Linkage type press-in device

A press-in device and linkage technology, applied in the field of press-fitting mechanism, can solve the problems of low work efficiency, high cost, and many actions, and achieve the effect of high work efficiency, simple control and smooth action

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

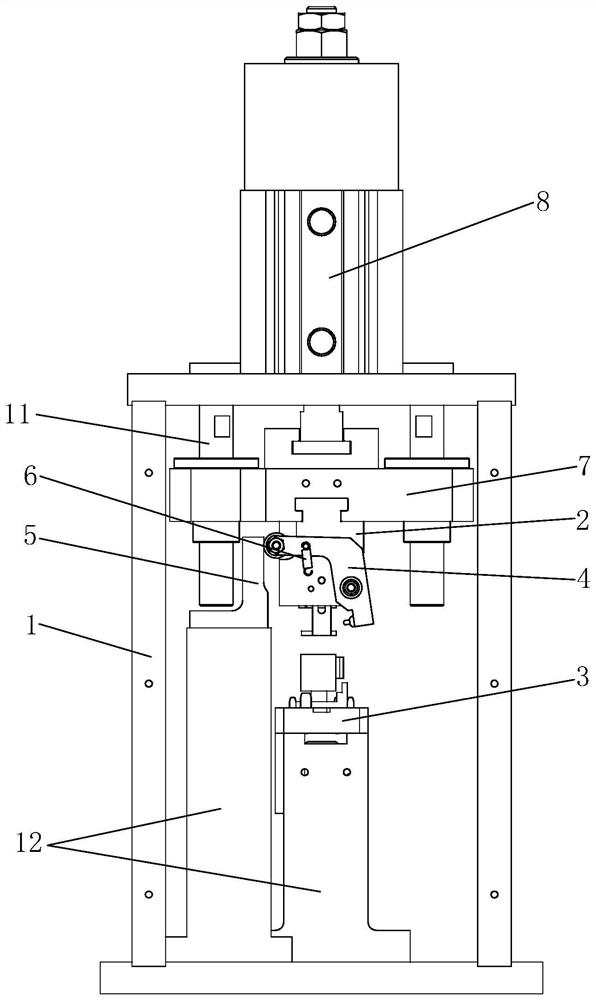

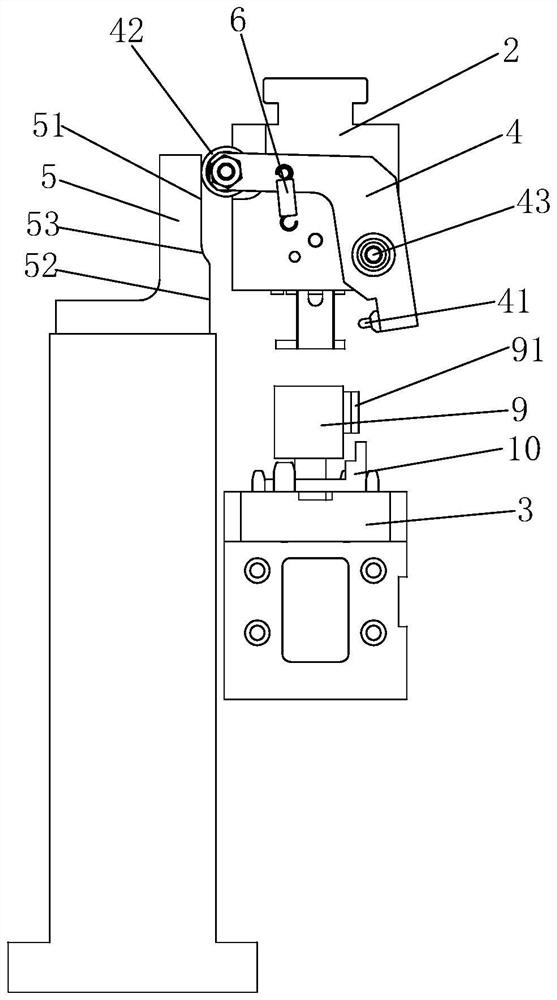

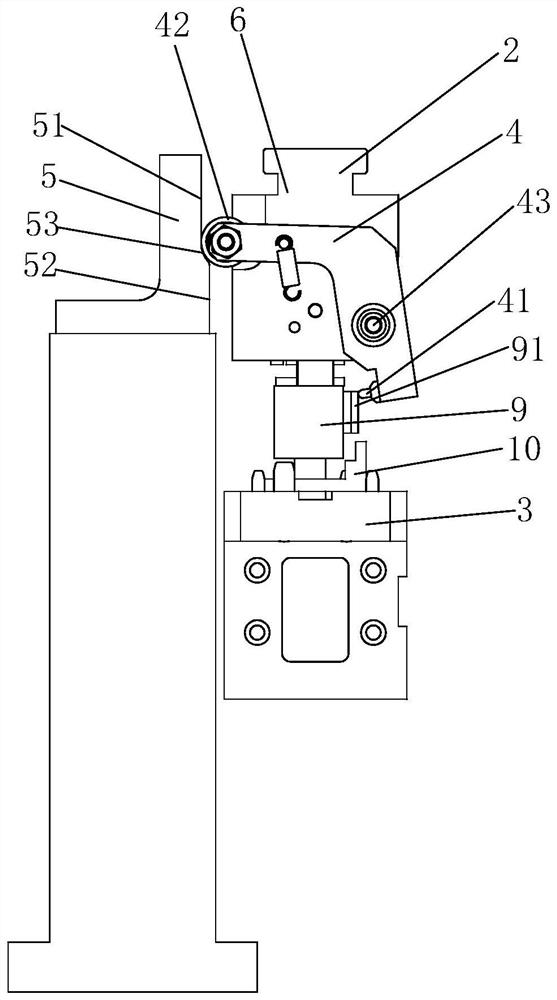

[0024] See Figure 1-Figure 4 As shown, a linkage type press-in device of the present invention includes a frame 1, a power mechanism, a lower pressing member 2 for press-fitting a first part on a second part, and a lower pressing part 2 for carrying the first part, For the support seat 3 of the second component, the power mechanism is arranged on the frame 1 and drives the lower pressing piece 2 to move downward or upward. The supporting seat 3 is located directly below the lower pressing piece 2 . The present invention also includes a side pressing mechanism, the side pressing mechanism includes a side pressing swing member 4 and a trigger member arranged at a designated position, the side pressing swing member 4 is rotatably connected to the lower pressing member 2, and the side pressing swing member 4 is rotatably connected to the pressing member 2. The swinging member 4 moves down with the lower pressing member 2 until the first part is pressed into the second part, and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com