Tire laser speckle defect identification method based on improved residual network

A laser speckle and defect recognition technology, applied in the field of defect recognition based on deep learning, can solve the problems of low recognition accuracy and low missed judgment rate, and achieve the effect of improving safety, reducing pressure and avoiding inefficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] In order to describe the present invention more specifically, the present invention will be described in detail below with reference to the accompanying drawings and specific embodiments.

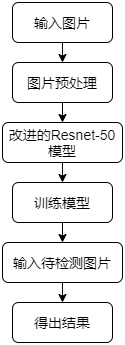

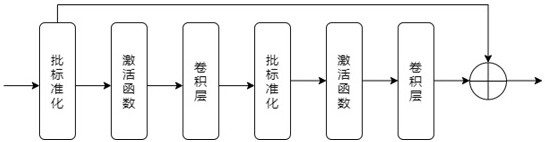

[0025] This example aims to realize defect identification of tire laser speckle images according to the present invention. The method process includes image preprocessing, image enhancement, improving Resnet-50 model training, inputting the image to be tested into the model, and obtaining results. figure 1 The specific implementation process is as follows:

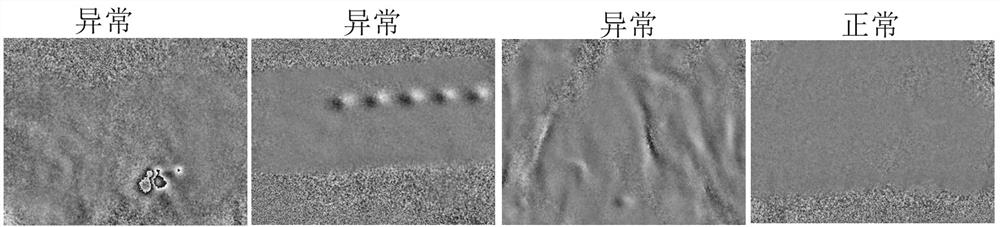

[0026] (1) Pass the tire through the tire laser speckle detector to obtain the original tire laser speckle image.

[0027] (2) Image preprocessing. A tire can be divided into 16 original pictures with a size of 1360*1024 after the tire laser speckle detector, and the original pictures are converted into the format and format size of the input model: 224*224, and the defects and normal xml files are recorded. The preprocessed i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com