Ball valve capable of improving sealing performance

A kind of sealing performance, ball valve technology, applied in the valve details, valve device, valve shell structure and other directions, can solve the problem of poor sealing between the ball valve and the pipe network, to enhance the installation stability and compression effect, improve the overall installation sealing, avoid The effect of deformation damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

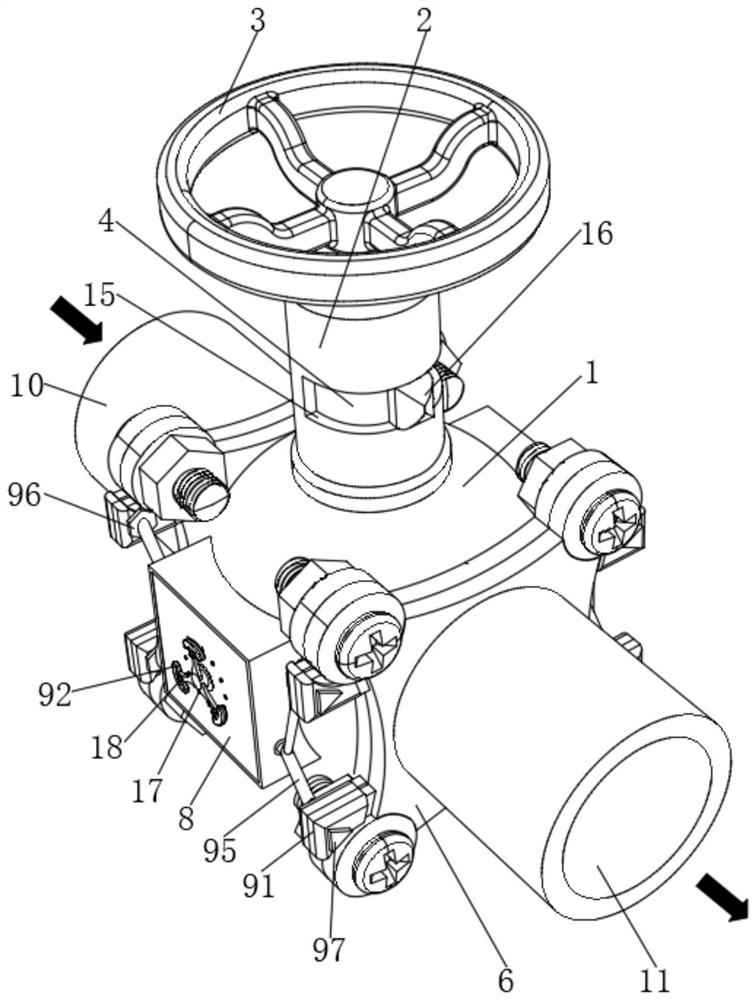

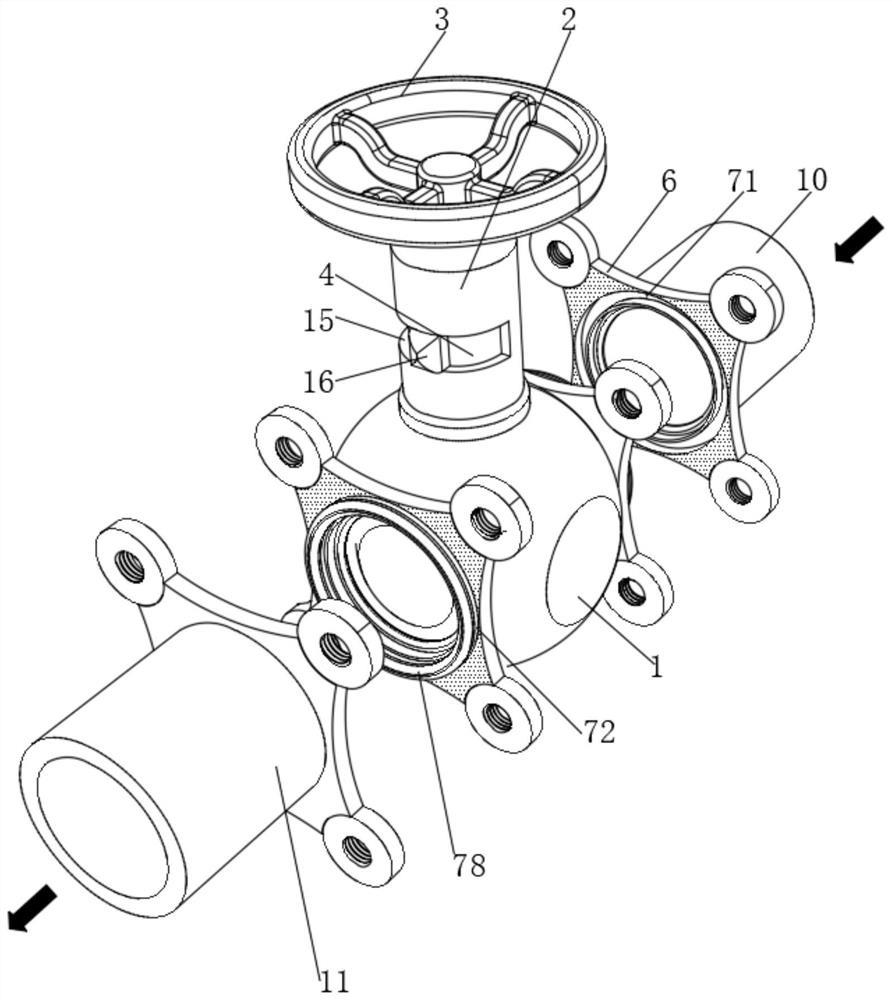

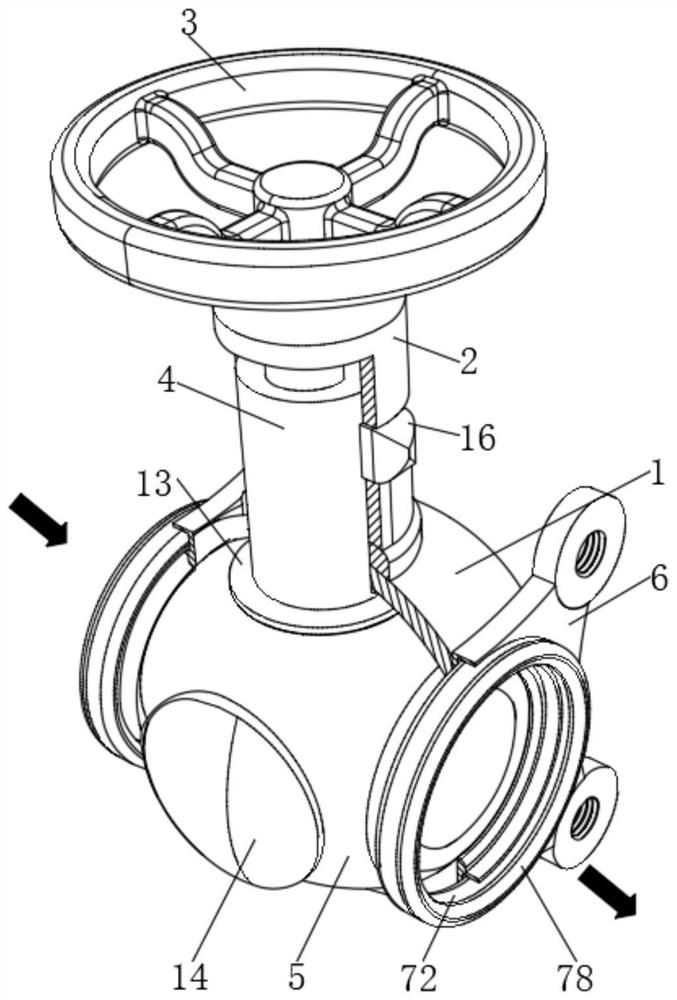

[0029] see Figure 1-6 , the present invention provides a technical solution: a ball valve that can improve sealing performance, comprising a valve body 1, a valve cover 2 is fixedly connected to the top of the valve body 1, a handwheel 3 is rotatably connected to the top of the valve cover 2, and the handwheel 3 The bottom of the valve is provided with a valve stem 4 used in conjunction with the valve cover 2, and the bottom of the valve stem 4 is fixedly connected with a spherical valve core 5 used in conjunction with the valve body 1;

