Plate and strip rolling mill roller shape measuring device and measuring method

A technology of measuring device and roll, which is applied in the direction of length measuring device, metal rolling, metal rolling, etc., can solve the problems of measuring accuracy affected by the environment, affecting production scheduling, and easy-rolling equipment, and achieves simple structure, convenient operation, Facilitate the effect of correct reading

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

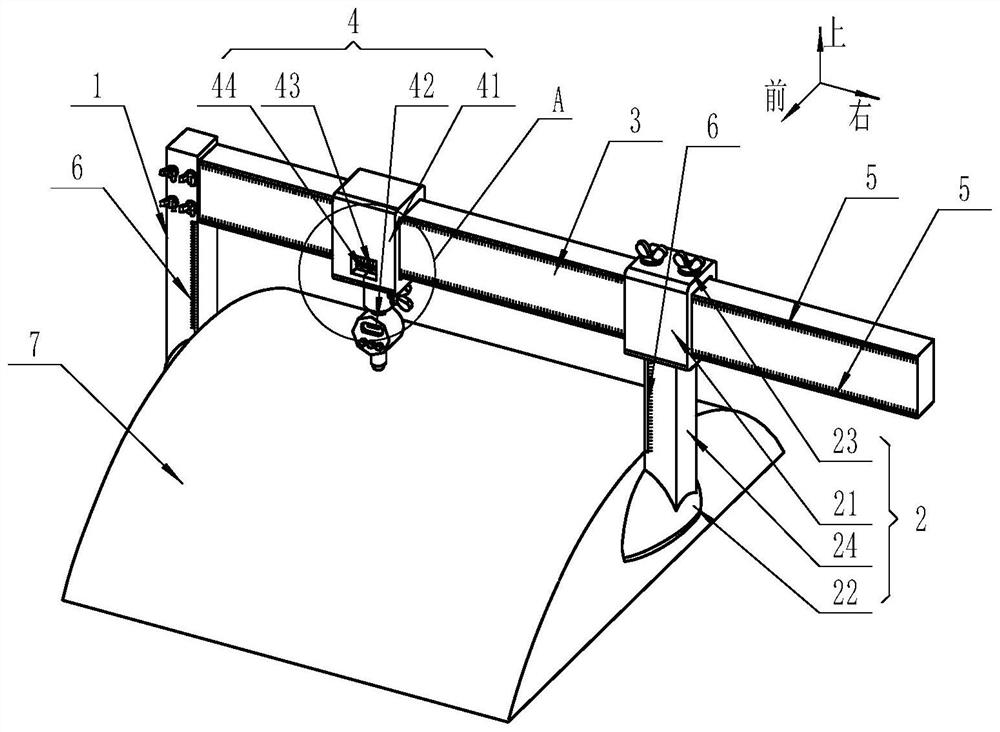

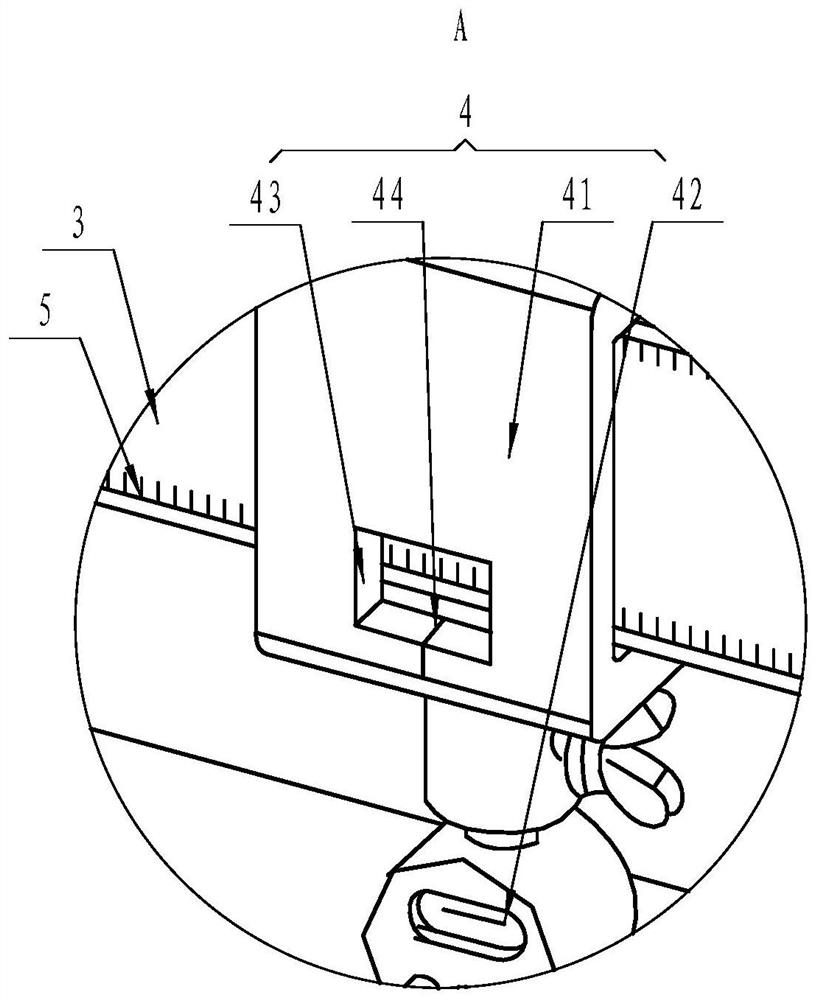

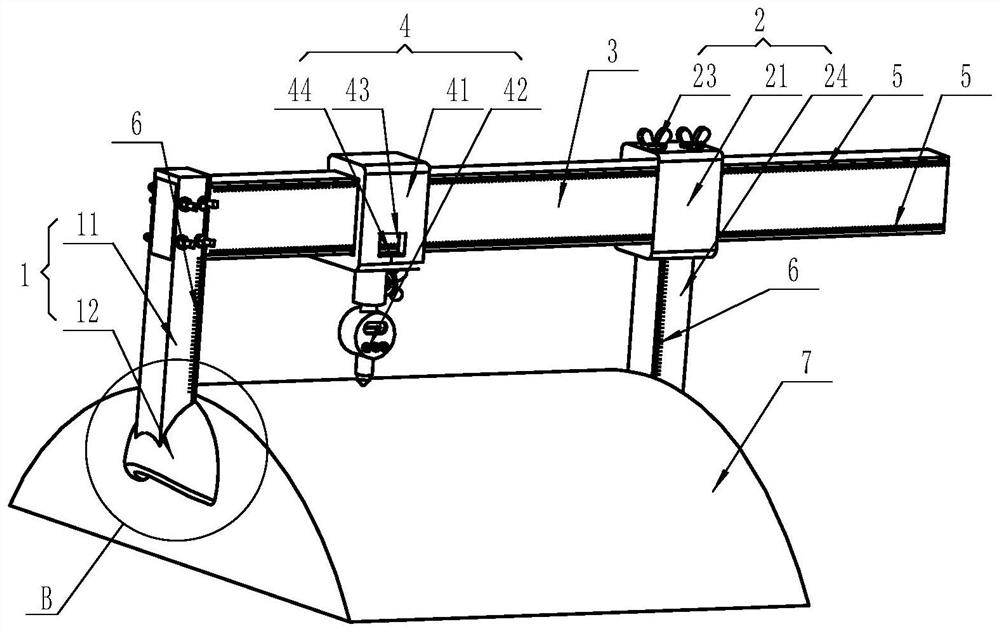

[0038]The following is combined with the attached Figure 1-7 The present invention will be further elaborated.

[0039] For ease of description, coordinate systems such as are defined Figure 1 shown, and in the left and right directions for the horizontal direction, the front and back directions for the longitudinal direction, the up and down directions for the vertical direction.

[0040] Embodiments of the present invention discloses a strip rolling mill roll shape measuring device and measurement method. Reference Figure 1 and Figure 3 , a strip rolling mill roll measuring device, comprising a horizontally set ruler carriage 3, one end of the ruler carriage 3 vertically provided with a fixed bracket 1, the other end is provided with a horizontal sliding swim bracket 2, the fixed bracket 1 and the swimming bracket 2 are attached to the end face of the roll 7, between the fixed bracket 1 and the swimming bracket 2 there is also a measuring unit 4, the measuring unit 4 includes...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com