Carbon fiber badminton racket and manufacturing method thereof

A badminton racket and carbon fiber technology, applied in rackets, string-through rackets, sports accessories, etc., to achieve a comfortable working environment, improved torsion resistance, and reduced racket shape

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0058] The following will be combined with Figure 1-7 The present invention is further described.

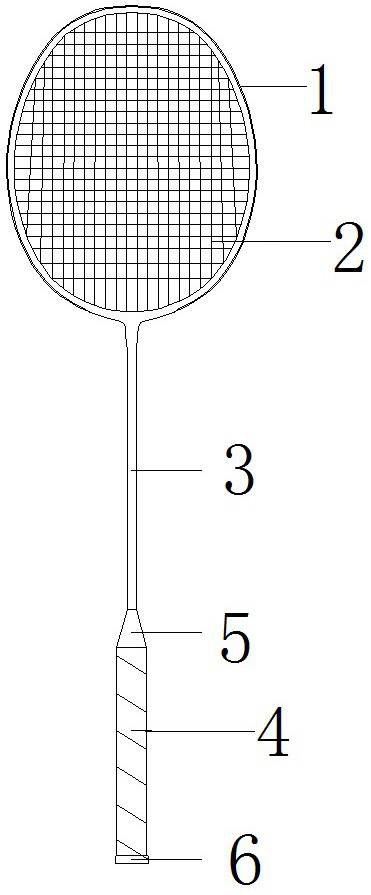

[0059] Refer to attached figure 1 , a carbon fiber badminton racket has a racket frame 1, the racket frame 1 has a grid-like taut string 2, the tail end of the racket frame 1 is rigidly connected to the racket shaft 3, and the tail end of the racket shaft 3 is connected to a handle 4 ; A front cover 5 is sheathed at the junction of the handle 4 and the racket rod 3;

[0060] Further, a rear cover 6 is sheathed at the tail end of the handle 4 to prevent the bottom of the handle 4 from being bumped accidentally.

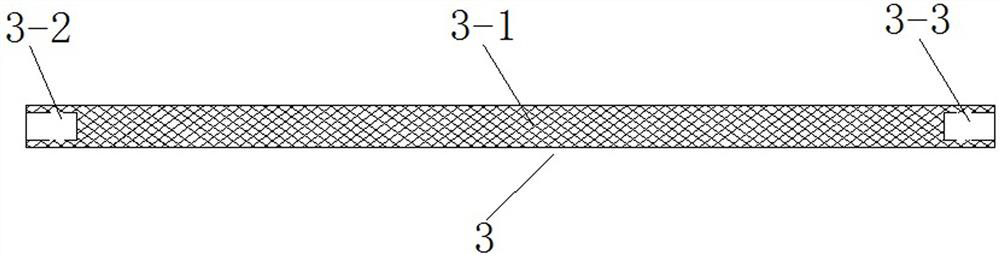

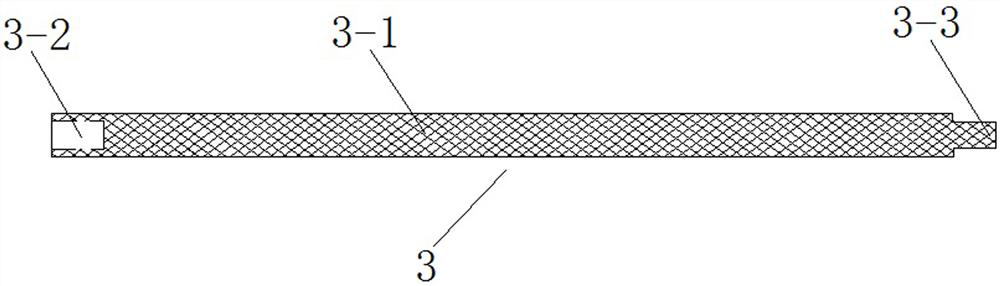

[0061] Refer to attached figure 2 , attached image 3 , the racket rod 3 has a rod body 3-1, the rod body 3-1 is a solid or hollow tube with fillers, and the upper and lower ends of the rod body 3-1 have an upper extension section 3-2 and a lower extension section 3-3 respectively , the racket shaft 3 is formed by solidification of carbon fiber; any end of the upp...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Outer diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap