Auxiliary tooling and assembly and disassembly method for axial assembly and disassembly of precision parts of turbine main engine

A technology to assist tooling and parts, applied in metal processing, manufacturing tools, metal processing equipment, etc., can solve the problem of easy scratching of the spindle and precision parts, inability to lift the spindle to the exact position, extrusion of the lower half of the parts, etc. problems, to achieve the effect of good installation consistency, simple structure, and reduced installation difficulty

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0047] Embodiments of the present invention will be described in further detail below in conjunction with the accompanying drawings.

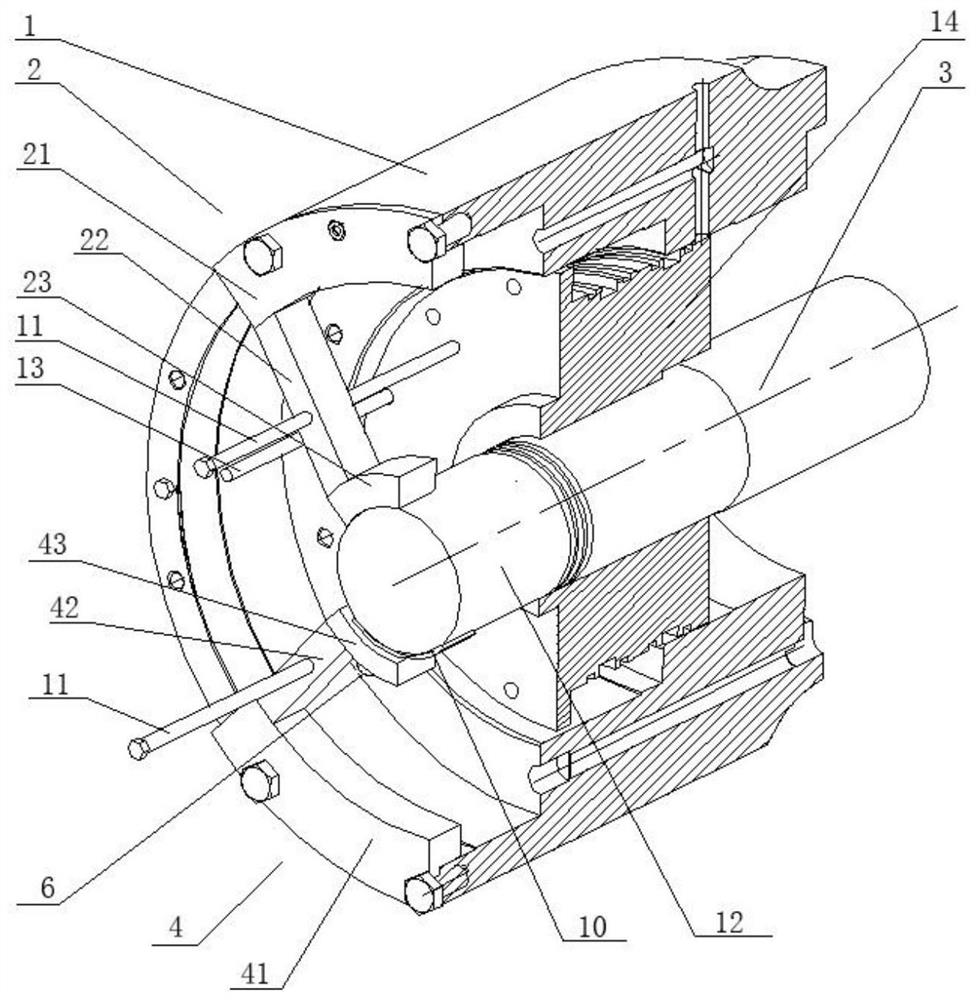

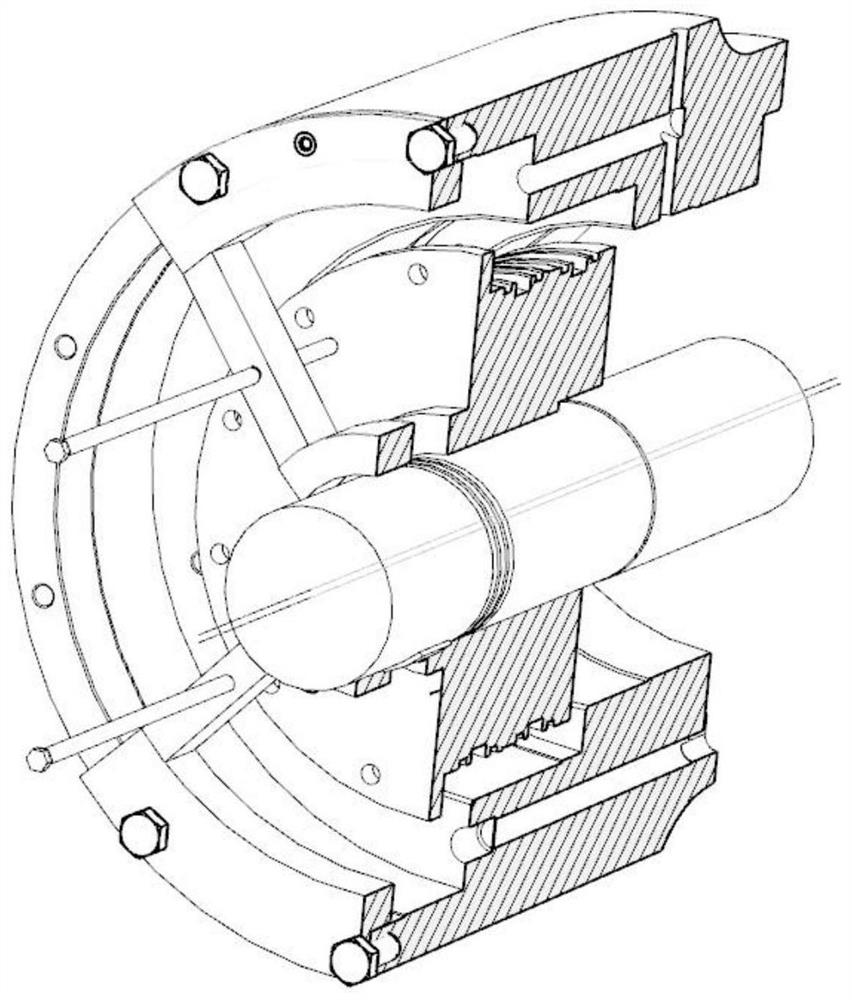

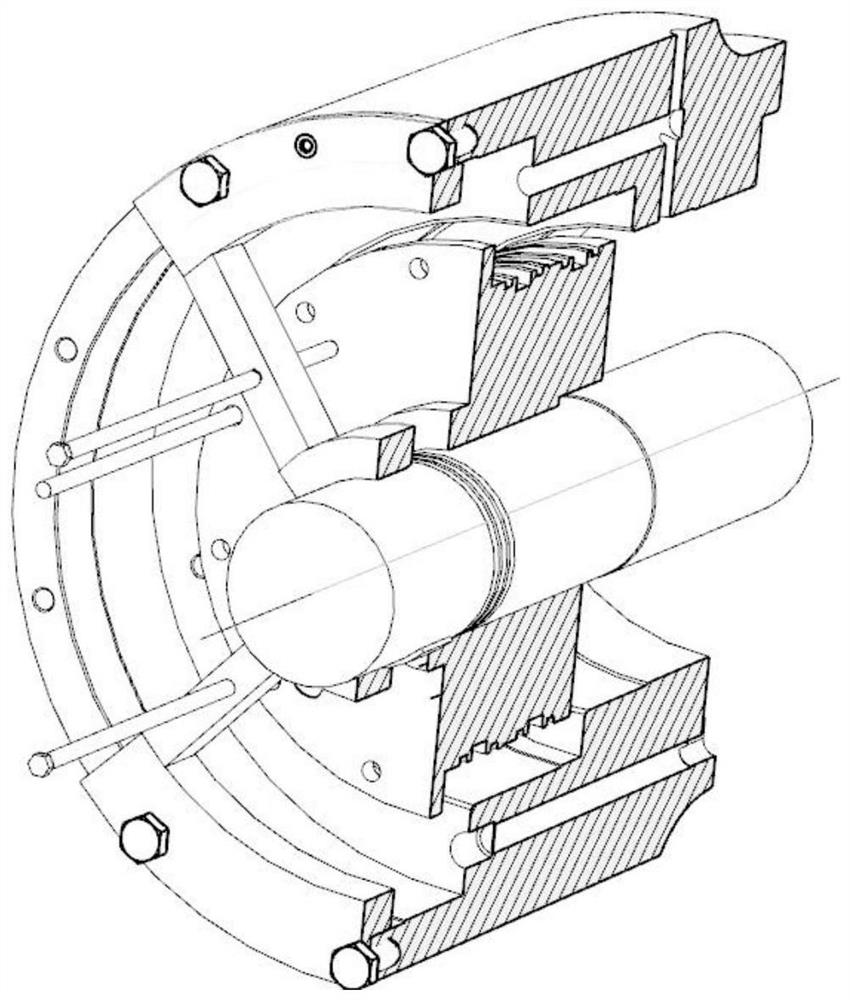

[0048] The positioning tool 2, the lifting tool 4 and the pushing tool in the auxiliary tooling of the present invention are symmetrically arranged on the end faces of both sides of the cylinder body,figure 1 What is shown is the auxiliary tooling installed on one side of the cylinder body, while the other side is omitted and not shown. figure 1 The A line in the figure is the axis of the cylinder body and the positioning tool, and the B line is the axis when the main shaft is not lifted.

[0049] see Figure 1-Figure 6 , an auxiliary tool for the axial assembly and disassembly of precision parts of a turbine main engine, including a positioning tool 2, the positioning tool 2 is arranged on the upper part of the end face of the cylinder body 1, and is fixedly connected with the end face of the cylinder body 1, and the positioning tool 2 It inc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com