Noose type non-uniform circumferential loading device and use method thereof

A loading device, non-uniform technology, applied in measuring devices, using stable tension/pressure to test material strength, reducing greenhouse gases, etc., can solve problems such as inaccurate test results, achieve flexible tension adjustment, prevent slippage, The effect of expanding the bearing area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0036] Below in conjunction with accompanying drawing, the present invention is described in further detail:

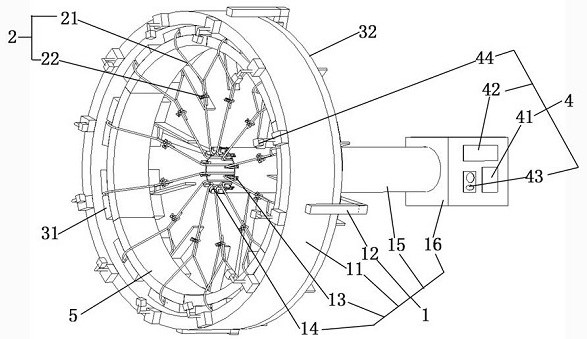

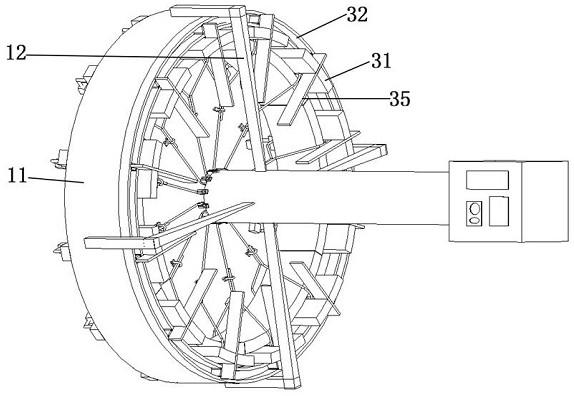

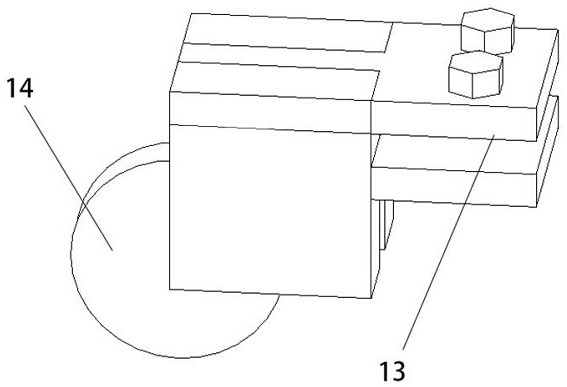

[0037] like figure 1 and figure 2 As shown, the present invention provides a noose type non-uniform hoop loading device. The device includes a casing 1 , a tension mechanism 2 , a force point fixing mechanism 3 , and a data detection and collection mechanism 4 . The shell 1 is connected with the force application point fixing mechanism 3 , and the force application point fixing mechanism 3 is connected with the tension mechanism 2 . The tension mechanism 2 is connected with the data detection and collection mechanism 4 , and the data detection and collection mechanism 4 is used to set the tension of the tension mechanism 2 and collect the deformation of the experimental sample 5 . The test sample 5 is set inside the force point fixing mechanism 3, and the force point fixing mechanism 3 is used to fix the position of the tension mechanism 2, and the force point fix...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com