Desk capable of being overturned downwards

A technology for flipping tables and tables, which is applied in the field of office equipment and smart furniture. It can solve the problems that the flipping gap cannot be well eliminated, the stability of the folding table is not high, and the flipping grip is not in place, so as to improve the overall aesthetics, Ease of assembly and improved safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

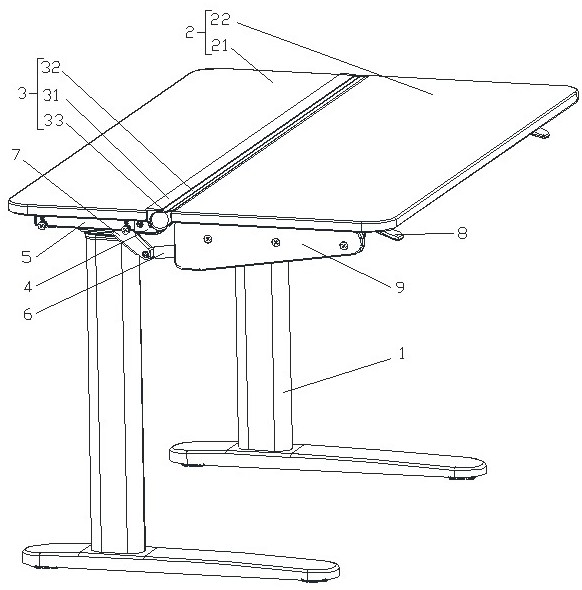

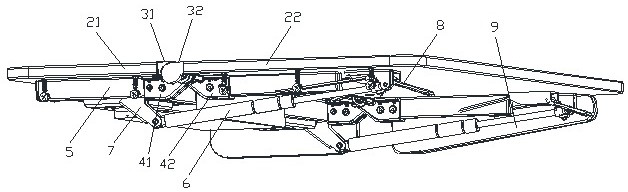

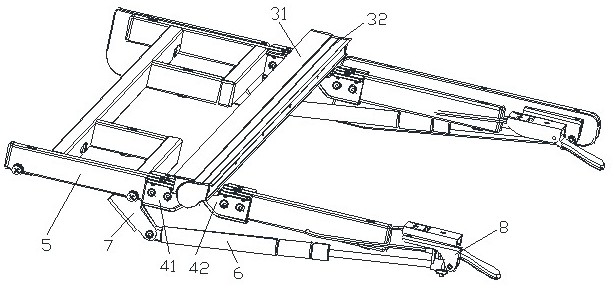

[0048] Such as figure 1 As shown, a table that can be turned down includes a table leg assembly 1 and a table board assembly 2. The table leg assembly 1 is a lifting table leg, and the table board assembly 2 is composed of a fixed table board 21 and a reversible table board 22. The fixed table board 21 is fixed on the table leg assembly 1, and the flip table 22 is rotatably connected to one side edge of the fixed table 21, the rotation angle of the flip table 22 is -130°~0°, the fixed table 21 and the flip table 22 The connection is provided with a connection assembly 3 that always covers the connection during the reversing stroke of the reversing table 22. The connection assembly 3 includes a fixed profile 31 fixed on the fixed table 21 and a flipper connected to the reversing table 22 to follow its action. The profile 32 has an overlapping joint with the fixed profile 31 during the action of turning over the profile 32 .

[0049] Such as figure 2 with image 3As shown, a...

Embodiment 2

[0056] The difference with Embodiment 1 is: as Figure 9 As shown, the two ends of the vertical section 311 of the fixed profile 31 extend horizontally to form a flange 314 enclosing the end of the fixed table 21, and the horizontal section 312 is formed by extending the flange 314 at the upper end of the vertical section 311 in the opposite direction. Such as Figure 10 As shown, the two ends of the vertical connecting portion 321 of the turning profile 32 respectively extend horizontally to form a connecting flange 325 enclosing the end of the turning table 22 , and the connecting flange 325 is connected to the horizontal transition portion 322 through a slope 326 .

[0057] The flange 314 and the connecting flange 325 are not only convenient for the connection and installation of the fixed profile 31 and the overturned profile 32, but also ensure that the joint will not be worn by external force.

Embodiment 3

[0059] The difference with Embodiment 2 is that: as Figure 11 As shown, a supporting member 10 is provided on the inner side of the turning profile 32 , and the upper surface profile of the supporting member 10 matches the inner wall profile of the turning profile 32 . The inner end of the support member 10 is provided with a barb portion 101 , and the end of the arc-shaped extension portion 323 is provided with an engaging section 3231 matched with the barb portion 101 . Specifically, such as Figure 12 As shown, a 7-shaped notch 102 is provided on the inner side of the support member 10, and a reverse 7-shaped barb 101 is formed at the bottom of the 7-shaped notch 102. The barb 101 and the notch 102 form an upper left end. In the receiving part of the opening, the clamping section 3231 has a stepped structure, which is limited by the opening after entering the receiving part through the opening.

[0060] The support member 10 can be placed at any position as required to p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com