Fabricated building beam column steel structure connecting piece and construction method thereof

A technology for steel structures and connectors, applied in building components, building structures, buildings, etc., can solve the problems of labor-intensive, low assembly consistency, and achieve good installation consistency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

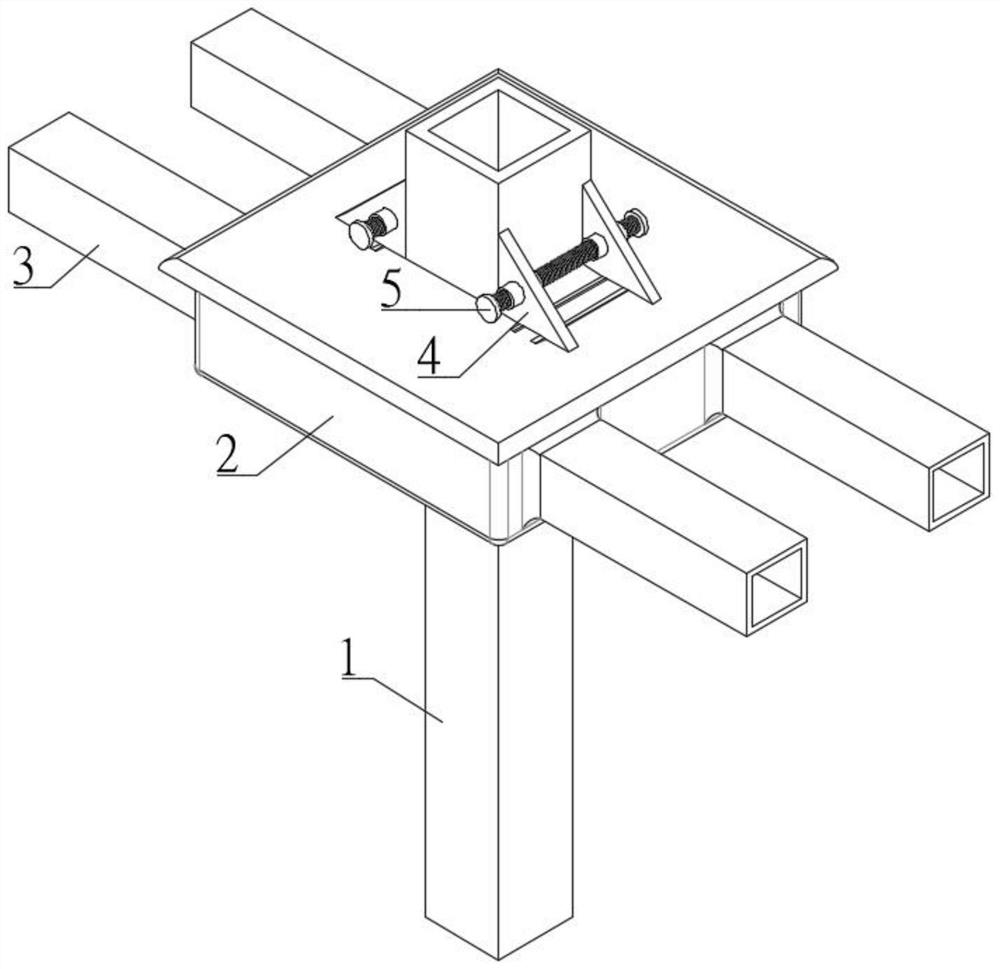

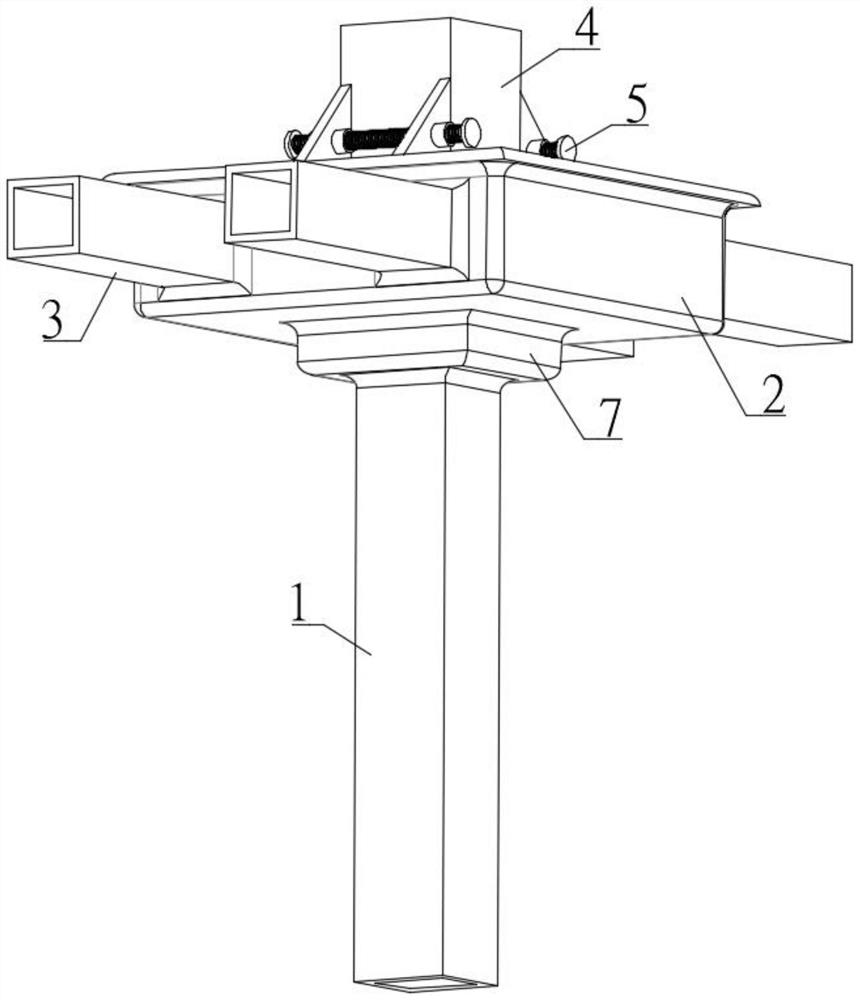

[0035] refer to Figure 1-6 , a prefabricated building beam-column steel structure connector, comprising a support beam 1, a beam 3, a steel structure connector 2, a sliding support angle steel 4, a beam locking component 5 and a safety protection component 6, as follows:

[0036] The steel structure connector 2 is arranged at the connection between the support beam 1 and the cross beam 3 , and the steel structure connector 2 is used for the support connection between the support beam 1 and the cross beam 3 . In this embodiment, the steel structure connector 2 adopts a hollow rectangular structure, and the steel structure connector 2 is provided with a cavity for accommodating the beam locking assembly 5 , for accommodating the through groove of the beam 3 .

