Equipment for uniformly scraping oil on surface of cable

A technology with uniform surface and cables, which is applied in the direction of cable/conductor manufacturing, conductor/cable insulation, and devices for coating liquid on the surface, etc. It can solve problems such as affecting use and incomplete oil scraping

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

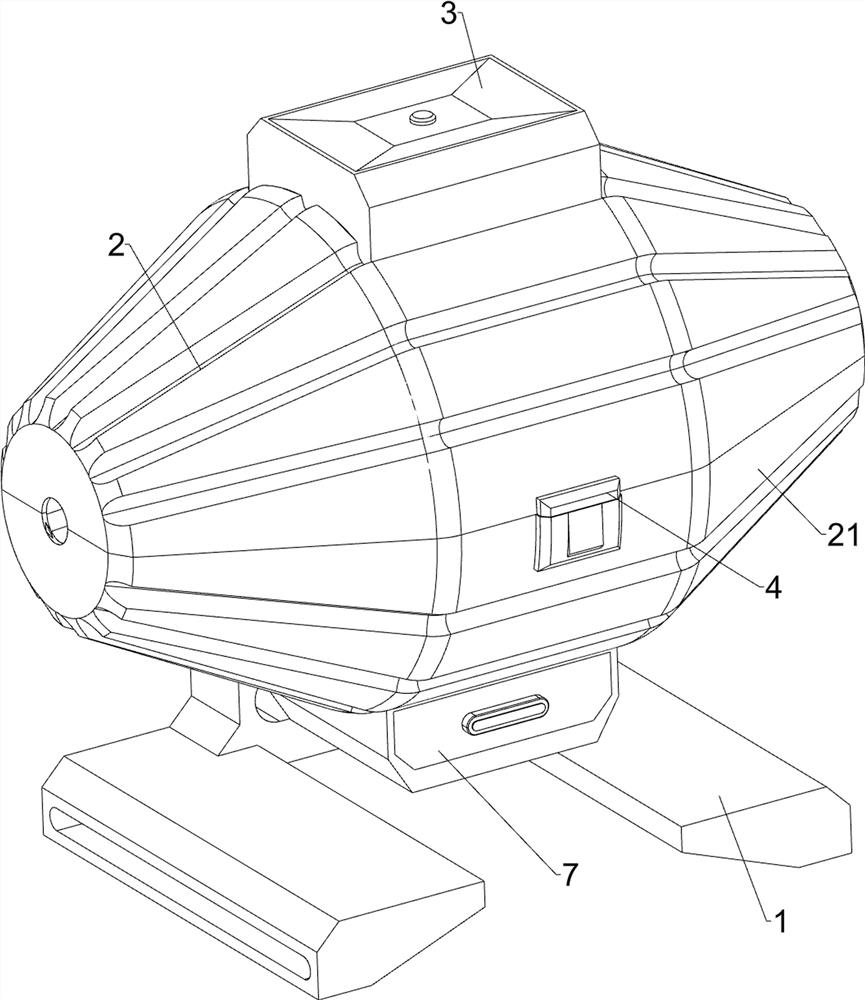

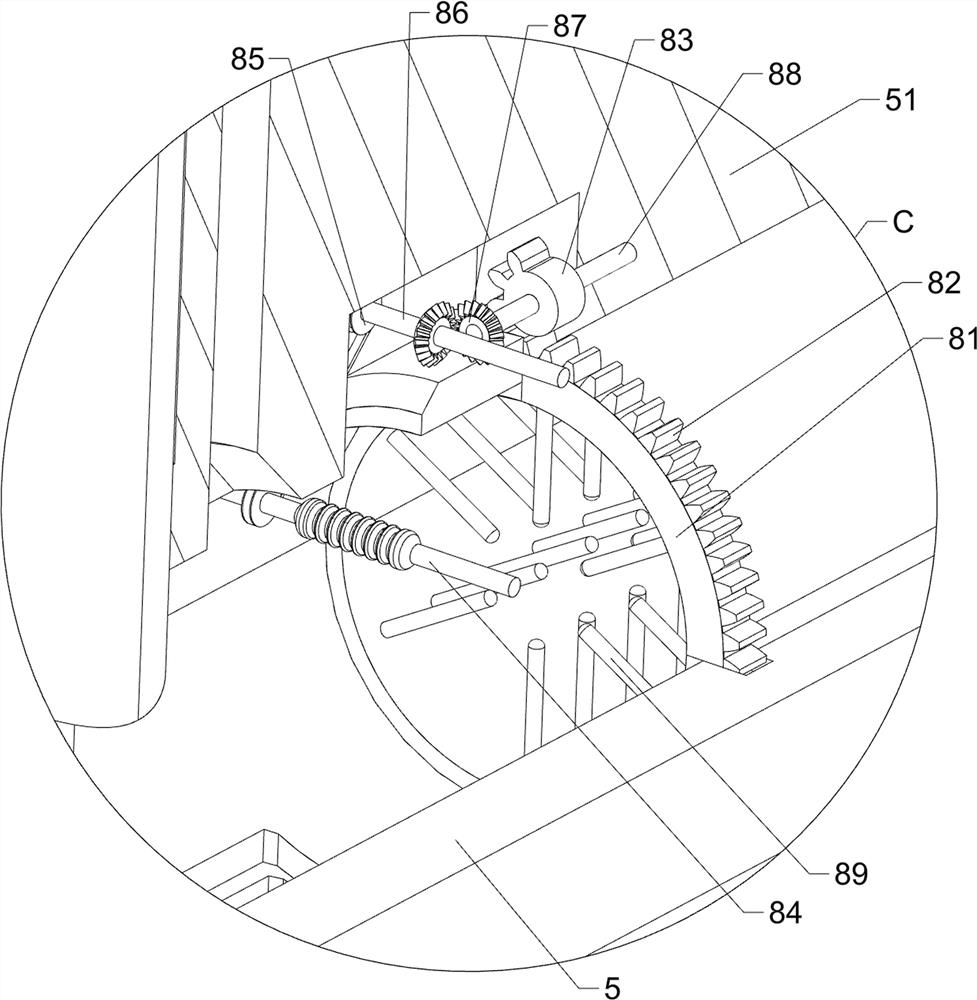

[0036]A device for evenly scraping oil on the surface of a cable, comprising a support frame 1, a first housing 2, a second housing 21, an oil storage frame 3, a block 4, an L-shaped semicircular guide plate 5, a T-shaped semicircular guide plate 51, an oil dripping Assembly 6, collection assembly 7 and smoothing assembly 8, see Figure 1-Figure 8 As shown, the top of the support frame 1 is installed with a second housing 21 by means of welding connection, and the middle of the upper part of the outer rear side of the second housing 21 is connected with the first housing 2 through hinge rotation, and the top of the first housing 2 The oil storage frame 3 is fixedly connected in the middle, and the bottom of the oil storage frame 3 is connected with a T-shaped semicircular guide plate 51. The middle of the right side of the inner bottom of the second housing 21 is installed with an L-shaped semicircular guide plate 5 by welding, and the L-shaped semicircular guide plate 5 is in...

