Stator, motor and method for winding stator teeth of stator of brushless motor

A technology of stator teeth and stator, applied in the field of stator

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

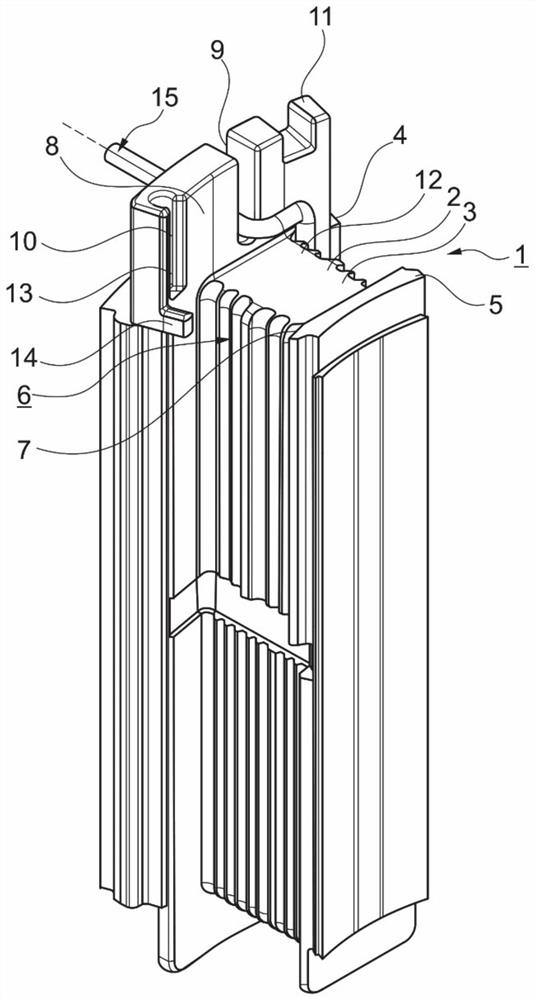

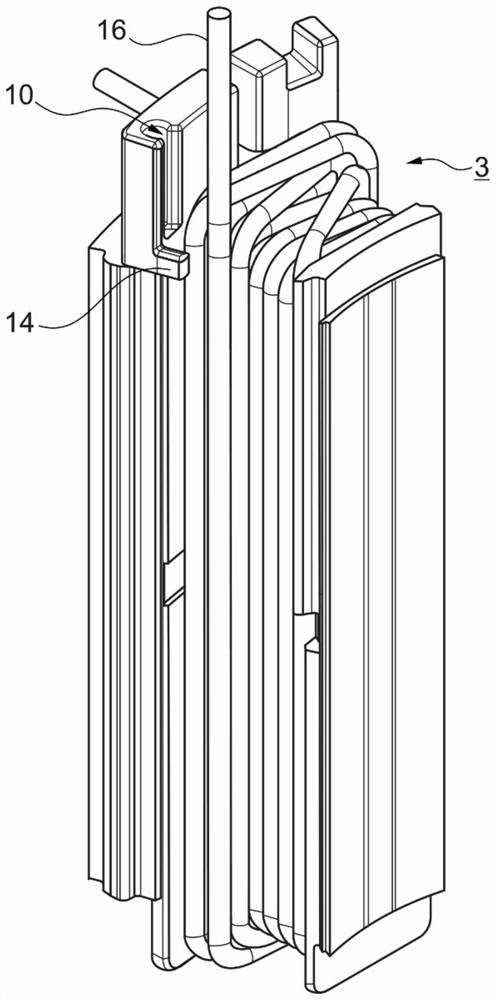

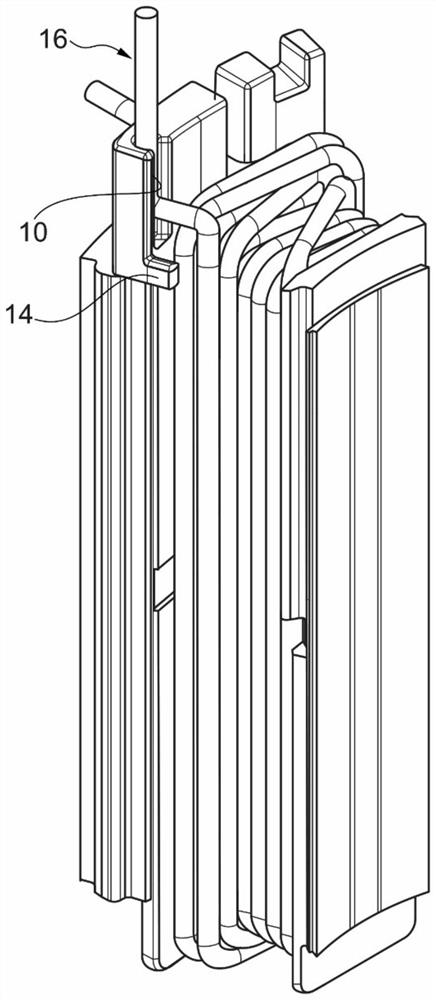

[0031] figure 1 The stator teeth 1 are shown with an insulator 2 which insulates the windings (not shown in the figures) from the stator teeth 1 . Each stator tooth 1 has an elongated tooth body 3 and a tooth root 4 adjoining the tooth body 3 at a radial end, and a tooth tip 5 adjoining the tooth body 3 at the other end. The tooth roots 4 are wider than the tooth tips 5 in the circumferential direction relative to the longitudinal axis of the stator, and the tooth roots 4 are located radially outside the tooth tips 5 . The insulator 2 surrounds parts of the tooth body 3 , the tooth tip 5 and the tooth root 4 . A winding chamber 6 in which the insulator 2 is wound in each case by a winding wire (not shown in the figures). The winding chamber 6 has a winding space which is bounded on the inside by an inner flange 7 and on the outside by an outer flange 8 in the radial direction relative to the longitudinal axis of the stator. The outer flange 8 has a slot-shaped first recess ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com