Electric power data monitoring equipment mounting rack

A technology for monitoring equipment and power data, which is applied to mechanical equipment, machine platforms/brackets, supporting machines, etc., can solve the problems of poor adaptability of installation frames, difficulty in adjusting angles and directions, etc., and achieve high adaptability and improved adaptability Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

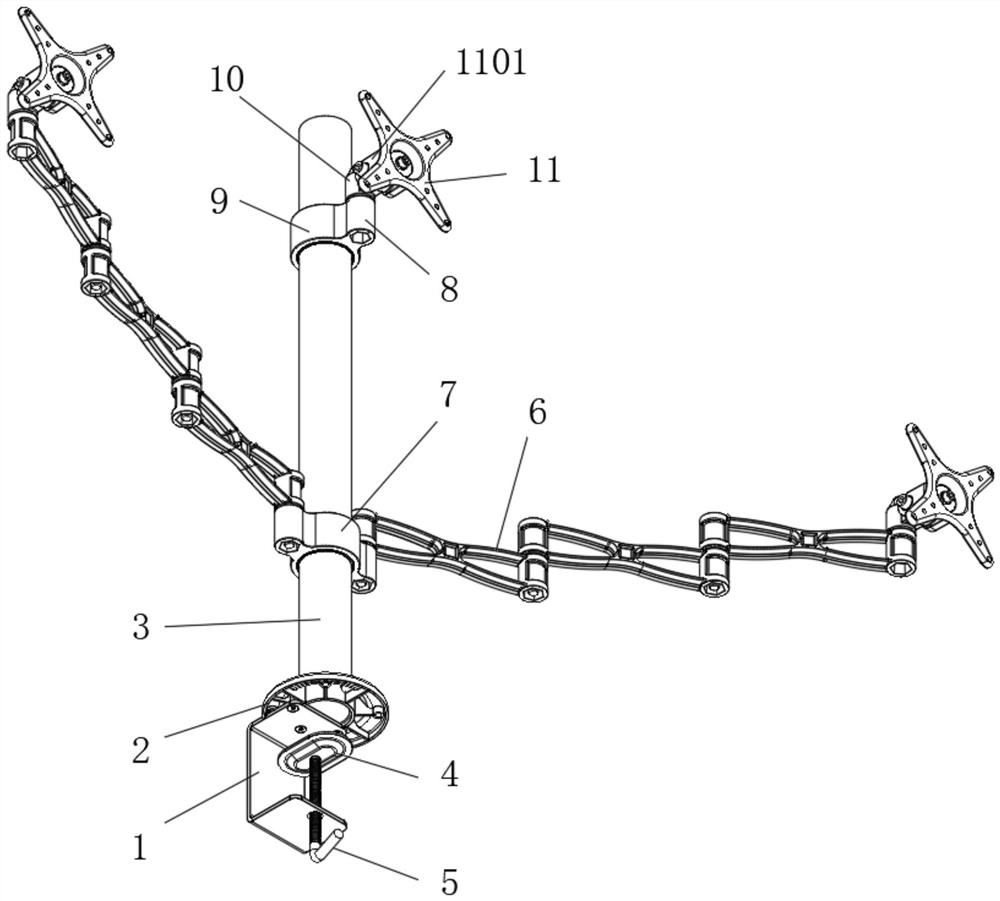

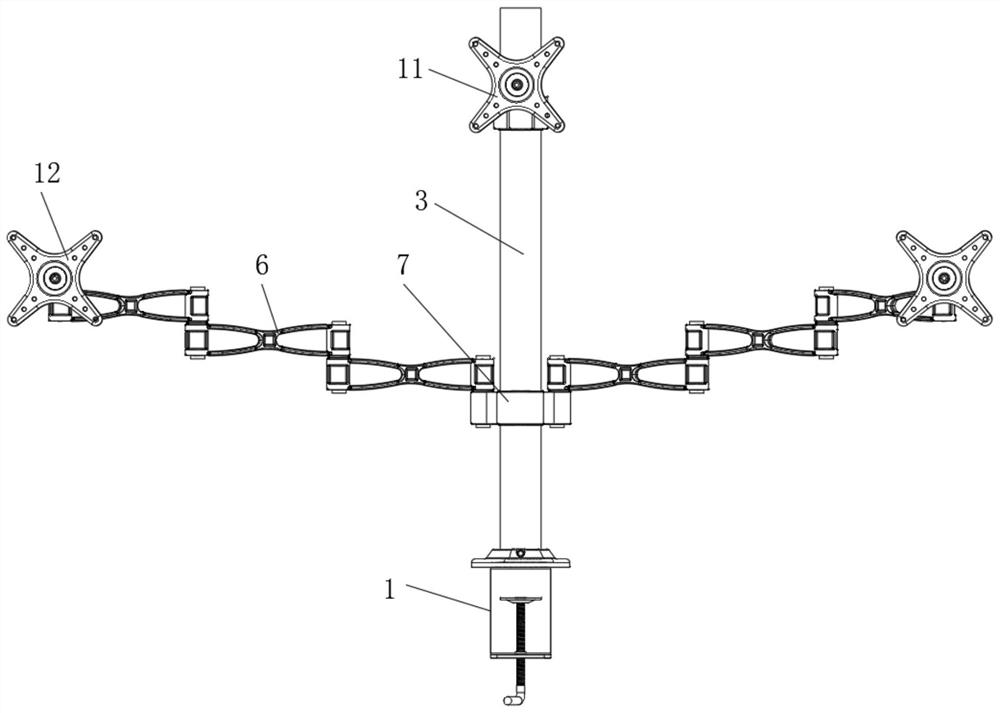

[0032] This embodiment provides a specific structure of a power data monitoring equipment installation frame, such as figure 1 As shown, the spindle rod 3 is included, the bottom of the spindle rod 3 is provided with a mounting plate 2, and the bottom of the mounting plate 2 is provided with a support member 1, and the spindle rod 3 is respectively sleeved with an upper sliding sleeve 9 and a The lower sleeve 7, the upper sleeve 9 and the lower sleeve 7 can slide up and down on the main shaft rod 3;

[0033] The front end of the upper sliding sleeve 9 is movably equipped with a first equipment mount 11, and the both sides of the lower sleeve 7 are provided with lateral struts 6, and the free ends of the lateral struts 6 are equipped with a second equipment mount 11, the first equipment The mounting base 11 and the second device mounting base 11 can rotate in the horizontal direction.

[0034] By adopting the above technical solutions:

[0035] When the device is in use, firs...

Embodiment 2

[0038] This embodiment provides a specific structure of a power data monitoring equipment installation frame, such as Figure 1-6 As shown, the spindle rod 3 is included, the bottom of the spindle rod 3 is provided with a mounting plate 2, and the bottom of the mounting plate 2 is provided with a support member 1, and the spindle rod 3 is respectively sleeved with an upper sliding sleeve 9 and a The lower sleeve 7, the upper sleeve 9 and the lower sleeve 7 can slide up and down on the main shaft rod 3;

