Multi-channel oil-water conveying device and method of arm centrifuge

A technology for conveying devices and centrifuges, applied in centrifuges, centrifuges with rotating drums, etc., can solve problems such as seal failure, no tensile strength, fracture, etc., and achieve the goal of increasing safety and improving safety Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The specific embodiments of the present invention will be further described in detail below with reference to the accompanying drawings.

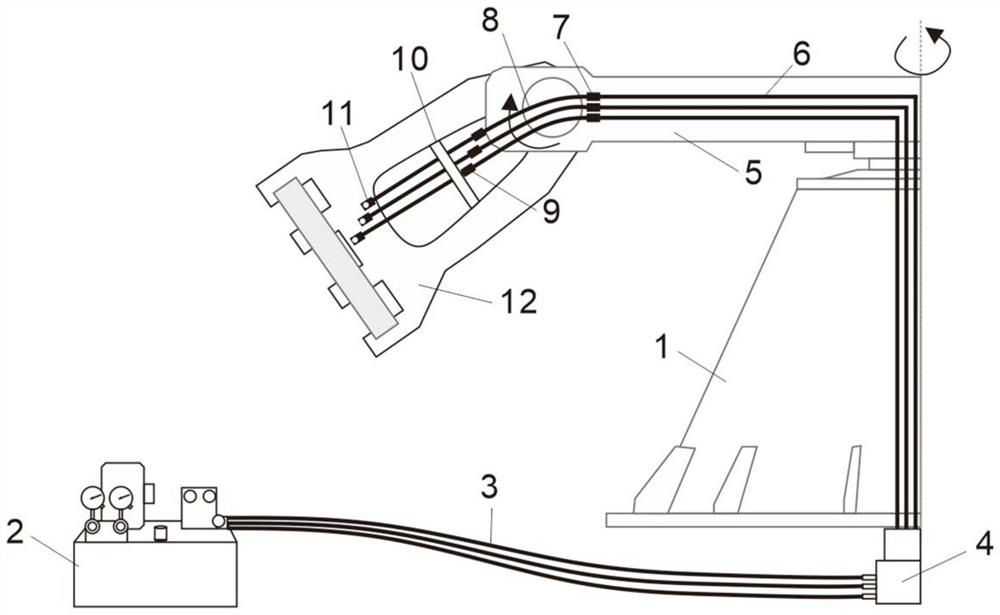

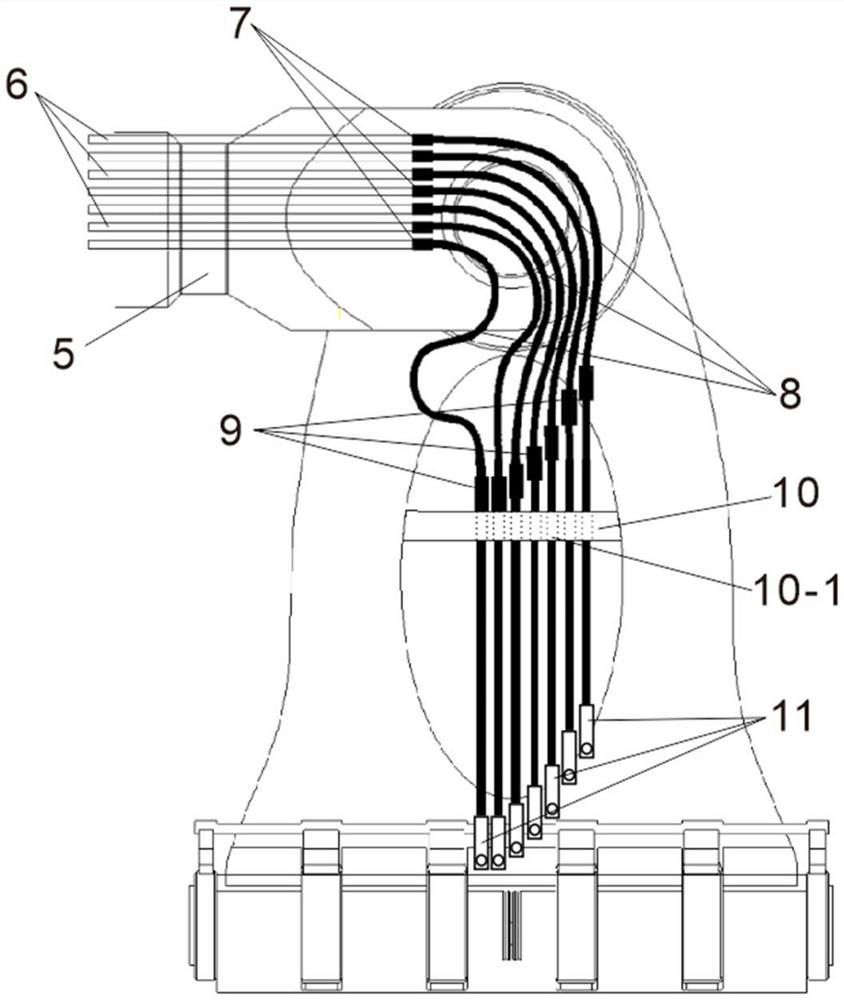

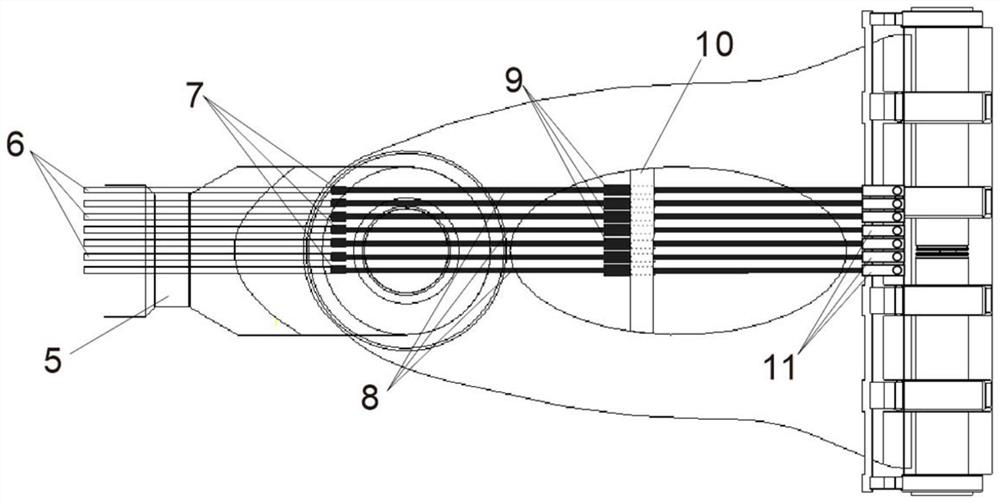

[0032] like figure 1 As shown, the present invention provides a multi-channel oil-water conveying device and method for an arm-type centrifuge, which can satisfy the safe transportation of multi-channel oil, water and gas medium in the centrifuge basket under the condition of high centrifugal force. Including centrifuge host 1, ground liquid source 2, centrifuge bottom rotary joint 4, centrifuge rotating arm 5, rotating arm conveying rigid pipe 6, rotating arm rigid pipe joint 7, basket conveying hose 8, relay reinforcement joint 9. Reinforce the crosspiece 10, the gondola is bent at a right angle to the outlet 11, and the gondola.

[0033] The ground liquid source 2 includes a hydraulic source, a water source, etc., and is connected with the stator end of the rotary joint 4 at the bottom of the centrifuge through a ground conveying...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com