Rigidity measuring method and system for air spring bag skin and storage medium

An air spring and measurement method technology, which is applied in the field of vehicle engineering, can solve the problems of complicated operation and many steps in the method of pure bladder stiffness, and achieves the effect of simplifying the step process and simple and rapid measurement.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

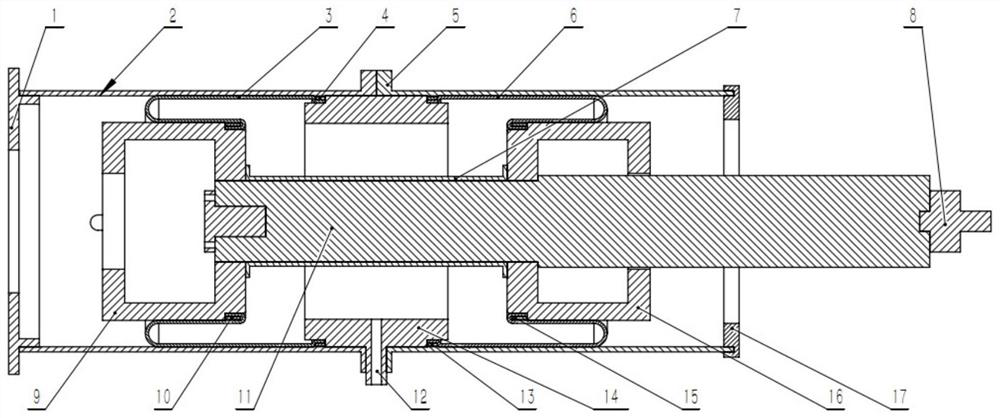

Image

Examples

Embodiment Construction

[0028] It should be understood that the specific embodiments described herein are only used to explain the present invention, but not to limit the present invention.

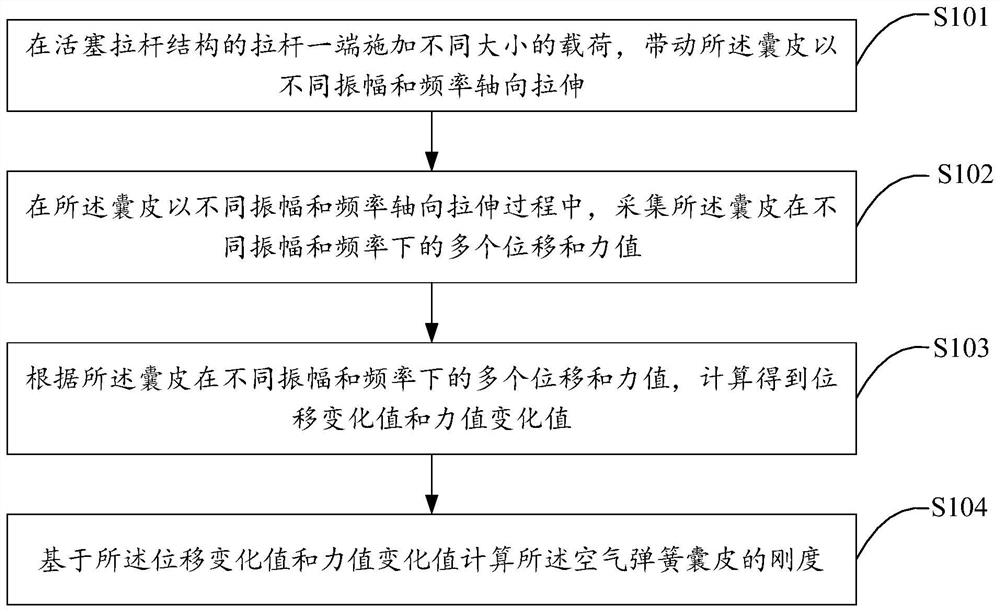

[0029] The main solution of the embodiment of the present invention is: applying loads of different sizes on one end of the rod of the piston rod structure to drive the capsule to stretch axially with different amplitudes and frequencies; During the stretching process, collect multiple displacement and force values of the capsule under different amplitudes and frequencies; according to the multiple displacement and force values of the capsule under different amplitudes and frequencies, calculate the displacement change value and force value change value; the stiffness of the air spring bladder is calculated based on the displacement change value and the force value change value. Therefore, through the above solution, the stiffness of the air spring capsule can be calculated only by applying a load at one end...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com