Static bending force detection device of FBC circuit board

A detection device, static bending technology, applied in the direction of measuring device, using a stable bending force to test the strength of materials, instruments, etc., can solve the problems of easy injury to the human body, and achieve the effect of improving accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

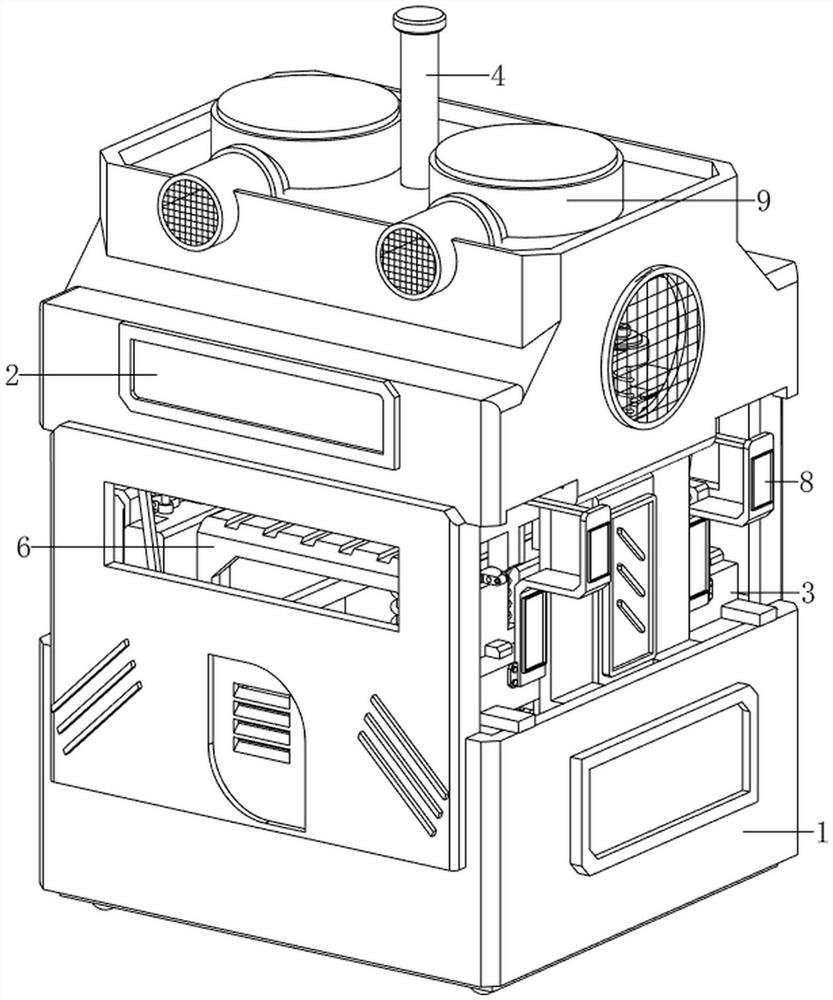

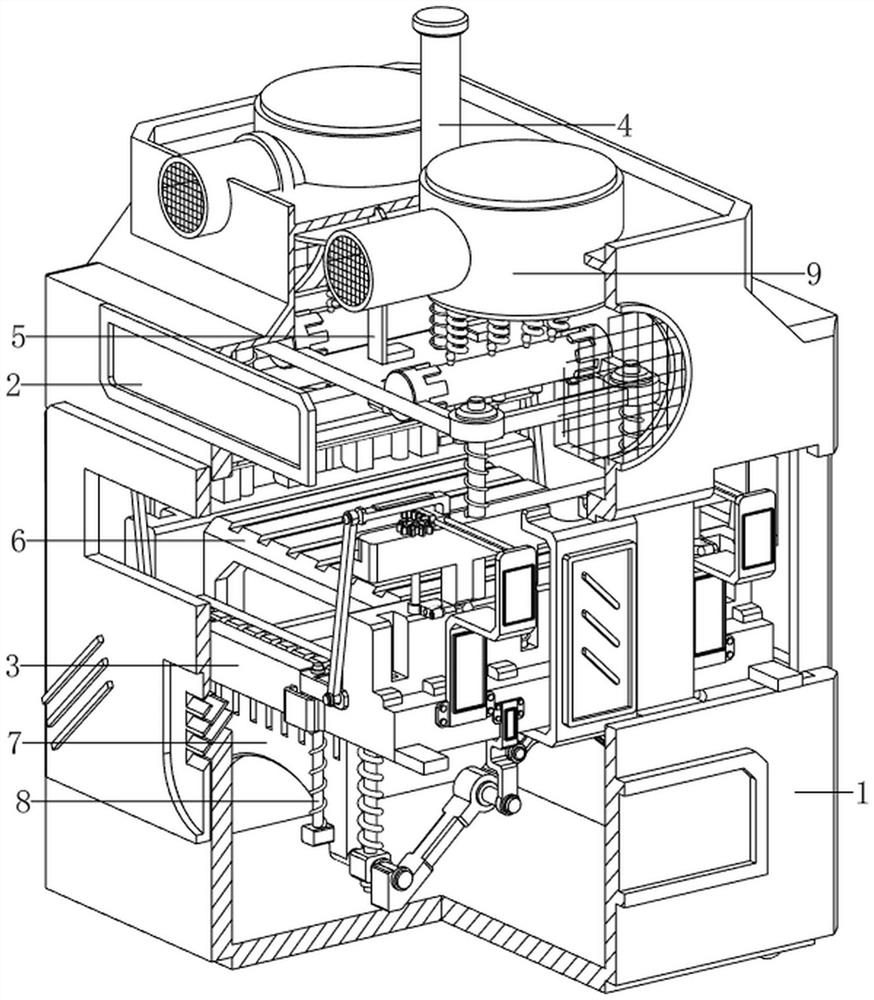

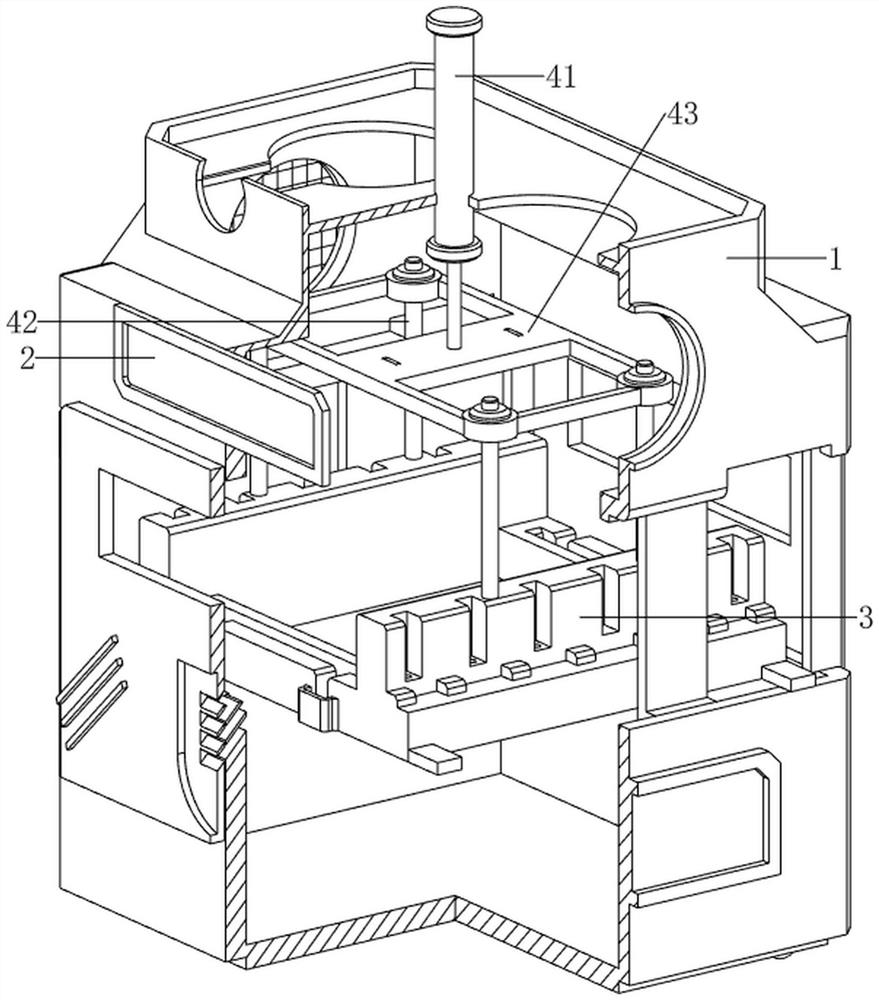

[0079] A static bending force detection device for FBC circuit boards, now refer to Figure 1-2 , including an installation casing 1, a display panel 2, a placing plate frame 3, a pressing mechanism 4 and a detection mechanism 5, a display panel 2 is provided on the upper side of the front part of the installation casing 1, and the display panel 2 is electrically connected to the control module, and the installation The housing 1 is provided with a placing plate frame 3, the placing plate frame 3 is used for holding circuit boards, and a pressing mechanism 4 is arranged between the placing plate frame 3 and the installation casing 1. The pressing mechanism 4 is used to drive the detecting mechanism 5, and The pressure mechanism 4 is provided with a detection mechanism 5 .

[0080] Reference now figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Image 6 , Figure 7 , Figure 8 , Figure 9 , Figure 10 , Figure 11 and Figure 18 The pressing mechanism 4 incl...

Embodiment 2

[0084] On the basis of Example 1, now refer to figure 1 , figure 2 , Figure 8 , Figure 9 , Figure 10 , Figure 11 , Figure 12 , Figure 13 , Figure 14 and Figure 15 , also includes a stabilizing mechanism 6, the stabilizing mechanism 6 includes a third spring 61, a pressure block 62, a connecting plate 63, a fourth spring 64, a third sliding rod 65 and a placement rack 66, the two first sliding rods on the same side A pressure block 62 is slidably arranged between 42, the pressure block 62 is slidably connected with the placing plate frame 3, and a third spring 61 is connected between the upper and rear sides of the pressure block 62 and the moving frame 43, and the third spring 61 has four The third spring 61 is wound on the first sliding rod 42, the outer sides of the two pressing blocks 62 are provided with connecting plates 63, and a placing frame 66 is welded between the two connecting plates 63, and the placing frame 66 slides with the placing plate frame ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com