Subway track plate fine adjustment device, system and method

A track slab and slab fine-tuning technology, which is applied in the direction of track, track laying, track maintenance, etc., to achieve the effects of reducing labor intensity, saving time, and saving interval time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

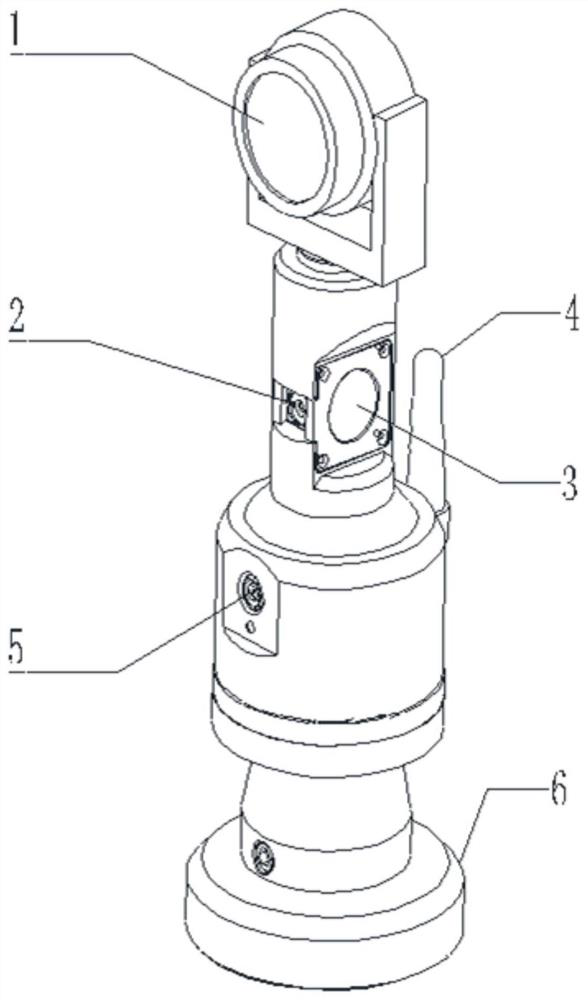

[0038] Embodiment 1: the structure of subway track slab fine adjustment device is as follows figure 1 , the reflective prism 1 is installed on the upper cylinder, the upper cylinder is installed on the middle cylinder, the middle cylinder is installed on the base 6 through the lower cylinder, and the laser plummet 2 is installed in the upper cylinder. Adjust the angle of the laser plummet 2 by adjusting the knob 3 and the worm mechanism.

[0039] Reflecting prism 1 is hinged on the fork-shaped support, and the lower end of the fork-shaped support is rotatably installed at the end of the worm. The reflective prism 1 can rotate on the vertical plane, and the fork support can rotate on the horizontal plane.

[0040] A laser plummet 2 is installed on the upper column, a laser generator, an inclination sensor, a controller and a power supply are installed in the middle column, and an antenna connected to the controller is arranged on the side of the middle column.

[0041] Inclin...

