Weak current engineering equipment maintenance monitoring system and monitoring method

A technology of equipment maintenance and weak current engineering, applied in the direction of comprehensive factory control, measuring electricity, electrical components, etc., can solve the problems of inconvenient equipment maintenance, inconvenient quick query of faulty equipment, etc., and achieve the effect of improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] The embodiments of the present invention are described below by specific embodiments, and those skilled in the art can easily understand other advantages and effects of the present invention from the contents disclosed in this specification.

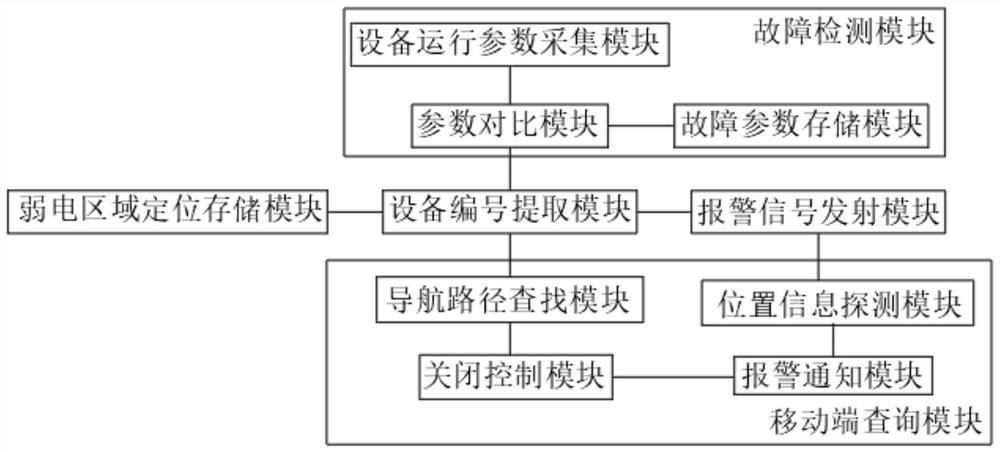

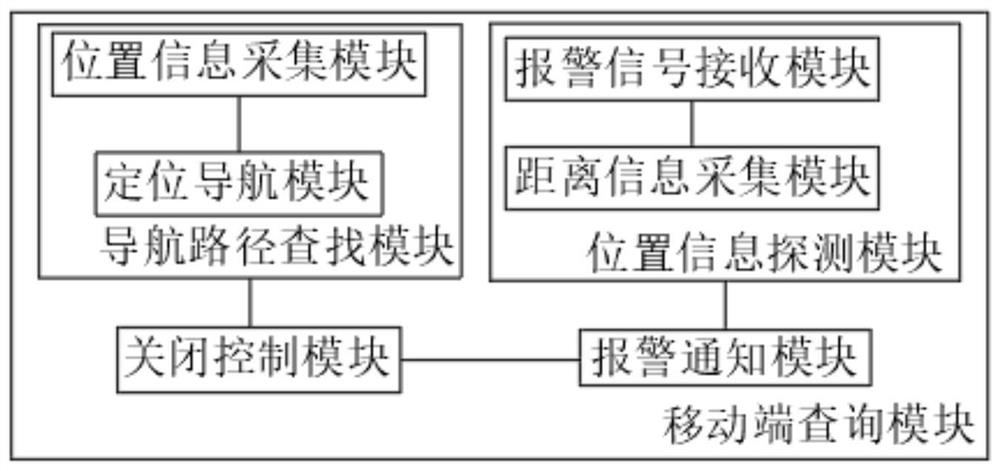

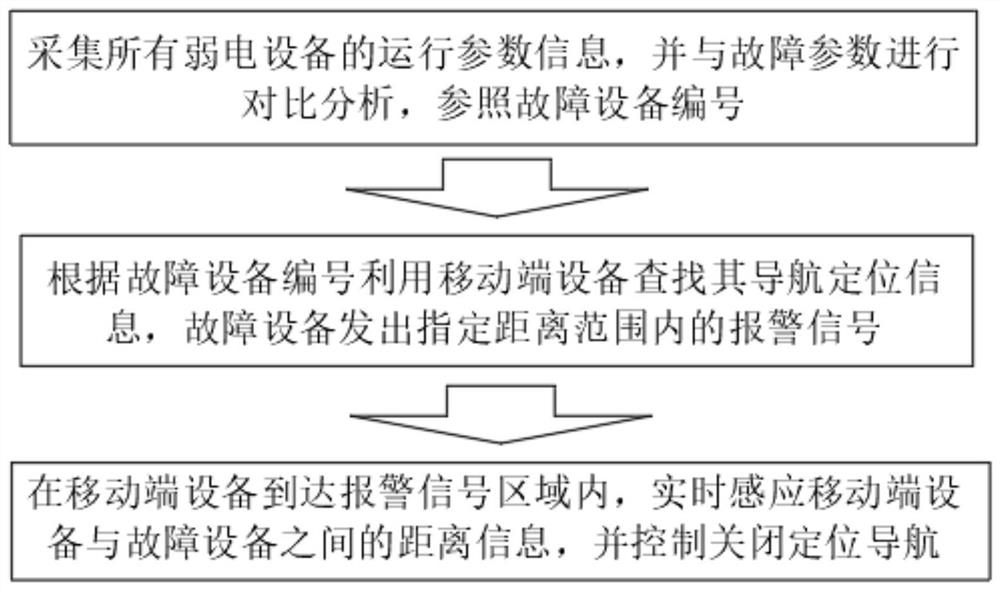

[0038] see Figure 1 to Figure 2 . The invention provides a technical scheme: a weak current engineering equipment maintenance monitoring system, comprising a fault detection module, an equipment number extraction module, an alarm signal emission module, a mobile terminal query module and a weak current area location storage module;

[0039] The fault detection module is used to compare and detect the fault operating parameters by collecting the operating parameter information of each weak current equipment;

[0040] The equipment number extraction module is used to extract the number information of the running faulty equipment;

[0041] The alarm signal transmitting module is used for the faulty equipment to issue an alarm sign...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com