Bar code printing quality rating and classified delivery device for printed matter quality inspection

A technology of printing quality and barcode quality, applied in the general parts of printing machinery, printing, printing machines, etc., can solve the problems of slow recognition rate of cigarette label barcode, acceptance dispute of cigarette label barcode printing quality, inconsistent accuracy, etc., to maintain the speed Advantages, solve the problem of rate matching, and meet the effect of automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

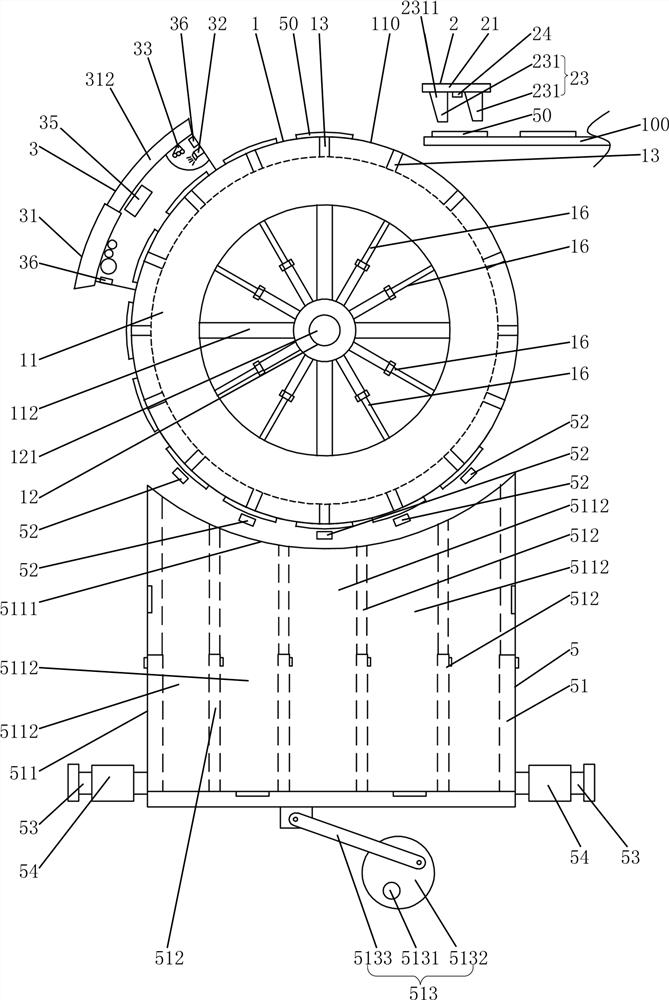

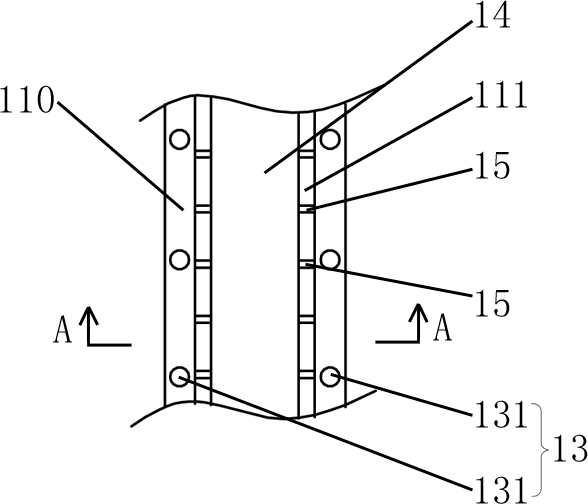

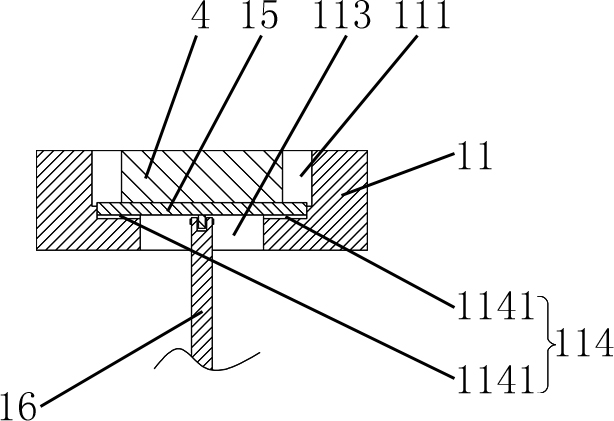

[0032] like Figure 1-Figure 5 As shown in the figure, the barcode printing quality rating and classification delivery device used for the inspection of printed products includes a frame (not shown in the figure), a printed product conveying mechanism 1, a deceleration transfer device 2, a printed product barcode spectrum acquisition mechanism 3, and a printed product barcode. The quality grading mechanism 4, the printed matter sorting, delivery and recycling mechanism 5 and the control device 6; the printed matter conveying mechanism 1 includes a conveying disc 11, a disc drive device 12 for driving the conveying disc 11 to rotate around its axis, and a plurality of material receiving adsorption Component 13, the disc drive device 12 is installed on the frame, the axis of the conveying disc 11 is arranged in the horizontal direction, and each material receiving and adsorbing assembly 13 is arranged on the outer peripheral surface 110 of the conveying disc 11 and along the conv...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com