Embodiment 2

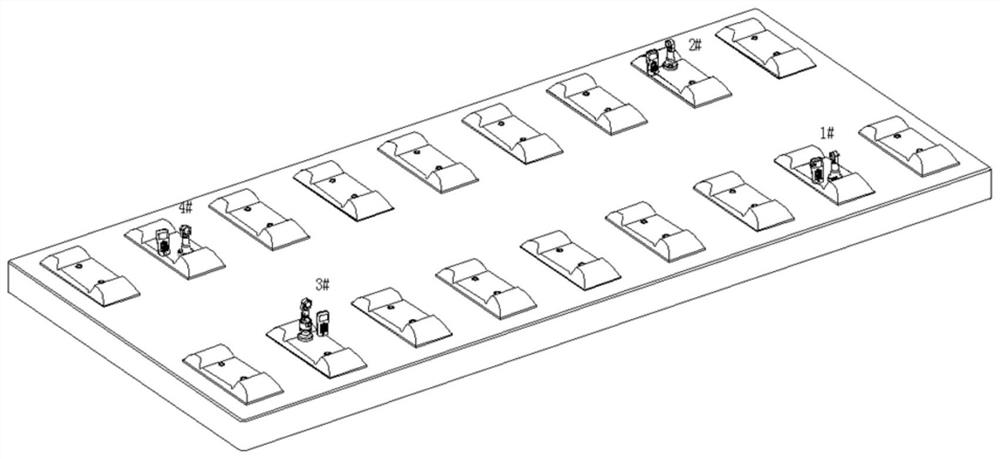

[0045]Embodiment 2: This embodiment is a system for the fine adjustment of subway track slabs. The system includes a main tooling, 3 auxiliary toolings, a control terminal, a total station and four adjustment indicators. Realize the data transmission between each component, install the fine-tuning software, the fine-tuning software controls the total station to measure the reflective prism 1 of the main tooling and read the inclination data, calculate the adjustment amount of the 4 stations and send it to the corresponding adjustment amount display .

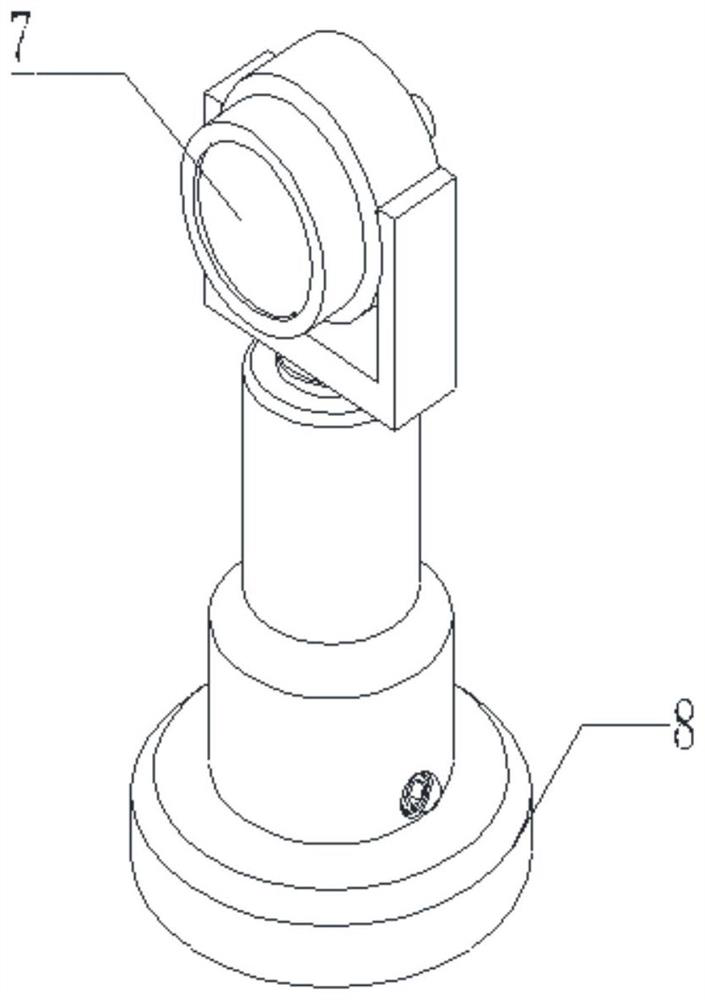

[0046] The subway track slab fine adjustment device in Example 1 is used as the main tooling, and the structure of the three auxiliary tools includes a secondary reflective prism 7 and a secondary base 8. The secondary reflective prism 7 is hinged on the fork-shaped bracket, and the lower end of the fork-shaped bracket is rotatable. is installed on the column, and the column is installed on the auxiliary base 8, and the main too...

Embodiment 3

[0056] A fine-tuning system for a subway track slab includes a control terminal, fine-tuning software, 4 measuring fixtures, 4 reflective prisms, and 4 adjustment-value displays, wherein No. 3 measuring fixture has a built-in inclination sensor.

[0057] A CF radio station is designed on the control terminal, and a data transmission radio station is also designed on the total station end. The data transmission radio station, the external battery and the total station are connected through a Y-shaped data cable. Each display also contains a radio station. The whole set Data communication between measurement systems is done via radio.

[0058] The measuring tooling is designed with different front and rear heights, so that more track plates can be fine-tuned when the total station is erected at one station.

[0059] The fine-tuning software is designed with a variety of measurement modes. In addition to the traditional measurement modes "measure 1-2", "measure 3-4", "four-corner...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com