Drain valve assembly with self-induction leakproofness

A drain valve, self-sensing technology, used in applications, climate sustainability, textiles and papermaking, etc., can solve problems such as poor user experience affecting product reliability and brand trust, screw caps not tightly closed, and inconvenient maintenance. Achieve the effect of improving customer experience, improving reliability, and facilitating maintenance and use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The present invention will be further described below in conjunction with the accompanying drawings.

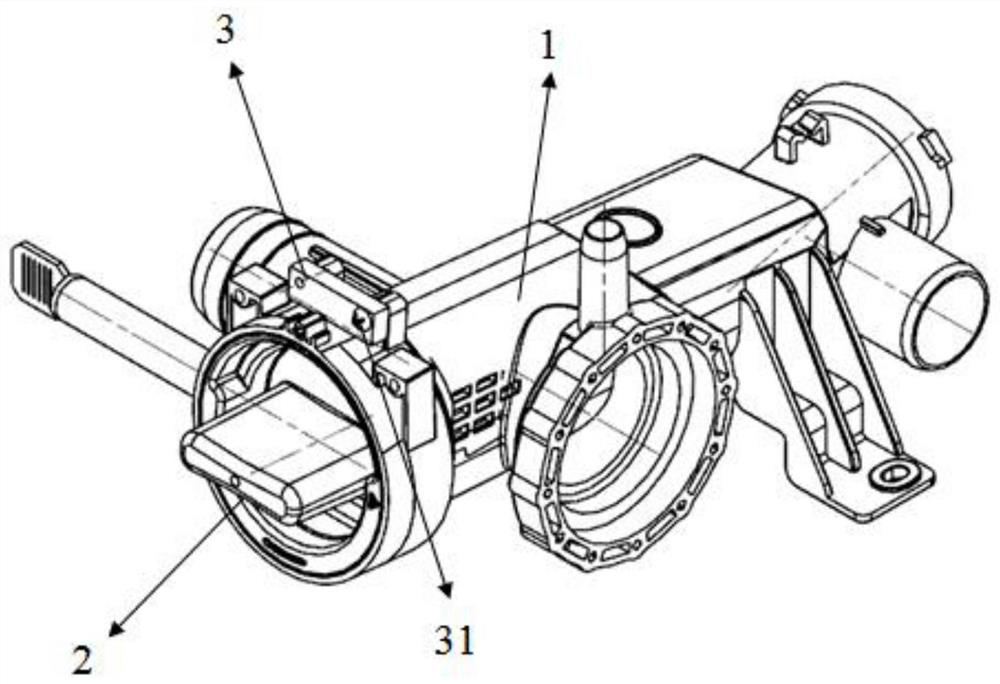

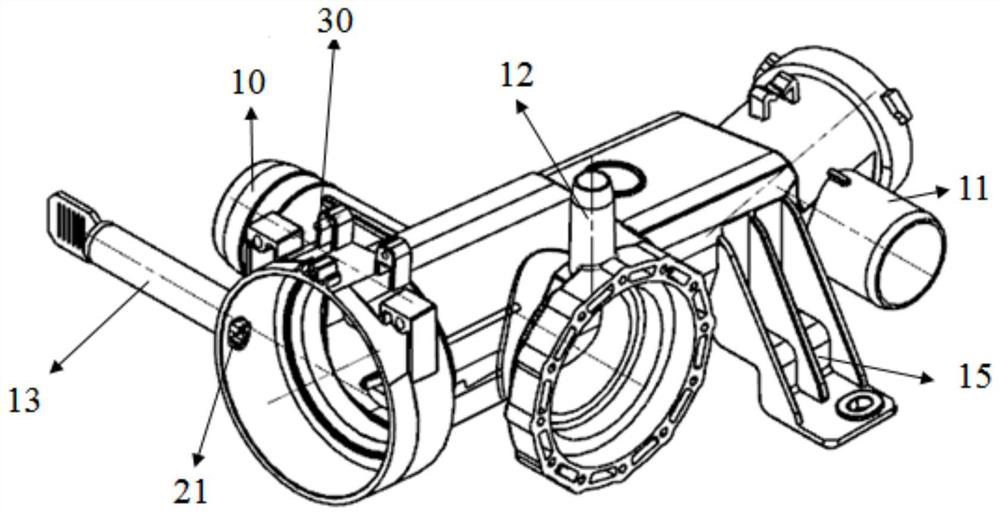

[0033] The drain valve assembly with self-induction airtightness of the present invention includes a drain valve body 1, a self-induction capping assembly 2 mounted with the drain valve body 1, and a drain valve body 1 for sensing the capping position feedback for draining Magnetic switch 3 for valve sealing information.

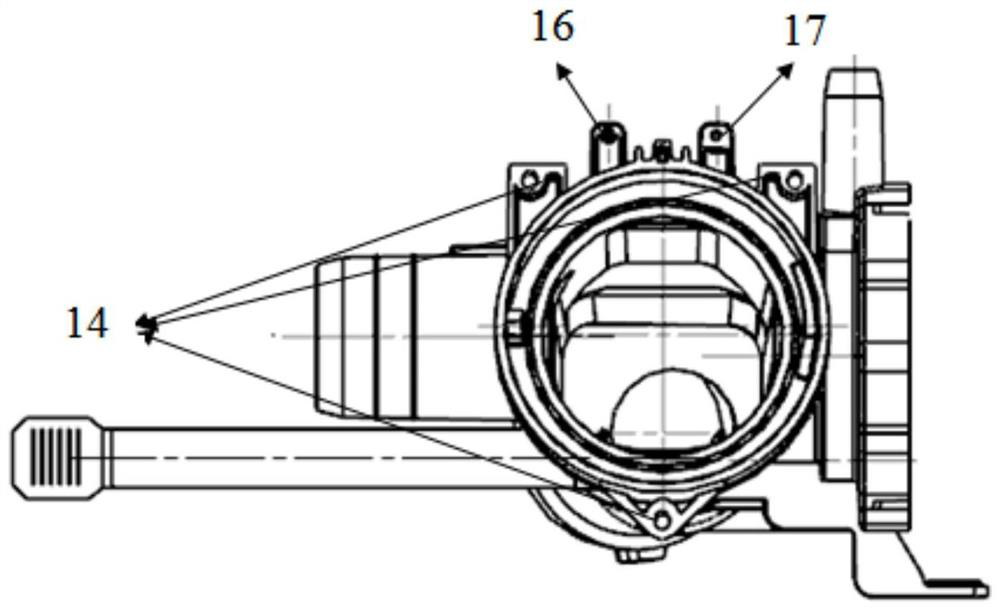

[0034] The drain valve body 1 provides the main structure of the drain valve assembly, and the self-induction screw cap assembly 2 is assembled on the drain valve body 1 through screw fitting. The drain valve body 1 is an integral structure with a water inlet 10, a water outlet 11, a circulating water outlet 12 and an emergency drain outlet 13. The drain valve body 1 is formed with a front fixing bracket 14 at the front and a rear fixing bracket at the rear. 15. The drain valve body 1 is fixed on the whole washing machine by screws by the front fixi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com