Organic working medium distributed energy supply system evaporator liquid level balance control system and method

A technology of control system and liquid level balance, which is applied in the direction of machines/engines, mechanical equipment, steam engine devices, etc., and can solve the problems of reduced pump efficiency, unreasonable economy, and inability of liquid to enter the evaporator

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

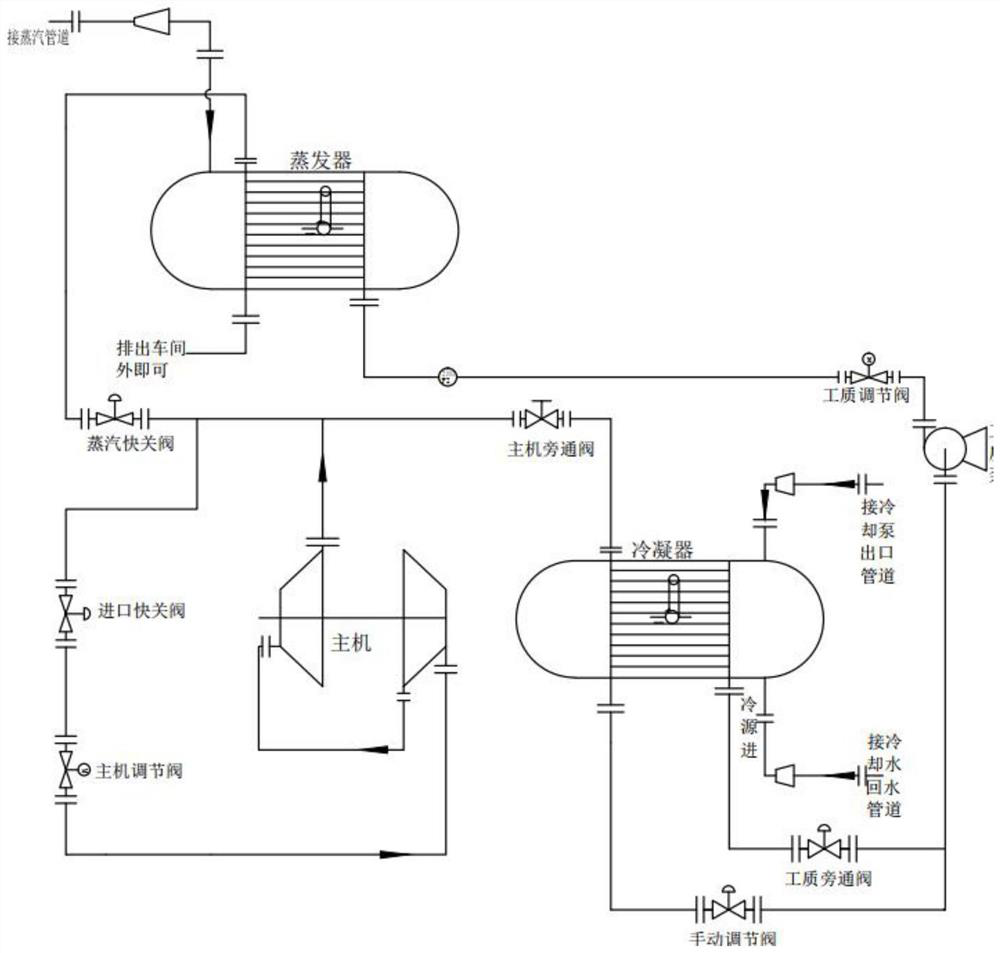

[0019] figure 1 It is an evaporator liquid level balance control system of an organic working medium distributed energy supply system.

[0020] The waste heat steam enters the evaporator, and the organic working medium in it absorbs the waste heat and turns into steam, and the steam is passed into the expander, which drives the expander to work, drives the generator to rotate, and generates electricity. The organic working medium after work enters the condenser to cool down, and the organic working medium cooled to liquid enters the evaporator for the next cycle through the action of the working medium pump. As a power generation device, it is necessary to ensure that the speed of the main engine is maintained in a very small area to ensure the quality of power. The overall system is most stable when the evaporator and condenser are in thermal equilibrium. Among them, the steam quick-closing valve and the inlet quick-closing valve are used to protect the main engine system f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com