Vertical shaft construction method under environment sensitive area or space limited condition

A construction method and technology for sensitive areas, which can be used in shaft equipment, well sinking, and earth-moving drilling and mining, etc., and can solve problems such as difficulties in the construction of shafts connecting the ground and underground tunnels.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

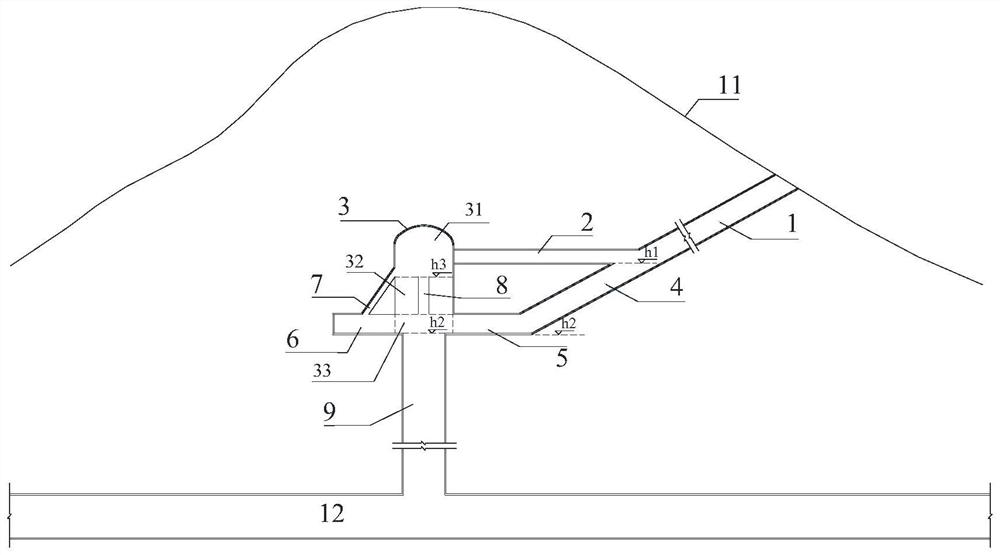

[0057] Before the shaft is constructed and excavated, it is necessary to determine the connection position between the shaft and the underground tunnel, and the position of the wellhead for excavation of the inclined shaft according to the design and construction documents and the on-site geological survey. The position of the wellhead of the inclined well excavation can be selected outside the environmentally sensitive area, and at the same time avoid the special environmental conditions with limited space. Any achievable manner in the prior art can be used to determine the connection position between the shaft and the underground tunnel and the position of the wellhead for excavation of the inclined shaft.

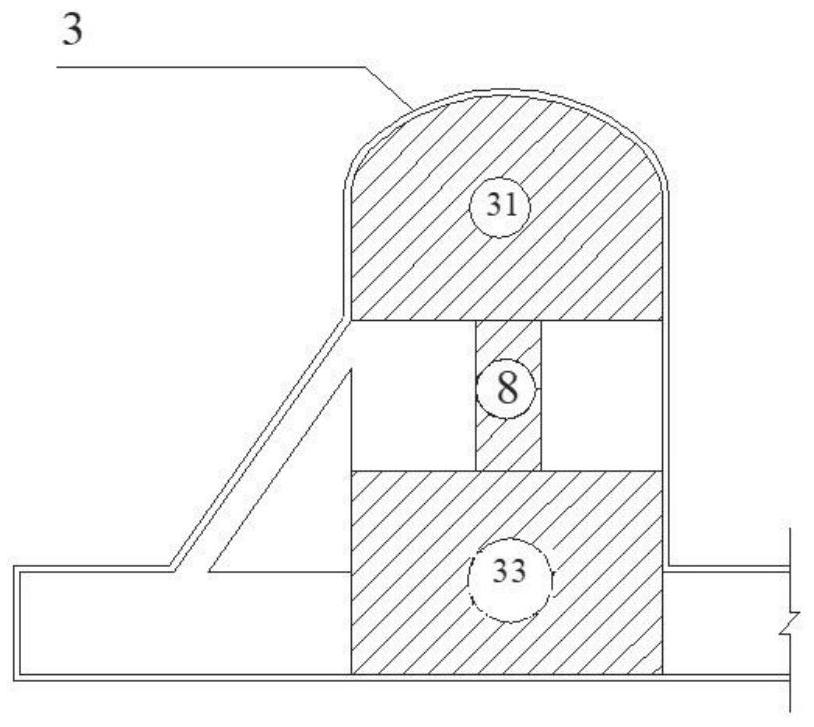

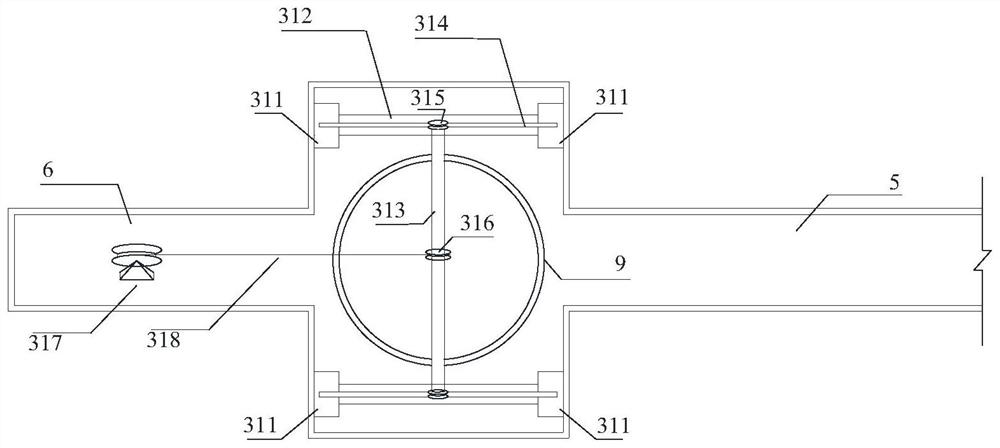

[0058] After the location is determined, in the actual construction of the shaft, it is also necessary to set up a shaft operation area in the underground rock and soil layer above the downward excavation of the shaft to provide the construction equipment with work, turno...

Embodiment 2

[0114] This embodiment provides a shaft for connecting ground and underground tunnels, which is constructed by adopting the shaft construction method provided in Embodiment 1 in an environmentally sensitive area or under space-limited conditions.

[0115] The built shaft, the maintenance and construction auxiliary channels formed during the well construction process, can be used as auxiliary backup channels for the ventilation of the underground tunnel. When the flat tunnel is blocked unexpectedly, the underground tunnel can still be ventilated with the outside through the maintenance and construction auxiliary channels. .

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com