each splicing unit 1 is spliced to form a bracket structure. The splicing unit 1 includes a bracket unit and a top unit, and the top unit is fixed on the top of the bracket unit to form a bracket structure. refer to Figure 2 ~ Figure 4 , the bracket unit and the top unit both include a lower plate 3 and an upper plate 4, and the lower plate 3 and the upper plate 4 are arranged opposite to each other up and down. The upper surface of the lower plate 3 is oppositely provided with two lower sliding grooves 8, and the inner sliding portion of the lower sliding gro...

Embodiment 2

[0037] One end of the upper plate 4 of the top unit is provided with a positioning sliding groove 17, and the other end of the upper plate 4 is fixedly provided with a positioning sliding block 6. When the top unit is spliced, the positioning sliding block 6 slides and nests inside the positioning sliding groove 17. Thereby, the connection and buffering of the top unit are facilitated, and the connection buffering capacity is increased.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com