Arm type centrifugal machine high-centrifugal-force environment high-pressure liquid conveying system

A conveying system and centrifuge technology, applied in pipeline systems, gas/liquid distribution and storage, mechanical equipment, etc., can solve problems such as non-tensile strength, seal failure, fracture, etc. added effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The specific embodiments of the present invention will be described in further detail below in conjunction with the accompanying drawings.

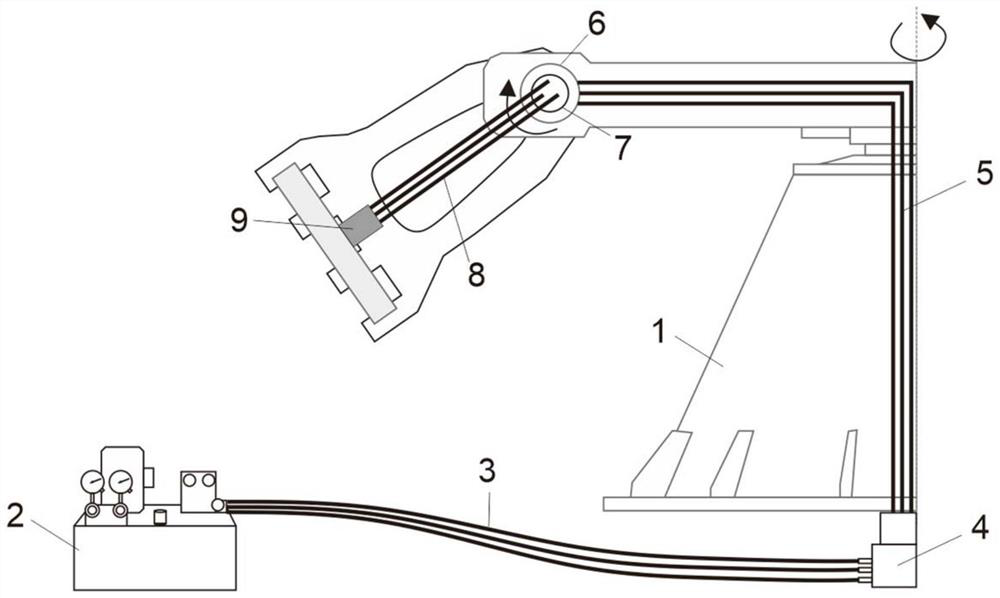

[0027] Such as figure 1 As shown, the present invention provides an arm centrifuge high centrifugal force environment liquid delivery system, which can meet the safe delivery of high pressure oil in the centrifuge basket under the condition of high centrifugal force exceeding 200g. Including centrifuge host 1, ground liquid source 2, ground delivery pipeline 3, centrifuge bottom rotary joint 4, centrifuge rotary arm delivery pipeline 5, rotary arm-basket pin shaft 6, hanging basket rotary joint 7, hanging basket transportation The pipeline 8 and the hanging basket pipeline are connected to the outlet 9.

[0028] The ground liquid source 2 includes a hydraulic pressure source, a water source, etc., and is connected to the stator end of the rotary joint 4 at the bottom of the centrifuge through a ground delivery pipeline 3 through a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com