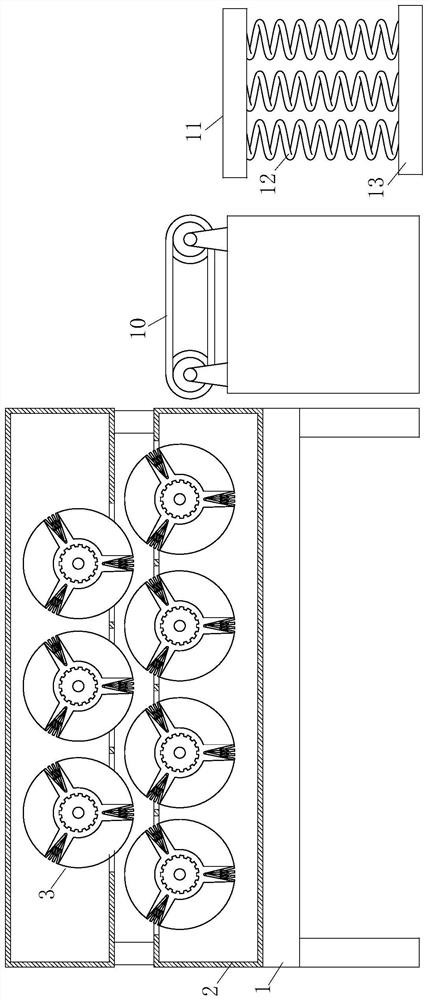

Metal plate leveling machine

A metal sheet and leveling machine technology, applied in metal processing equipment, forming tools, manufacturing tools, etc., can solve the problems of affecting work efficiency, time-consuming and labor-intensive, and long duration of rotating the adjustment handle, so as to reduce labor intensity. , Save time consumption, improve the effect of action efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

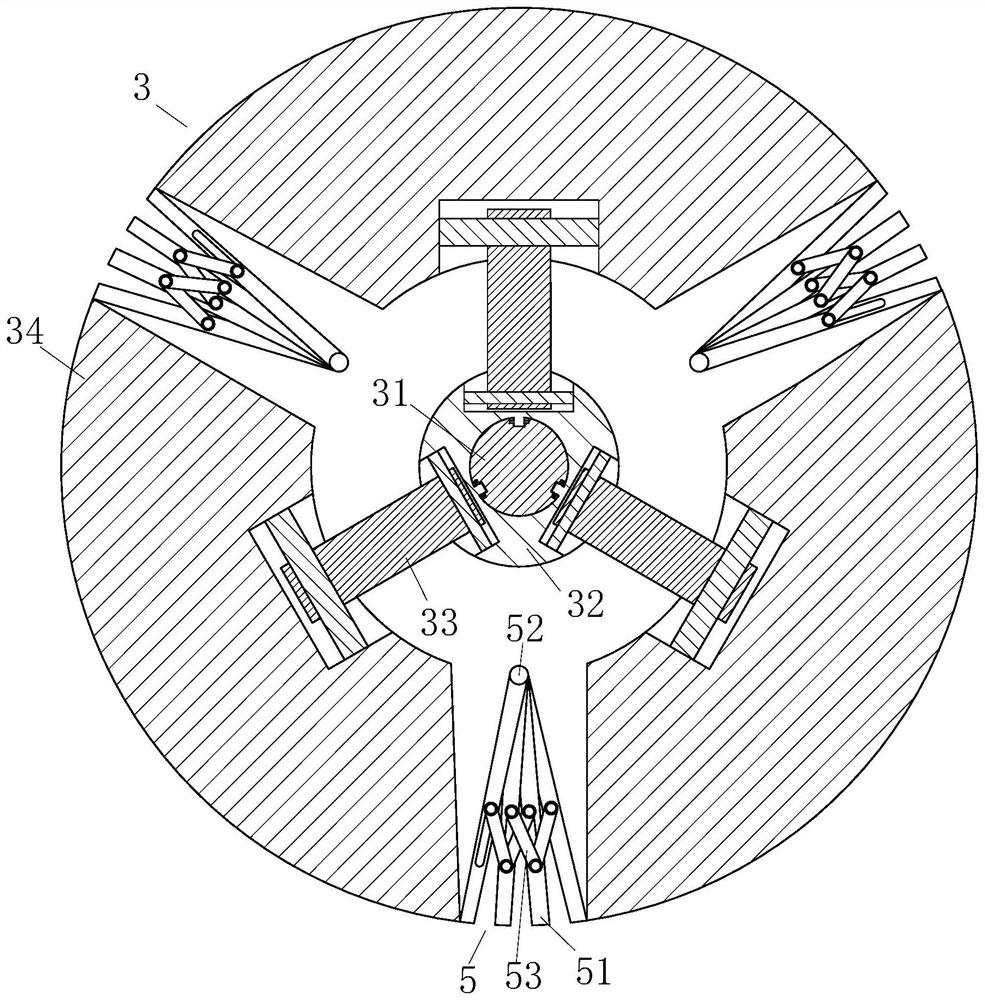

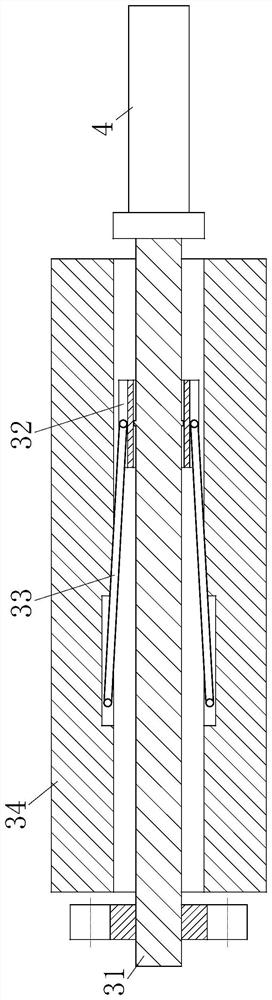

[0044] As an embodiment of the present invention, the roll assembly 3 includes:

[0045] A rotating shaft 31, the rotating shaft 31 is located in the middle of the roll assembly 3, and the rotating shaft 31 is connected to the push-pull rod 4 through a coupling;

[0046] A sleeve 32, the inner surface of the sleeve 32 is slidingly connected with the rotating shaft 31;

[0047] Retractable rods 33, a plurality of retractable rods 33 are rotatably connected to the outer surface of the sleeve 32;

[0048] Semi-annular roller 34, the inner surfaces of a plurality of said semi-annular rollers 34 are all rotatably connected with retractable rod 33;

[0049] By adopting the above technical scheme, when the thickness of the metal sheet is small, the staff pushes the push-pull rod 4 forward, and the push-pull rod 4 is pushed forward to the middle of the chassis 2, and the push-pull rod 4 is forced to move forward, driving the rotating shaft 31 moves forward, and the rotating shaft 31 d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com