LCD Panel cleaning method and cleaning equipment

A technology for cleaning equipment and cleaning agents, applied in the field of LCDPanel cleaning, can solve the problems of poor emulsification effect of cleaning agent B, shorten the service life of cleaning agent B, etc., and achieve the effects of improving service life, reducing loss and rapid separation

Active Publication Date: 2022-05-31

惠州市飞世尔实业有限公司

View PDF13 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0004]

In view of the related technologies mentioned above, after the LCD Panel is cleaned by cleaning agent A, cleaning agent A will remain on the surface and slits of the LCD Panel, and cleaning agent A will be carried to cleaning agent B as the cleaning progresses. Therefore, the emulsification effect of cleaning agent B is getting worse and worse, which will lead to the defect of shortening the service life of cleaning agent B

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

The invention relates to an LCD Panel cleaning method. The LCD Panel cleaning method comprises the following steps that S1, an LCD is soaked and cleaned with a cleaning agent A; s2, the LCD is soaked and cleaned with clear water; s3, soaking and cleaning the LCD by using a cleaning agent B; s4, cleaning the LCD with clear water; and S5, carrying out drying treatment on the LCD. The cleaning agent has the effect of prolonging the service life of the cleaning agent B.

Description

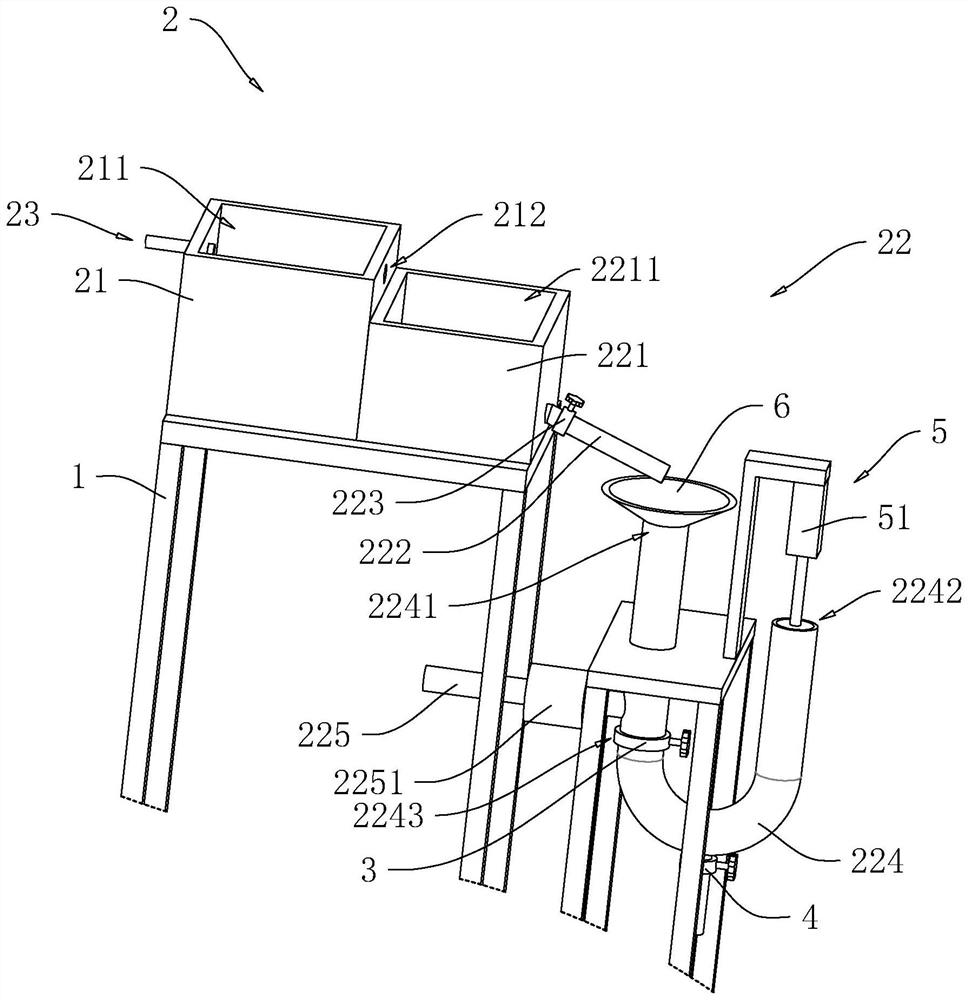

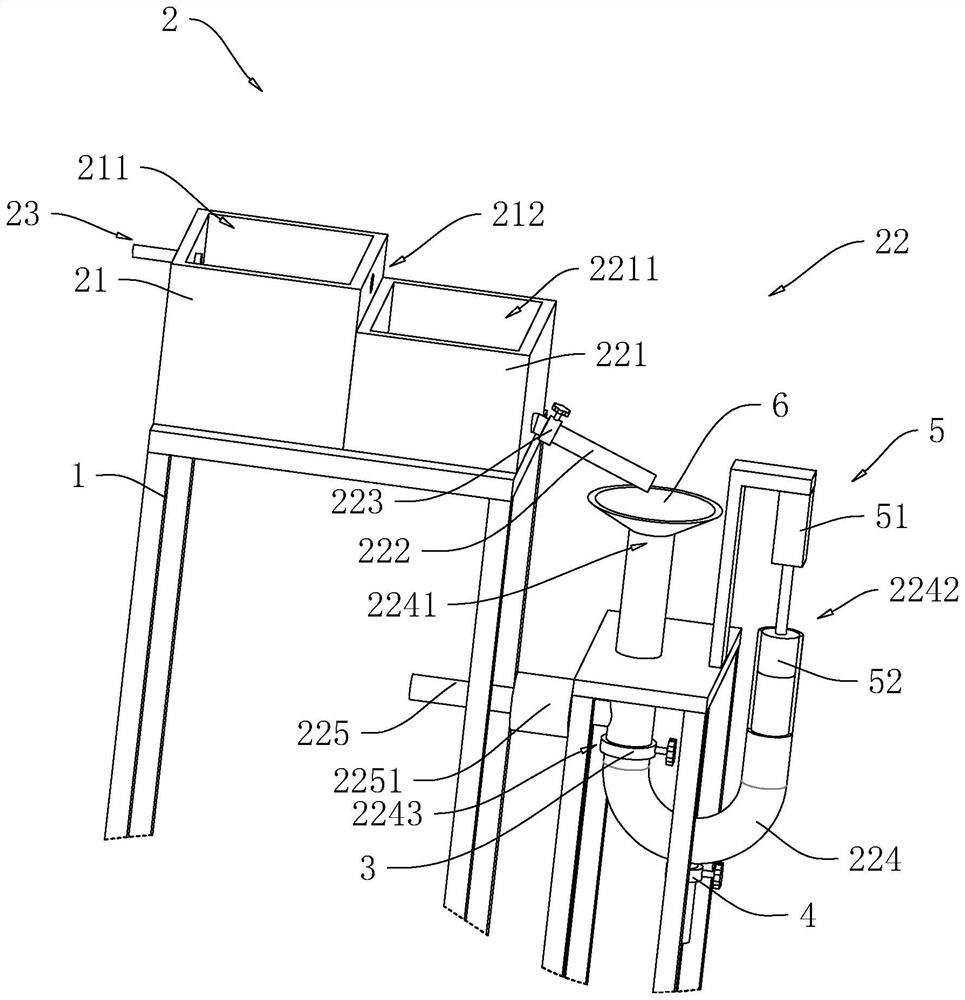

A kind of LCD Panel cleaning method and cleaning equipment technical field The application relates to the field of LCD Panel cleaning, especially relate to a kind of LCD Panel cleaning method and cleaning device ready. Background technique LCD Panel generally refers to a liquid crystal panel, which determines the brightness, contrast, color, visual The material of the angle, and the quality and technology of the liquid crystal panel are related to the overall performance of the liquid crystal display. After it is done, it is necessary to perfuse the relevant liquid crystal, then seal it with UV curing glue, and finally use the relevant cleaning agent to clean the LCD surface and the narrow space. Clean the liquid crystal in the seam, fingerprints on the surface, glass powder, dust and other dirt. [0003] In the related art, the LCD Panel cleaning method is to first use the cleaning agent A to clean the liquid crystal, fingerprints, etc. on the LCD Panel. Remove th...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): B08B3/04B08B3/08B08B3/12B08B13/00

CPCB08B3/048B08B3/08B08B3/12B08B13/00

Inventor 钟平洪刘呈贵陈才旺许华兵

Owner 惠州市飞世尔实业有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com