Mechanical and electrical integration limiting mechanism and limiting method

A limit mechanism, electromechanical technology, used in position/direction control, non-electric variable control, instruments, etc., can solve the problem of reducing the performance and reliability of mechanical limit, affecting the efficiency and service life of the drive mechanism, and the installation error of the travel switch. Loss of function and other problems, to achieve the effect of simple structure, uniform force balance, and ensure consistency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0042] Below in conjunction with accompanying drawing and specific embodiment the present invention is described in further detail:

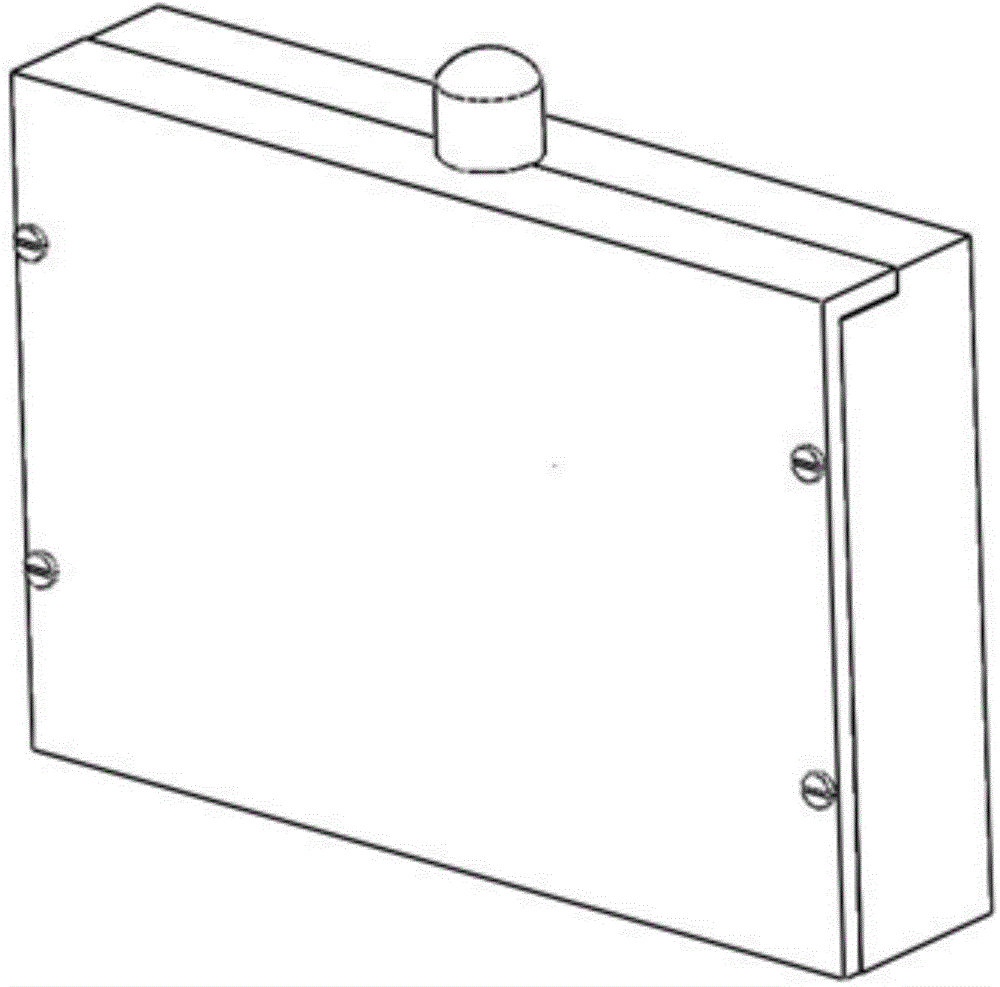

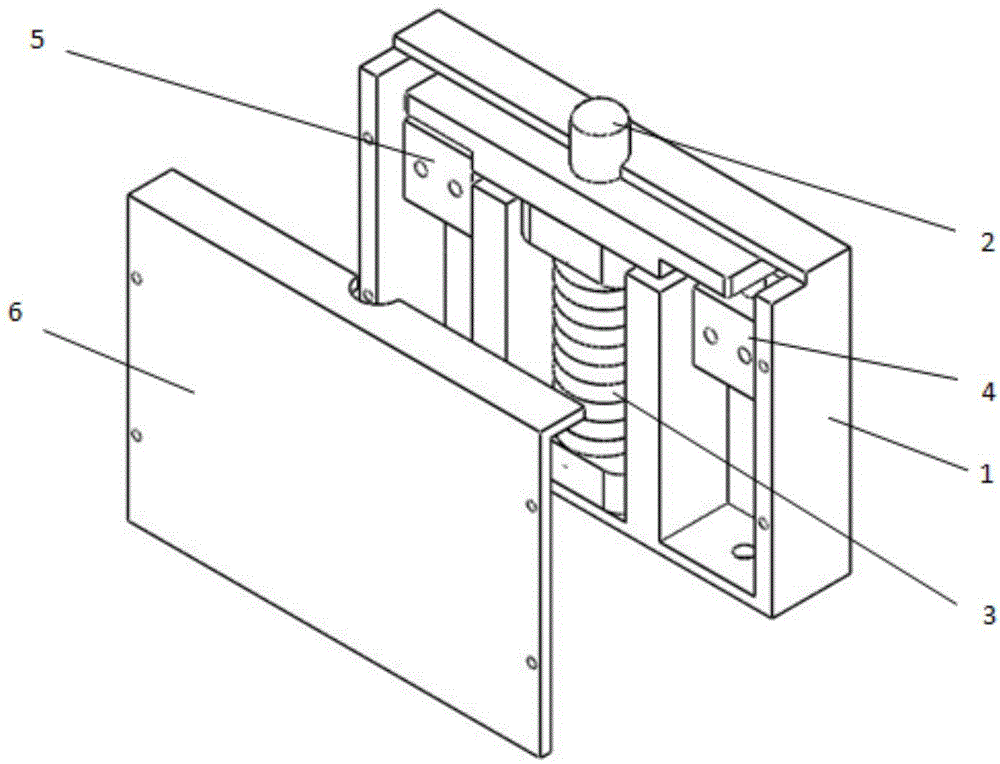