[0039] The front end of the upper sliding sleeve 9 is movably equipped with a first equipment mount 11, and the both sides of the lower sleeve 7 are provided with lateral struts 6, and the free ends of the lateral struts 6 are equipped with a second equipment mount 11, the first equipment The mounting base 11 and the second device mounting base 11 can rotate in the horizontal direction.

[0040] The front end of the upper sliding sleeve 9 and both sides of the lower sleeve 7 ...

Embodiment 3

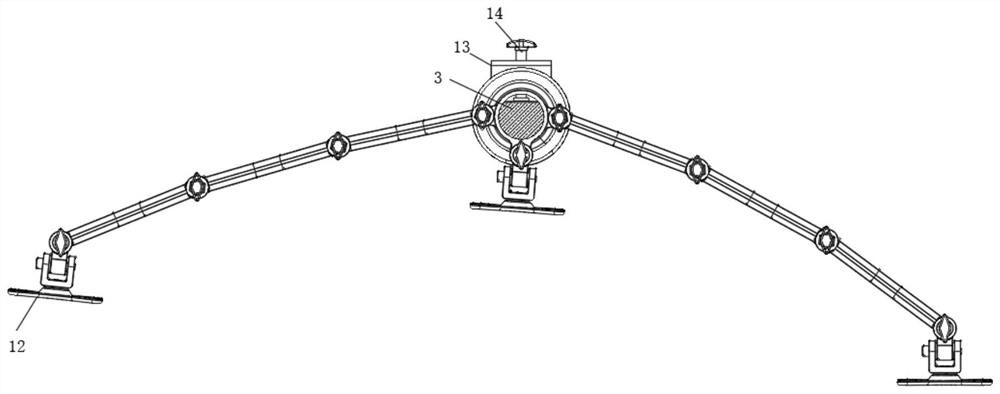

[0046] This embodiment provides a specific structure of a power data monitoring equipment installation frame, such as Figure 1-6 As shown, the spindle rod 3 is included, the bottom of the spindle rod 3 is provided with a mounting plate 2, and the bottom of the mounting plate 2 is provided with a support member 1, and the spindle rod 3 is respectively sleeved with an upper sliding sleeve 9 and a The lower sleeve 7, the upper sleeve 9 and the lower sleeve 7 can slide up and down on the main shaft rod 3;

[0047] The front end of the upper sliding sleeve 9 is movably equipped with a first equipment mount 11, and the both sides of the lower sleeve 7 are provided with lateral struts 6, and the free ends of the lateral struts 6 are equipped with a second equipment mount 11, the first equipment The mounting base 11 and the second device mounting base 11 can rotate in the horizontal direction.

[0048] The front end of the upper sliding sleeve 9 and both sides of the lower sleeve 7 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com