Steel stranded wire mesh tensioning and fastening device for building structure reinforcement

A technology of building structure and steel strand, which is applied in the direction of building structure, construction, building maintenance, etc., can solve the problems of increased construction period and difficulty, low efficiency, inability to understand the strength and degree of tension, etc., to achieve Tensioning methods and functions are flexible and convenient

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

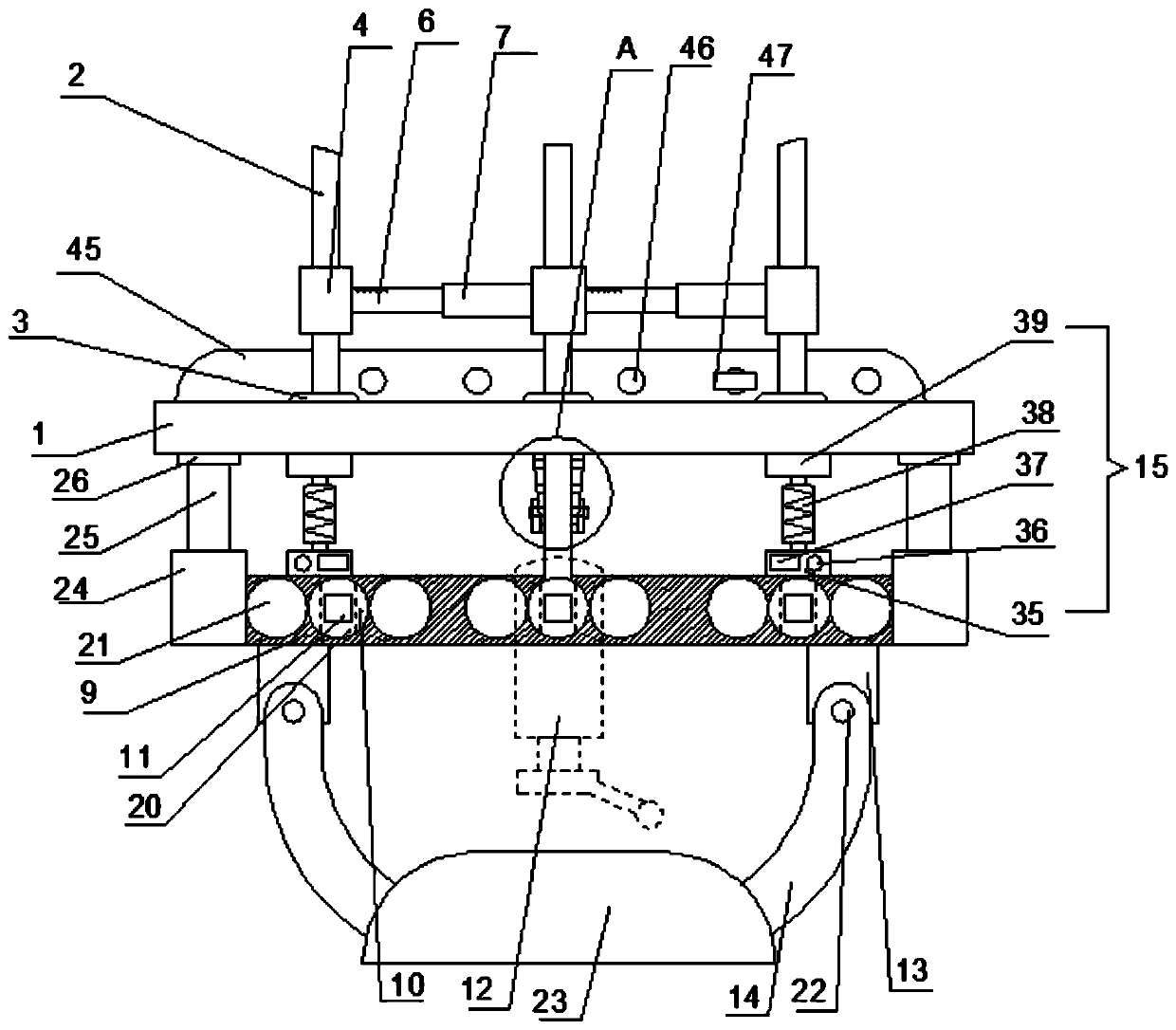

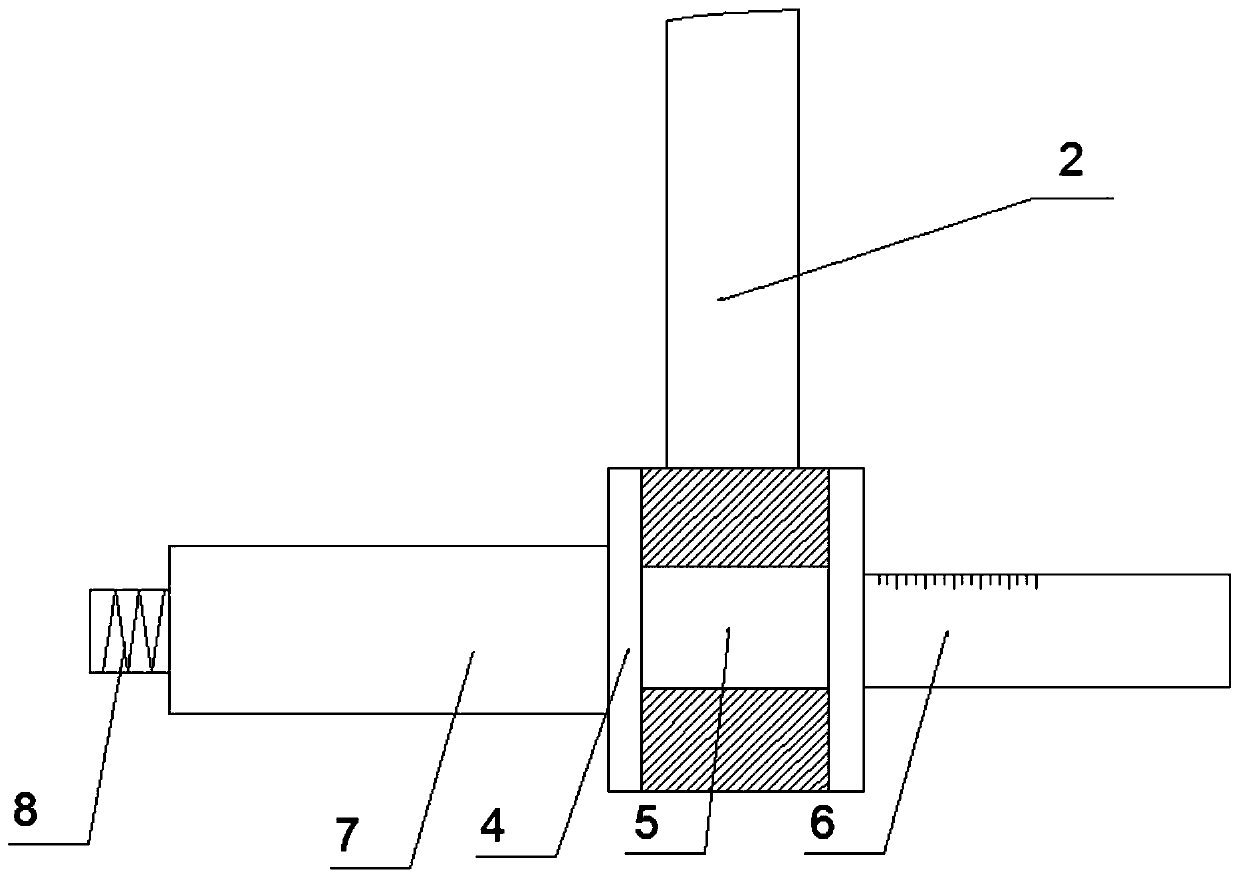

[0024] Such as Figure 1-6 As shown, the steel strand mesh tensioning and fastening device for building structure reinforcement according to the embodiment of the present invention includes a fixing frame 1, and the inside of the fixing frame 1 is provided with a number of steel strands 2 matched with it. A functional matching sleeve 3 is provided between the steel strand 2 and the fixing frame 1, and the steel strand 2 is provided with a number of uniformly distributed extension fixing strips 4, and the inside of the extension fixing strip 4 is provided with a number of Cooperating matching holes 5, one side of the extension fixing bar 4 is provided with a scale connecting rod 6 matched with it, and the outer wall of the scale connecting rod 6 is provided with a scale connecting sleeve matching with the extending fixing bar 4 7. The inside of the scale connection sleeve 7 is provided with a connection protection spring 8 that matches the scale connection rod 6, and the end of...

