Gear assembly for a motor vehicle seat mechanism, comprising a vehicle seat actuator and a vehicle seat comprising the actuator

A vehicle seat and actuator technology, applied in the field of vehicle seat actuators and gear assemblies, can solve problems such as occupant unpleasantness and reduced actuator efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

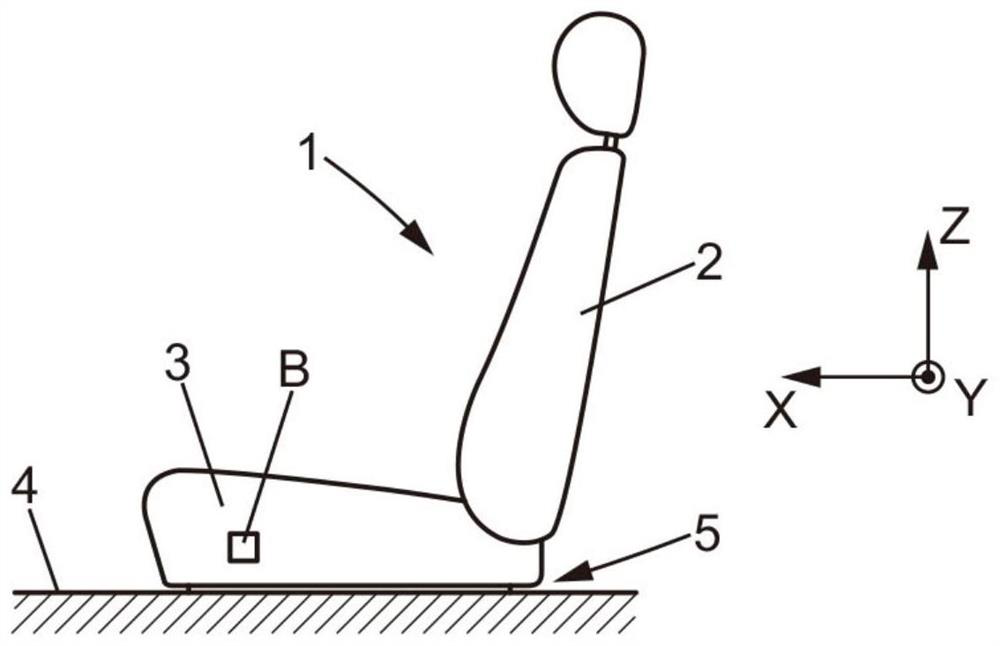

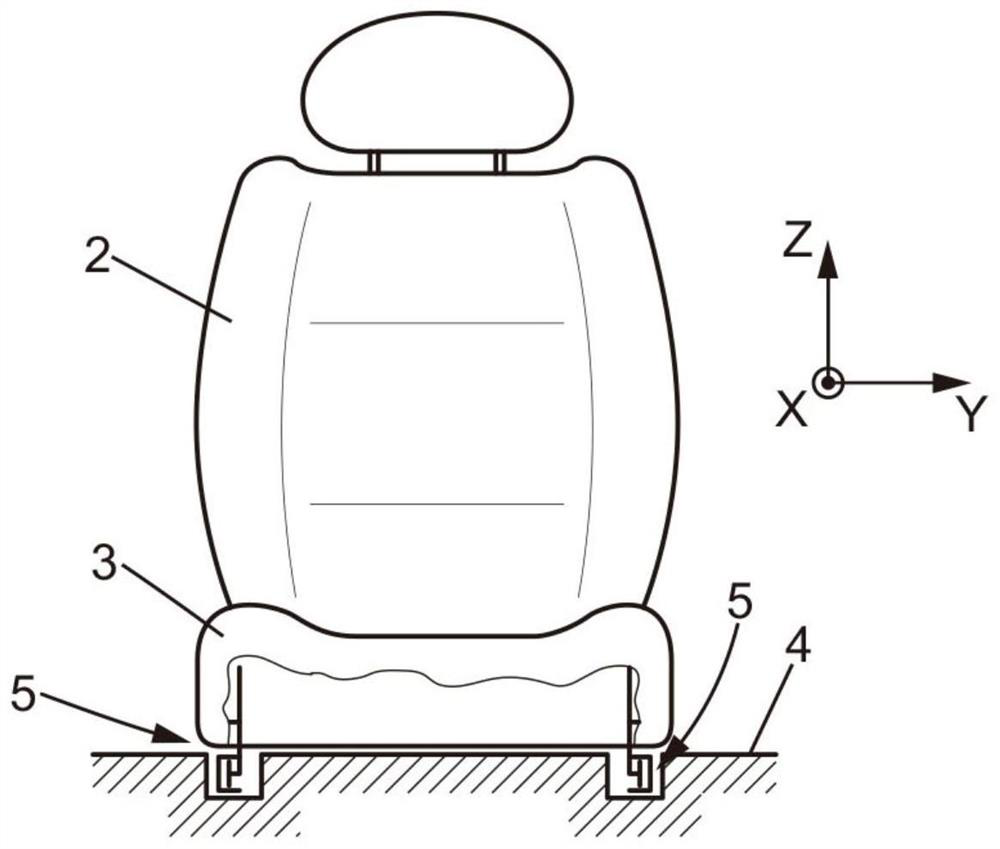

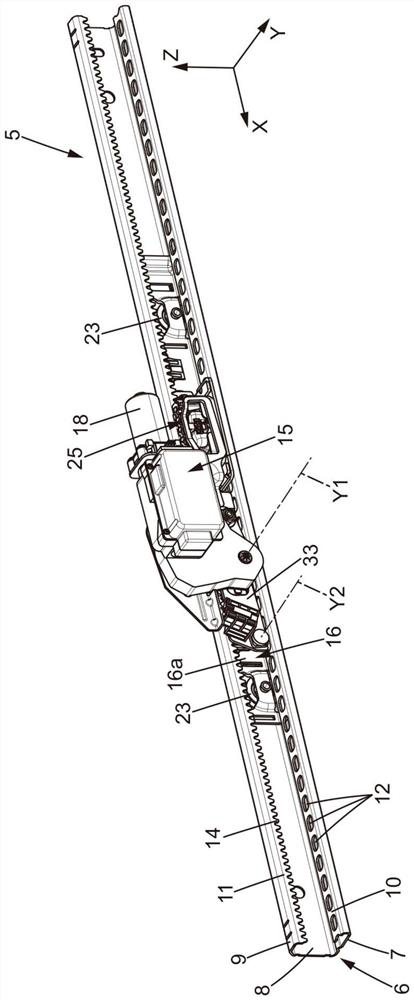

[0076] In the various figures, the same reference numerals refer to the same or similar elements.

[0077] For the sake of brevity, only features that are useful for understanding the described embodiments are only shown in the drawings and / or described in detail below, in particular locking and / or control mechanisms not shown and described below, the described Embodiments are compatible with common mechanisms.

[0078] In the following description, when referring to absolute positional qualifiers, such as the terms "front", "back", "upper", "bottom", "left", "right", etc., or relative positional qualifiers, such as the terms "above", "below", "upper", "lower", etc., or directional qualifiers such as "horizontal", "vertical", etc., unless otherwise specified, shall refer to the drawings or the seat in its normal use the direction of the location.

[0079] As described below, the longitudinal direction X is the longitudinal direction of the seat. The longitudinal direction o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com