Cutting equipment capable of recycling cutting fluid

A technology of cutting equipment and cutting fluid, applied in the field of machine tool parts processing, can solve the problems of effective isolation of cutting chips and cutting fluid, and inability to filter and recycle the cutting chips, so as to reduce processing costs, flexibly isolate and recycle collection, and reduce waste. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

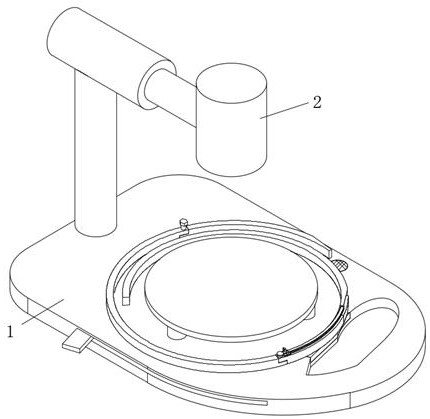

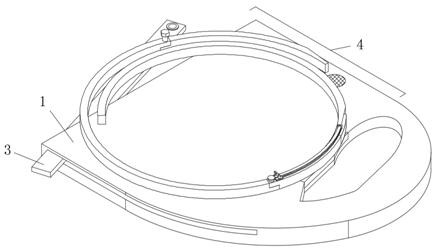

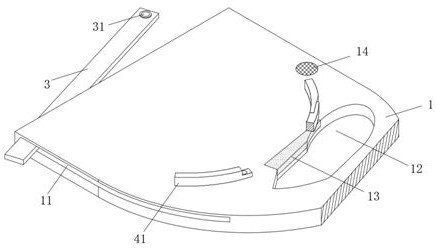

[0030] see Figure 1-7 , the present invention provides a technical solution: a cutting device for circulating cutting fluid, including a base plate 1, a cutting device 2 for cutting a workpiece is installed on the top of the base plate 1, and the middle part of the top surface of the base plate 1 is installed There is an operation bench, and the operation bench is used to limit and fix the workpiece. The inside of the base plate 1 is equipped with a magnetic block swing bar 3, and the middle part of the top of the base plate 1 is installed with a loop assembly 4. The top surface of the base plate 1 is close to the side. A pyramid drain plate 13 is installed at the side position, and the pyramid drain plate 13 is used for secondary filtration and recovery of the cutting fluid; the loopback assembly 4 includes a first arc plate 41 for surrounding the operating platform, and one end of the first arc plate 41 An adsorption component 43 is connected, and the adsorption component 4...

Embodiment 2

[0037] Such as Figure 1-7 As shown, the present invention provides a technical solution: a cutting device for circulating cutting fluid, including a base plate 1, a cutting device 2 for cutting a workpiece is installed on the top of the base plate 1, and the top surface of the base plate 1 is An operating bench is installed in the middle, and the operating bench is used to limit and fix the workpiece. The magnetic block swing bar 3 is installed inside the base plate 1, and the loop assembly 4 is installed in the middle of the top of the base plate 1. The top surface of the base plate 1 A pyramid drain plate 13 is installed near the side, and the pyramid drain plate 13 is used for secondary filtration and recovery of cutting fluid; the loopback assembly 4 includes a first arc plate 41 for surrounding the operating platform, and the first arc plate 41 One end of the suction assembly 43 is connected to the adsorption assembly 43, which is used to absorb and gather cutting chips....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com