Embodiment 2

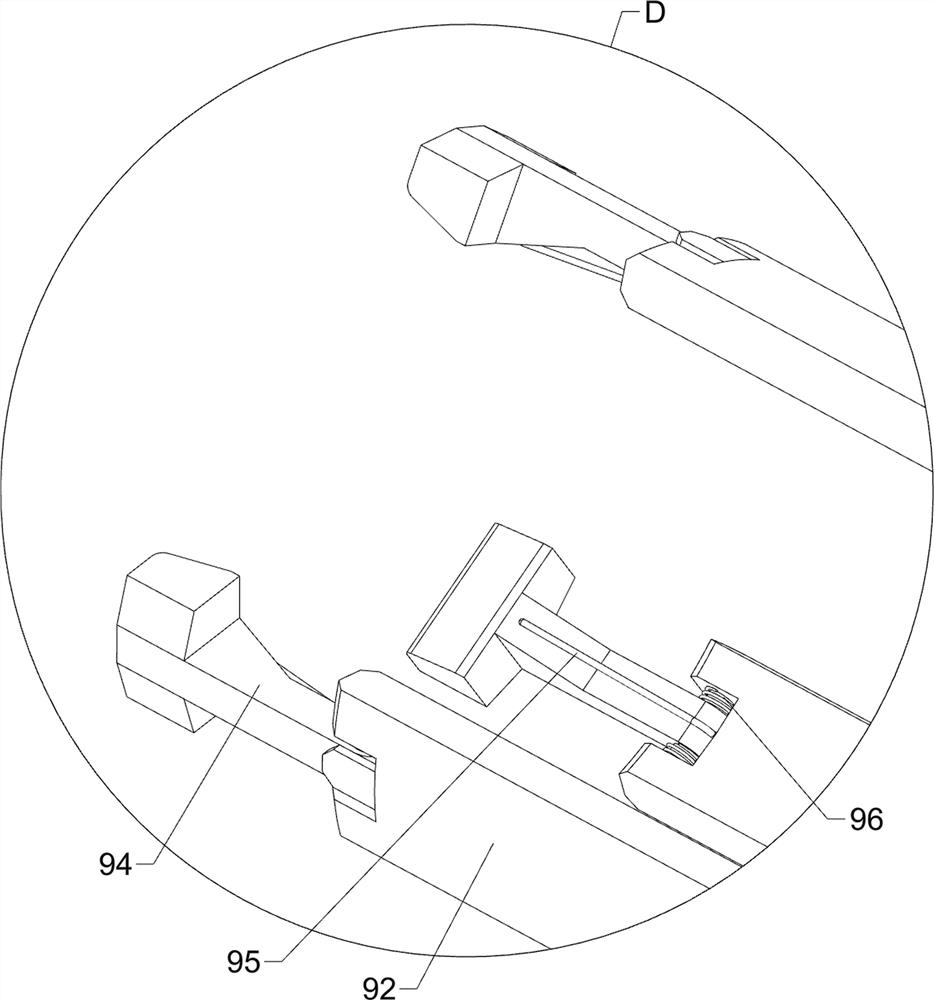

[0045] On the basis of Embodiment 1, it also includes a placement assembly 9, and the placement assembly 9 includes a first L-shaped push plate 91, a connecting frame 92, a second L-shaped push plate 93, a T-shaped clamp block 94, a pull wire 95, a torque Spring 96, guide rod 97 and elastic member 98, see figure 2 , Figure 9 , Figure 10 and Figure 11 As shown, the first connecting sleeve 81 is slidably connected with a connecting frame 92, and the middle of the right side surface of the connecting frame 92 is equipped with a first L-shaped push plate 91 through welding connection, and the right side of the first L-shaped push plate 91 A guide rod 97 is fixedly connected in the middle of the upper part of the side, and a second L-shaped push plate 93 is slidably connected between the bottom of the first L-shaped push plate 91 and the right part of the connecting frame 92, and the second L-shaped push plate 93 is sleeved on the On the guide rod 97, an elastic member 98 is...

Embodiment 3

[0048] On the basis of Embodiment 1 and Embodiment 2, an oil discharge assembly 10 is also included. The oil discharge assembly 10 includes an oil baffle 101, a second connecting sleeve 102 and a third spring 103. Please refer to figure 2 and Figure 12 As shown, there is a discharge opening in the middle of the left side of the upper part of the L-shaped semicircular guide plate 5. A second connecting sleeve 102 is installed between the left and right sides of the discharge opening of the L-shaped semicircular guide plate 5 by welding. The second connecting sleeve 102 The oil baffle plate 101 is connected in the middle sliding type, and the oil baffle plate 101 can block the oil in the L-shaped semicircular guide plate 5, and the third spring 103 is connected between the inner top of the oil baffle plate 101 and the top of the second connecting sleeve 102 .

[0049] Also includes a prompt assembly 11, the prompt assembly 11 includes a buoyancy block 1101, a second connectin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com