[0043] Such as figure 1 , 2 As shown in , 7, the present invention is a mechatronics limit mechanism for antennas in motion, which includes an integrated frame structure support 1, a guide mechanism 2, a damping spring 3, a travel switch M4, a travel switch N5, a shell Body cover plate 6, wiring through holes 30 and 31;

[0044] Such as Figure 7 As shown, the integrated frame structure bracket 1 includes a semicircular card slot 20, a stop block 24, a stop block 25, a cavity lower surface 22, a cavity rear surface 23, and a cavity end surface 40; the stop block 24, the stop block The block 25 is located on the lower surface 22 of the cavity of the integrated frame structure support 1 .

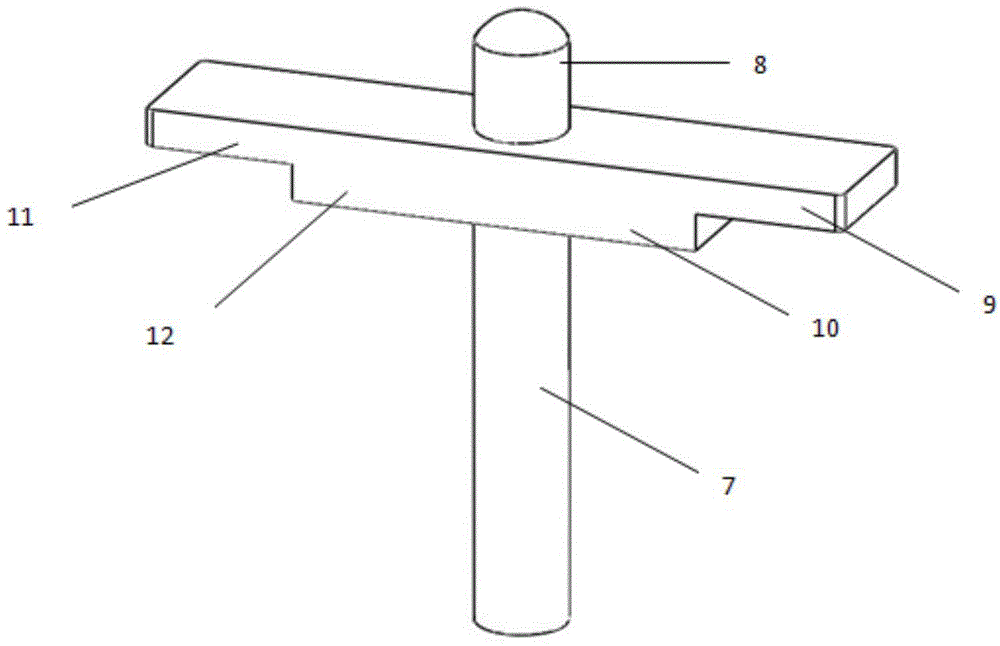

[0045] Such as image 3 As shown, the guide mechanism 2 includes a lower cylinder 7, an upper cylinder 8, a left forearm 9, a left rear arm 10, a right fore...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com