Sealing device for oil film bearing of roller shaft of rolling mill

A technology of oil film bearing and sealing device, which is applied in the direction of engine sealing, mechanical equipment, engine components, etc., and can solve problems such as poor sealing effect, static seal failure, cumbersome installation and replacement work, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

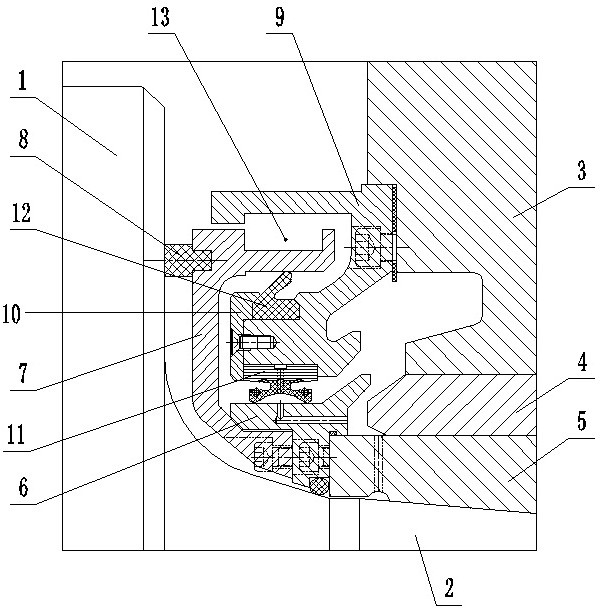

[0032] figure 1 It is a partial cross-sectional schematic diagram of an oil film bearing sealing device in the prior art. In the figure: 1 is a roll, 2 is a roll shaft, 3 is a bearing seat, 4 is a bush, 5 is a taper sleeve, and 6 is an extension ring of the taper sleeve , 7 is a labyrinth ring, 8 is a static sealing ring, 9 is a sealing cover, 10 is a gland, 11 is a cloth oil seal, 12 is a full glue water seal, and 13 is a sump.

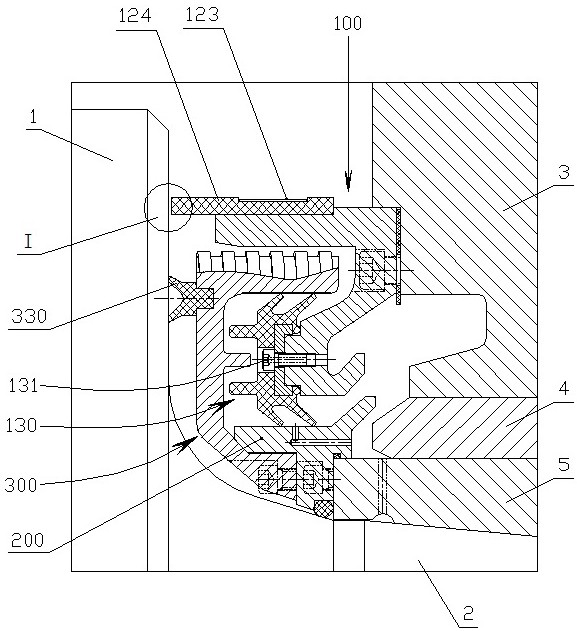

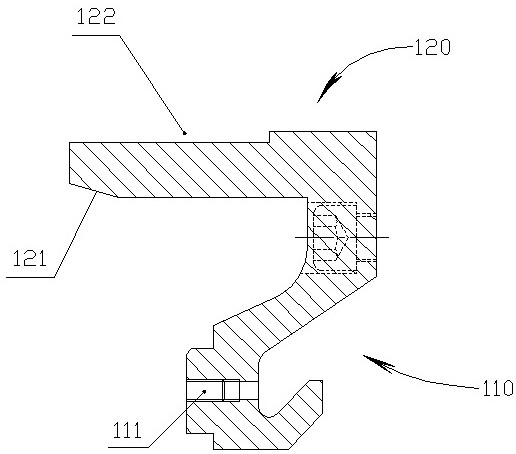

[0033] see you again figure 2 - Figure 5 , the present invention is used for the sealing device of roller shaft oil film bearing of rolling mill, comprises the sealing cover 100 that is fixed on the bearing seat, the taper sleeve extension ring 200 that is fixed on the taper sleeve and the labyrinth that is fixed on the taper sleeve extension ring Ring 300, the sealing cover has a sealing ring 110 on the inside and a water blocking ring 120 on the outside, and the labyrinth ring includes a water sealing ring 310 opposite to the end face of the ro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com