Method for producing metal composite foil for battery cell and motor vehicle having battery cell

A technology of battery cells and cell stacks, applied in battery electrodes, non-aqueous electrolyte battery electrodes, lithium batteries, etc., which can solve the problems of limited electrolyte release rate, expensive and complicated battery cell manufacturing, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

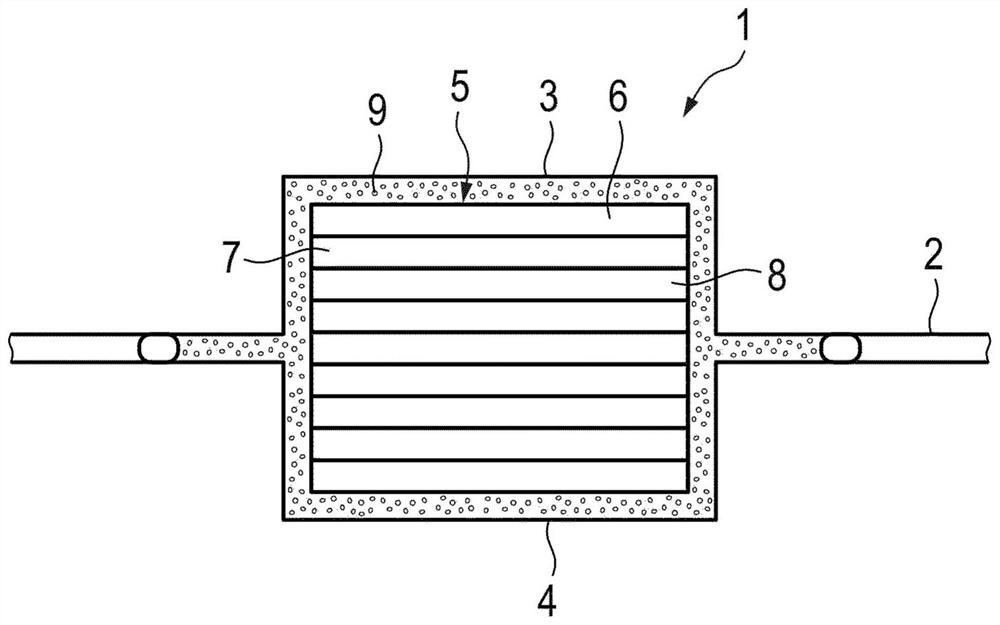

[0059] at Figure 1 Medium schematic and side section diagram illustrating the battery cell 1. Battery unit 1 has a shell cover 2, the shell cover 2 consists of a battery pack film 3 in the upper part and a battery pack film 4 in the lower part. Battery pack films 3 and 4 are sealed to each other by welds. The unit stack 5 composed of alternating stacks of anodes 6, divider layer 7 and cathode 8 is located in the housing cover 2. Here, the unit stack 5 is surrounded by electrolyte 9. In particular, electrolyte 9 is also present in the pores or recesses of the anode 6, the dividing layer 7 and cathode 8 and may also accommodate lithium ions of the lithium ion source there when desired.