[0037] In this embodiment, a reinforcing connecting piece 7 may be further arranged between the supporting beam 1 and the steel structure connecting piece 2 , refer to figure 2 As shown, the reinforcing connector 7 can...

Embodiment 2

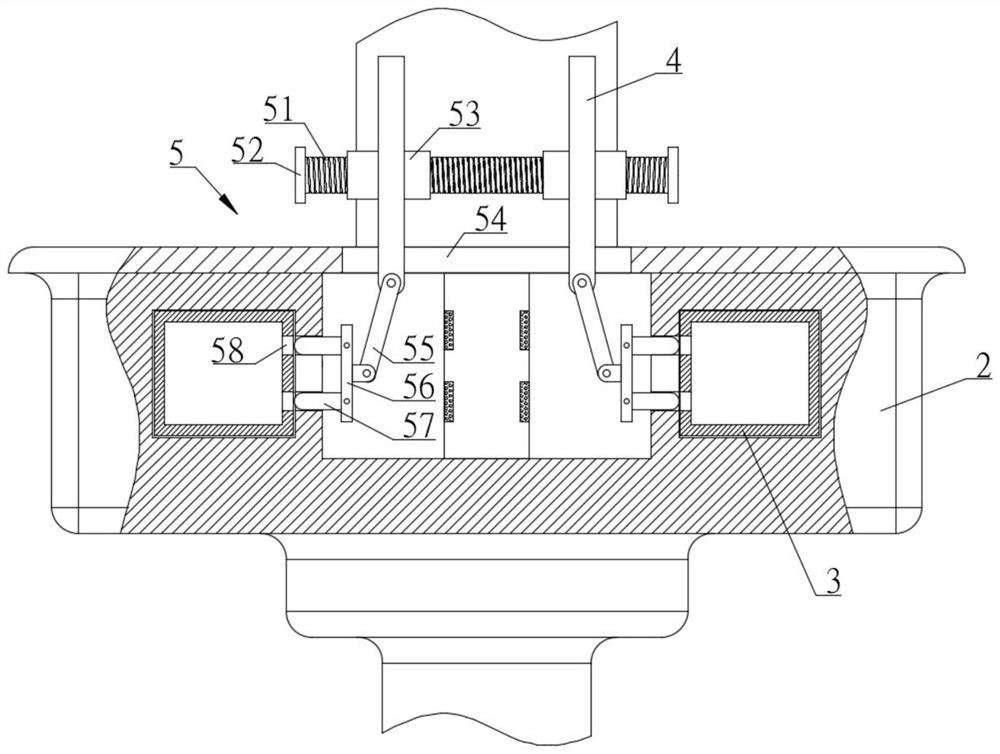

[0046] In this embodiment, the steel structure connector 2 is provided with a safety protection component 6 , and the safety protection component 6 includes a housing 61 , a fixed screen plate 62 , a moving screen plate 63 , a movable push rod 64 , a limit groove 65 , and a push-pull rod 66 , push plate 67, elastic member 68 and fire-fighting filling material 69, the specific connection method is:

[0047]The shell 61 is fixed on the inner wall of the steel structure connector 2, the fixed screen plate 62 is welded on the inner wall of the shell 61, the movable screen plate 63 is attached to the fixed screen plate 62, and the movable screen plate 63 and the shell 61 are arranged. The elastic member 68, under the action of the elastic member 68, the through holes of the moving screen plate 63 and the fixed screen plate 62 are staggered and closed. Similarly, when the elastic member 68 is compressed, the moving screen plate 63 is aligned and communicated with the through holes of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com