Novel cutting equipment for building material manufacturing

A construction material and cutting technology, which is applied in the direction of manufacturing tools, metal processing equipment, grinding/polishing equipment, etc., can solve the problems of injury to operators, inconvenient collection of powder chips, loss of sealing and covering effect of plastic sheets, etc., to achieve relief The effect of squeezing pain

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

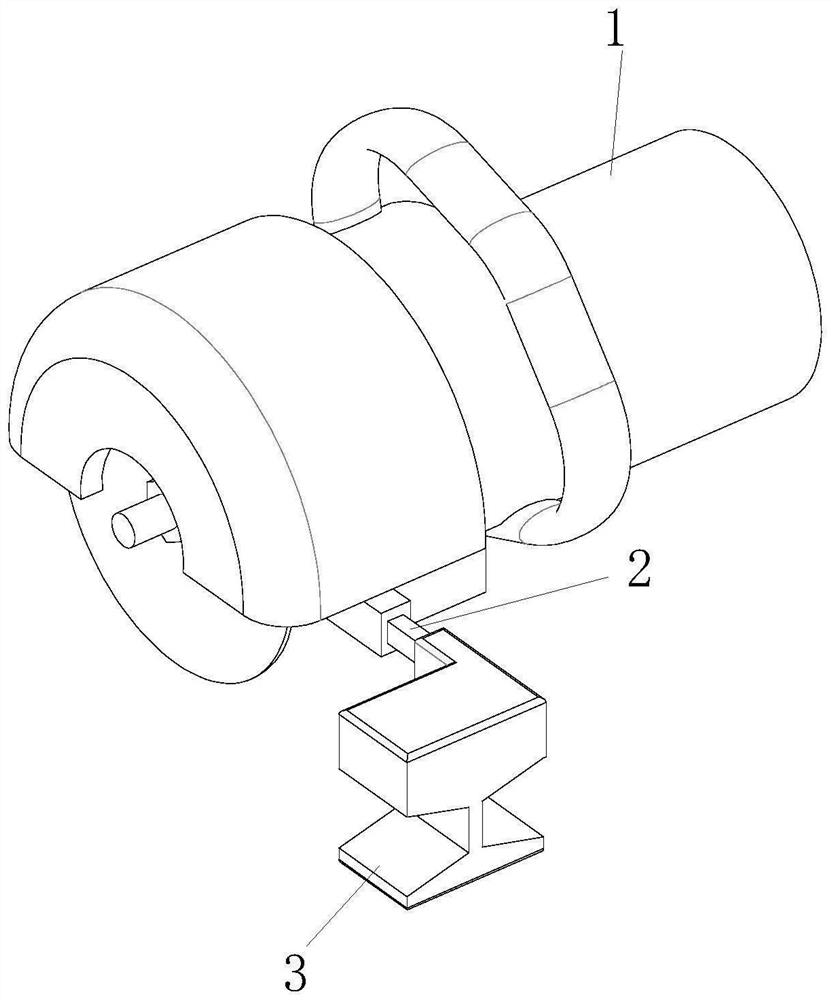

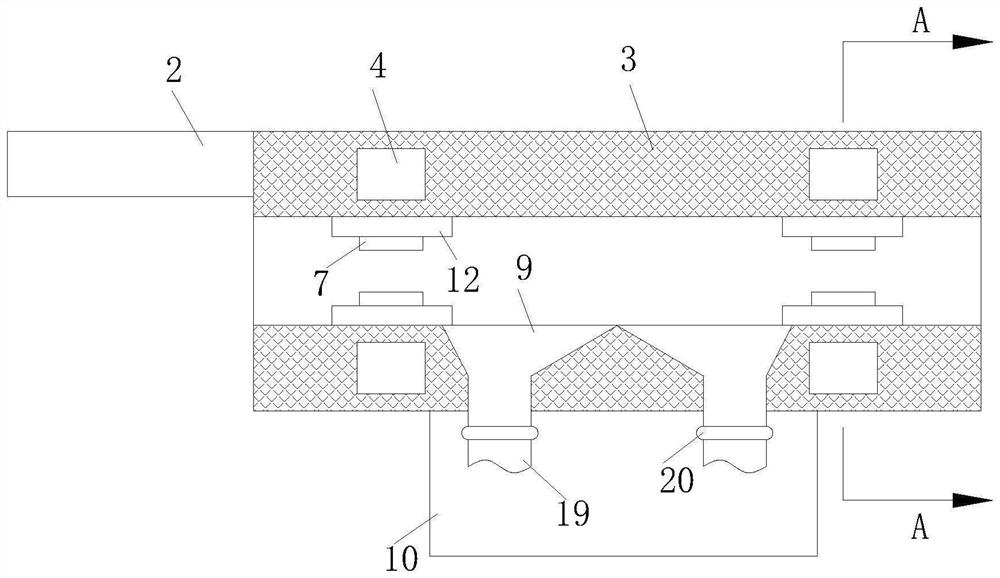

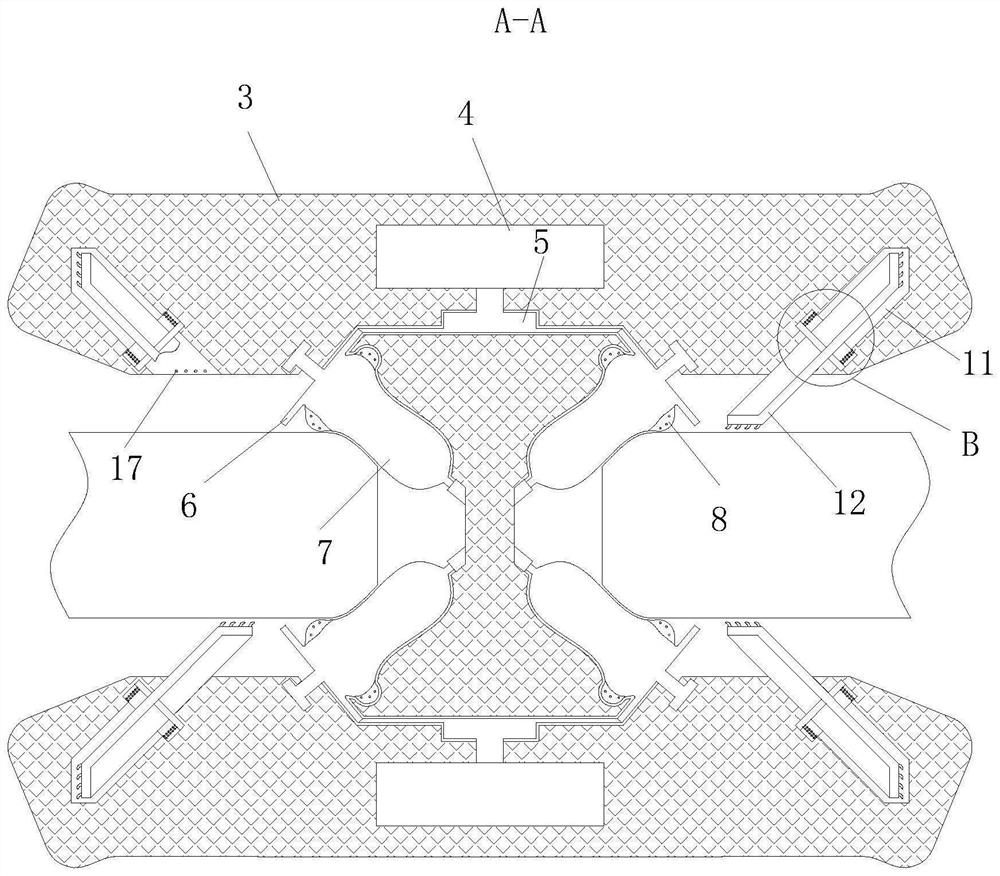

[0032] refer to Figure 1-3 , a new type of cutting equipment for the manufacture of building materials, including a cutting machine 1, the rear side of the electric saw blade of the cutting machine 1 is provided with a grinding assembly; the grinding assembly includes a connecting rod 2, a connecting block 3 and a grinding unit; one end of the connecting rod 2 is fixed on the casing of the cutting machine 1, and the other end of the connecting rod 2 is fixed on the end face of the connecting block 3; the cross-section of the connecting block 3 is in the shape of "I", A plurality of grinding units are installed in the two concave parts of the connecting block 3;

[0033]The grinding unit includes a motor 4, a driving gear 5, a driven gear 6 and a grinding wheel 7; the upper end and the lower end of the connecting block 3 are internally installed with a motor 4, the output ends of the two motors 4 are arranged oppositely, and the output end of the motor 4 The driving gear 5 is...

Embodiment 2

[0043] refer to Figure 7 , Comparative Example 1, as another embodiment of the present invention, wherein the openings on both sides of the connecting block 3 are wide-mouthed; 3 in the concave part.

[0044] Working principle: the cutting machine 1 inserts the connecting block 3 into the cutting seam from one side of the plate during the cutting process along the surface of the plate, and the cutting and breaking surface of the plate is placed in the concave part of the connecting block 3. The motor 4 is driven, and the motor 4 drives the driven gear 6 to rotate through the driving gear 5, and the driven gear 6 drives the grinding wheel 7 to rotate. The round shape reduces the possibility that some plastic film building materials will be scratched and torn by the edges and corners of the burr after cutting, and at the same time reduce the possibility that the sharp burr will scratch the hands of the workers. After cutting, it can be put into use, reducing the trouble of su...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com