Embodiment 2

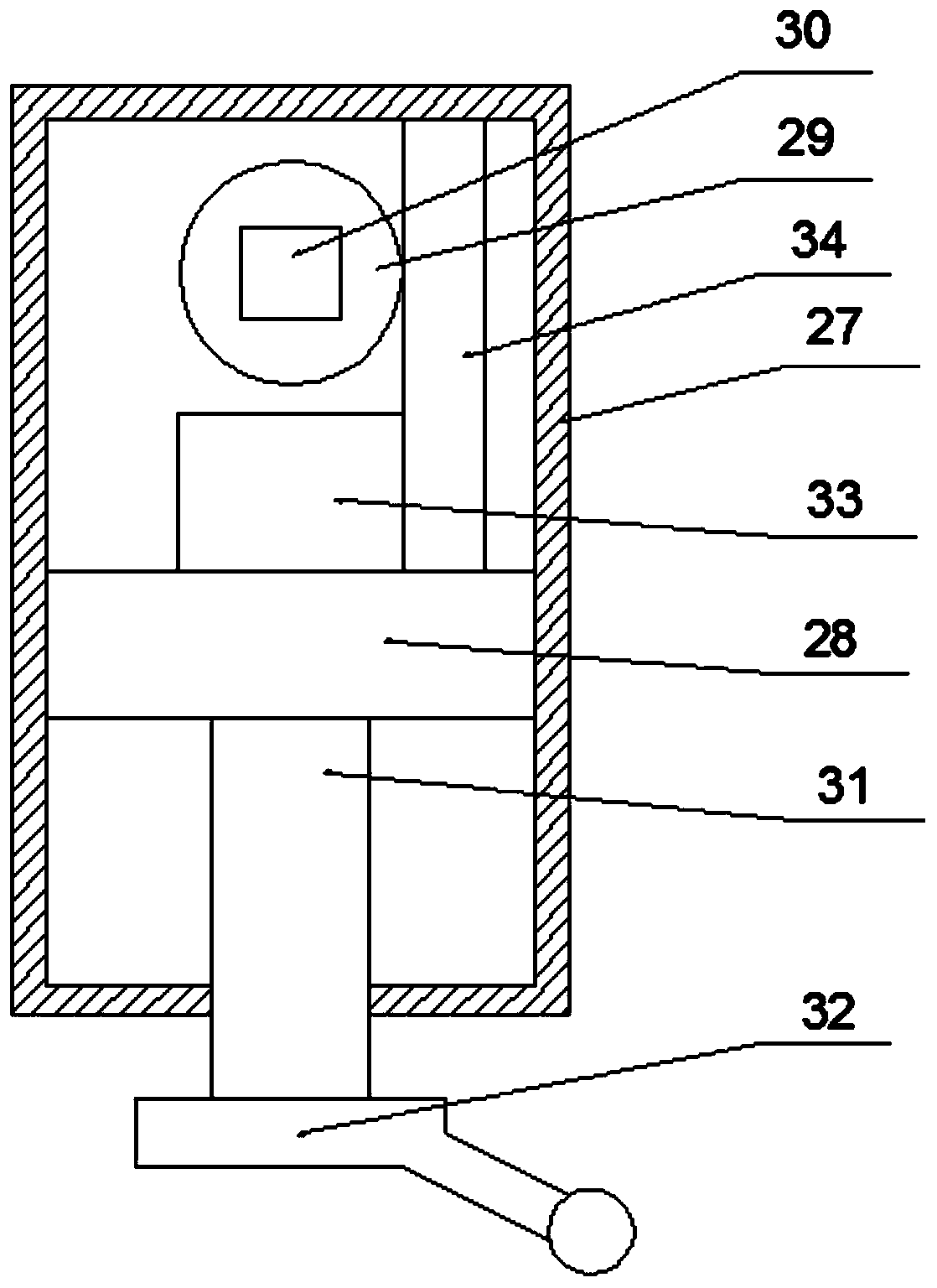

[0028] Such as Figure 1-6 As shown, the outer wall of the adjusting locking sleeve 16 is provided with an adjusting and fixing sleeve 18 matched with it, and both sides of the inside of the adjusting and fixing sleeve 18 are provided with adjusting and fixing pins 19 matched with the adjusting hole 17, The inside of the tensioning wheel 10 is provided with a steel strand fixing hole 20 matched with the steel strand 2, and both sides of the tensioning wheel 10 are provided with an anti-reverse gear 21 matched therewith, from It is not difficult to see from the above design that the existence of the anti-reverse gear 21 can prevent the rebound of the structure and force due to the approach of the tension limit during the tensioning process of the steel strand 2, and the continuous adjustment of the fixed sleeve 18 Tightening at the adjusting locking sleeve 16 can make the adjusting locking sleeve 16 firmly fix the steel strand 2, which can further prevent shrinkage and springba...

Embodiment 3

[0030] Such as Figure 1-6 As shown, a pull shaft 22 is provided between the pull rope 14 and the pull frame 13, and the end of the pull rope 14 away from the pull frame 13 is provided with a manual twist handle 23 matched therewith. A connecting plate 26 is provided between the rod 25 and the fixed frame 1. It is not difficult to see from the above design that the tension frame 9 can be manually pulled and tensioned by pulling the rope 14 by manually twisting the handle 23 to ensure flexibility. At the same time, it can play the effect of auxiliary backup function.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com