[0030]Both sides of the valve body 1 are fixedly connected with mounting flanges 6 by bolts, and the inner cavity of the two sets of mounting flanges 6 is provided with a sealing structure 7. By setting the sealing structure 7, the annular sealing groove 71, the main sealing ring The cooperation of 72 and the auxiliary sealing ring 78 can realize the sealing function of the secondary seal inside the two sets of installation flanges 6, and im...

Embodiment 2

[0032] see Figure 1-6 , the present invention provides a technical solution: a ball valve that can improve sealing performance, comprising a valve body 1, a valve cover 2 is fixedly connected to the top of the valve body 1, a handwheel 3 is rotatably connected to the top of the valve cover 2, and the handwheel 3 The bottom of the valve stem 4 is provided with a valve stem 4 used in conjunction with the valve cover 2, an arc-shaped through groove 15 is opened in the center of the right side of the valve cover 2, and the top of the right side of the valve stem 4 is fixedly connected with the arc-shaped through groove 15. The limit bump 16 can limit the rotation angle of the valve stem 4 to prevent the construction personnel from mishandling the valve stem 4, and also effectively protect the spherical valve core 5. The limit bump 16 is located in the arc-shaped through groove 15. The maximum rotation angle inside the valve is not more than 180°, the bottom of the valve stem 4 is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com