Pressure relief method of pressure relief device of switch cabinet

一种泄压装置、开关柜的技术,应用在开关装置的设置、开关装置、变电站/开关装置的冷却/通风等方向,能够解决浪费资源、开关柜炸裂、增加泄压成本等问题,达到节约泄压成本、减小泄压负担、减少浪费的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

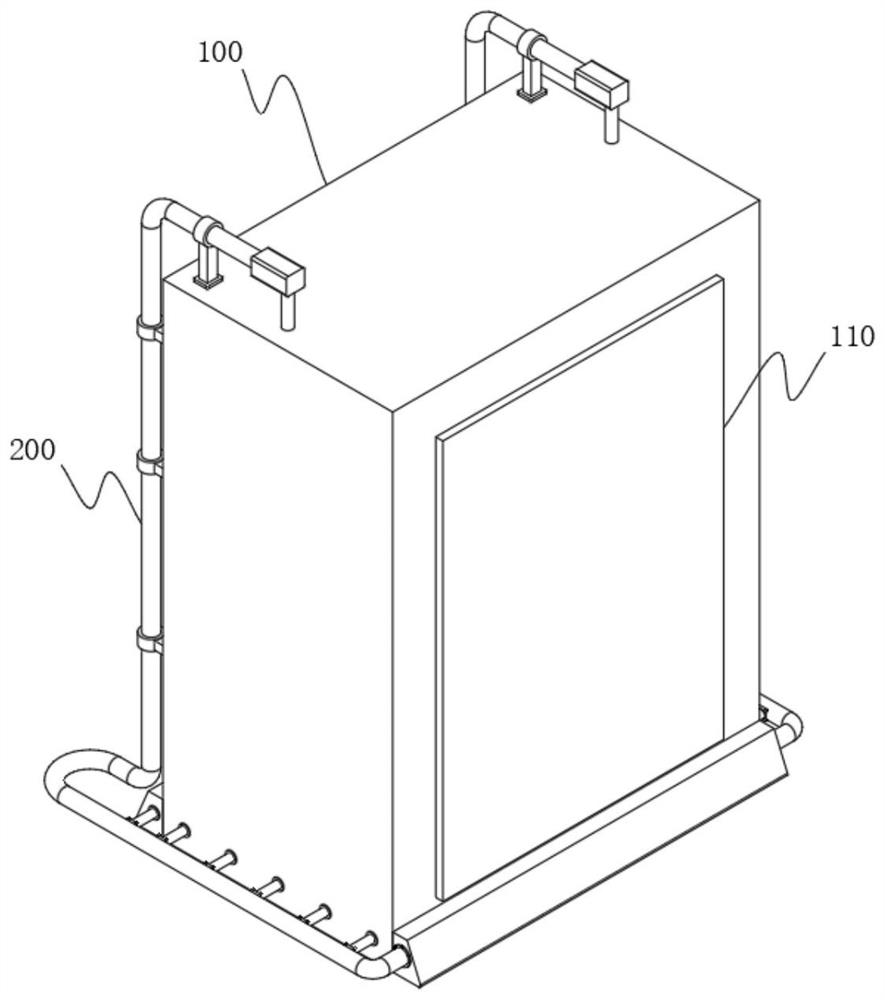

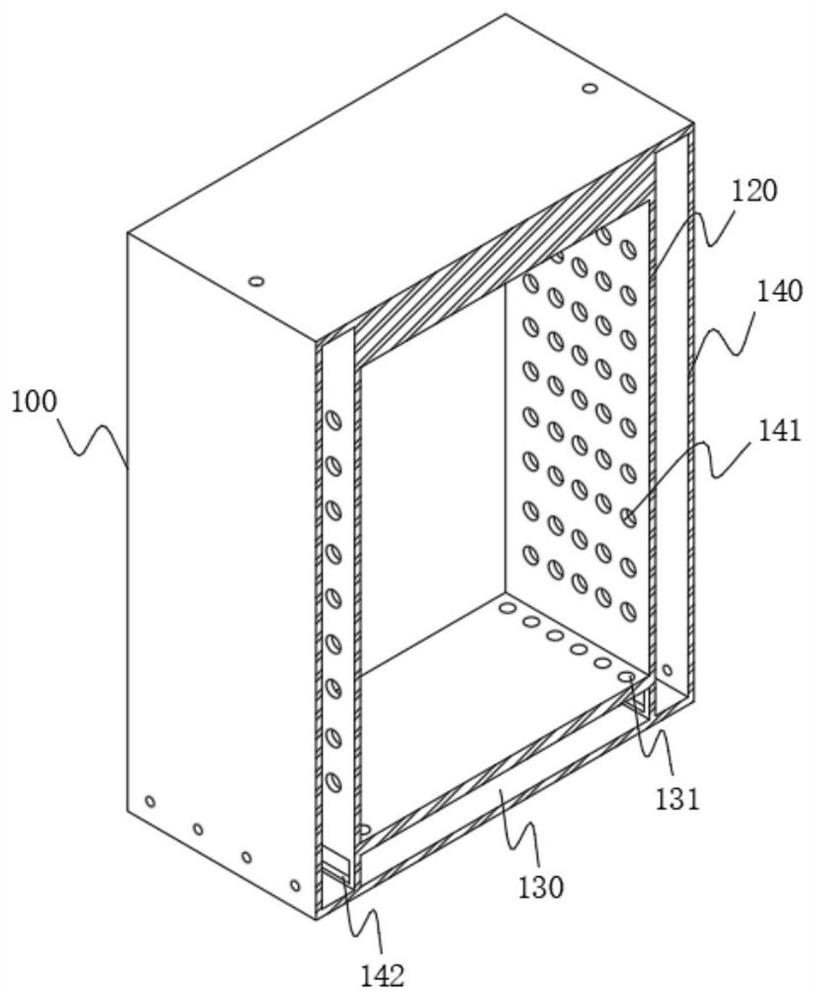

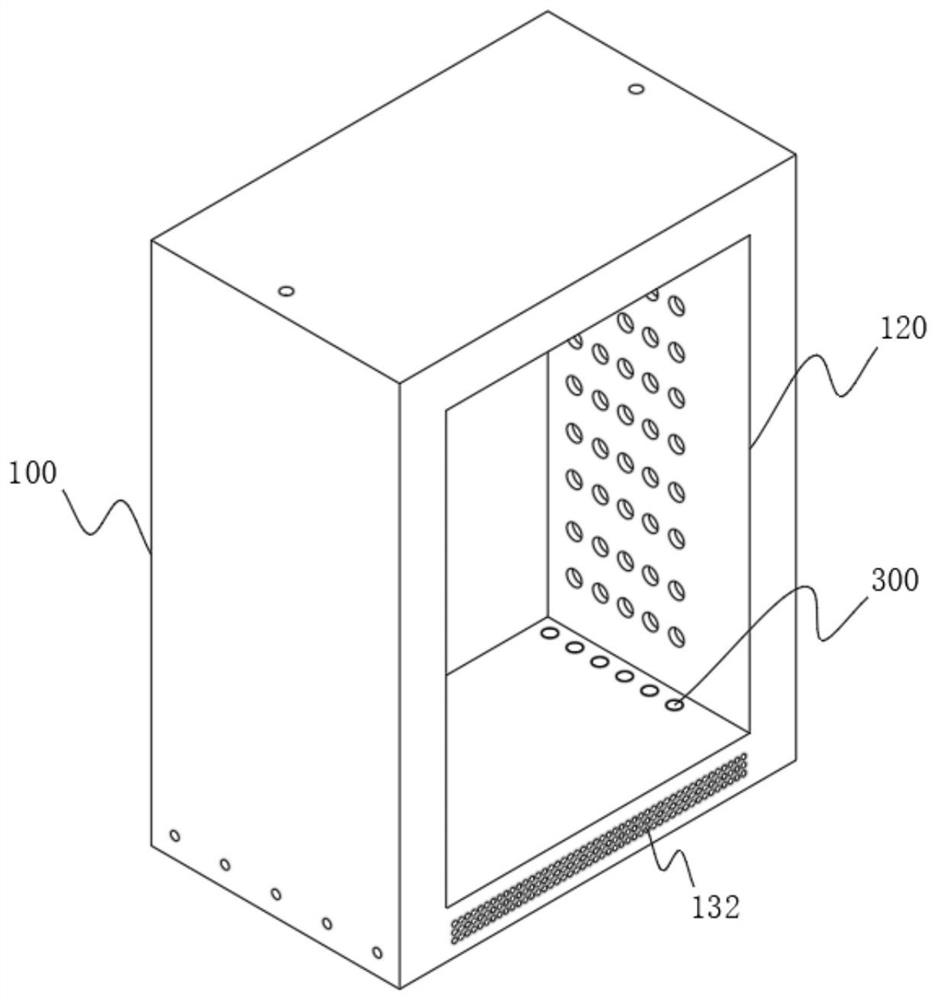

[0055] see Figure 1-Figure 13 As shown, one of the purposes of this embodiment is to provide a safe pressure relief device for a switchgear, including a cabinet body 100, a backflow device 200, and a pressure relief device 300 disposed inside the cabinet body 100. The cabinet body 100 includes a cavity 120 The left and right sides of the cavity 120 are provided with side pressure relief chambers 140, the position between the bottoms of the two side pressure relief chambers 140 is provided with a bottom pressure relief chamber 130, and the side pressure relief chambers 140 and the cavity 120 are arranged in a rectangular shape. There are a plurality of fixed pressure relief holes 141, a chute 142 is provided between the bottom pressure relief chamber 130 and the side pressure relief chamber 140, and a plurality of pressure relief grooves are provided on the side of the top of the bottom pressure relief chamber 130 close to the side pressure relief chamber 140 131. The front si...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com