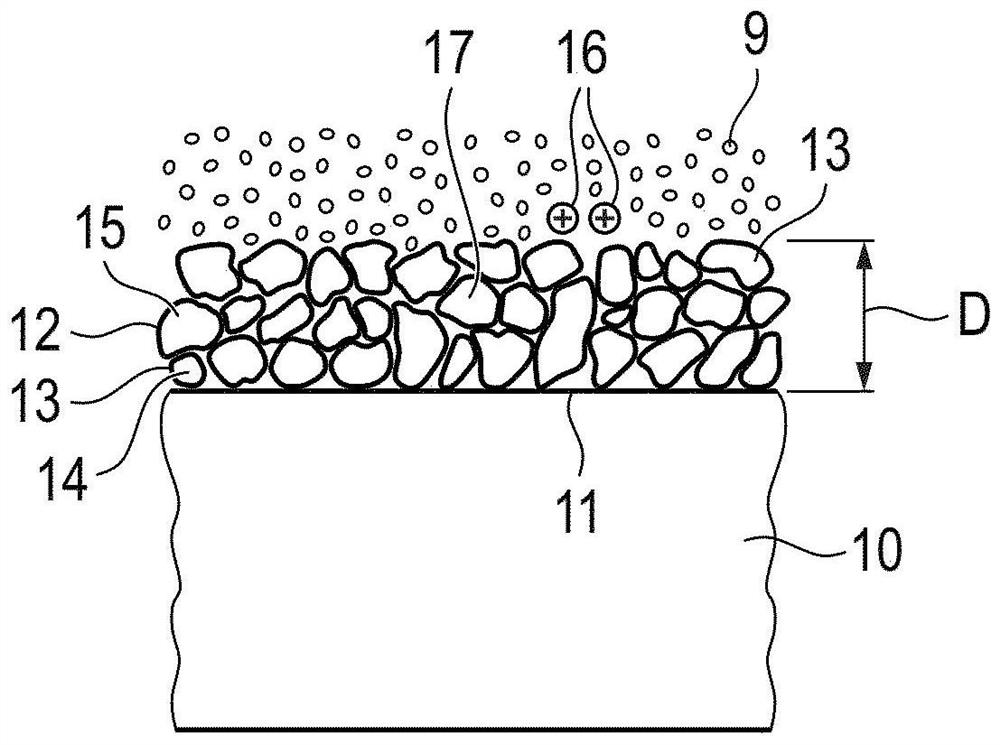

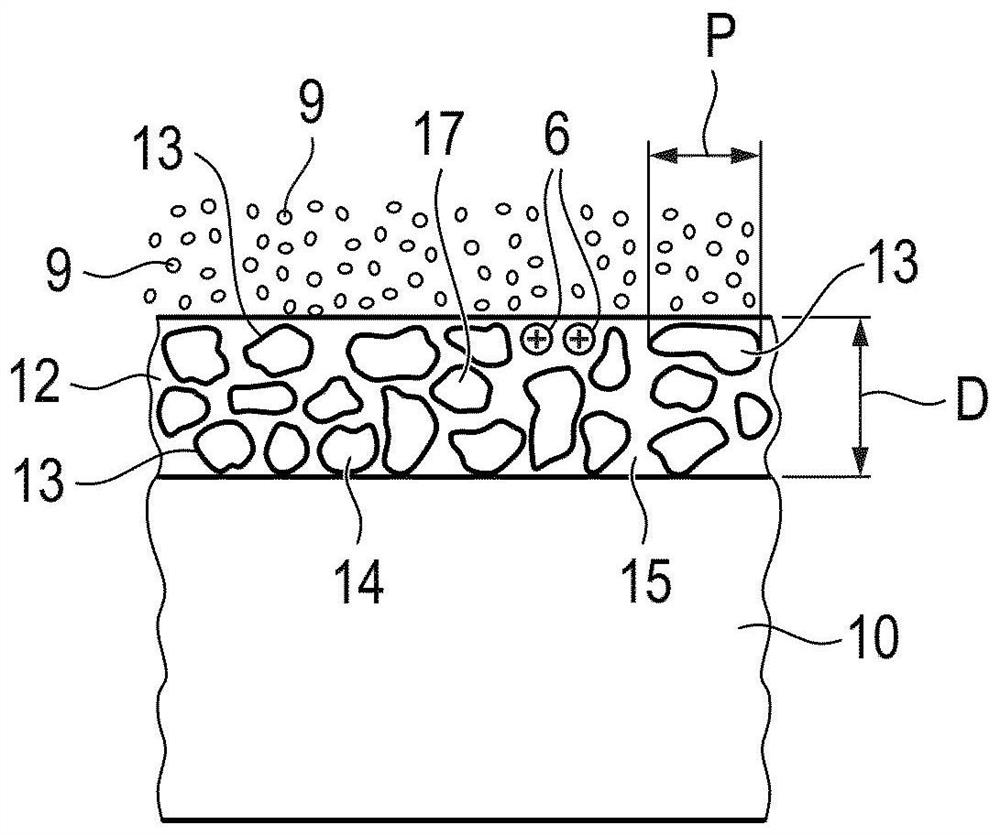

[0060] Figure 2 To show a member of the battery cell 10 in a magnified cross-sectional view. Member 10 may be, for example, housing cover 2, anode 6, separation layer 7, cathode 8 or other components of the battery unit 2 disposed within the housing cover 2. Layer 12 is applied to the surface 11 in c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Layer thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap