Bumping walking fatigue testing machine for leather suitcase

A fatigue testing machine and luggage technology, which is applied in the testing of mechanical parts, the testing of machine/structural parts, instruments, etc., can solve the problems of waste of resources, inability to adjust the clamping tools, and scrapped luggage, etc., and improve the fixation. , Increase the effect of fixing and improving the transmission effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

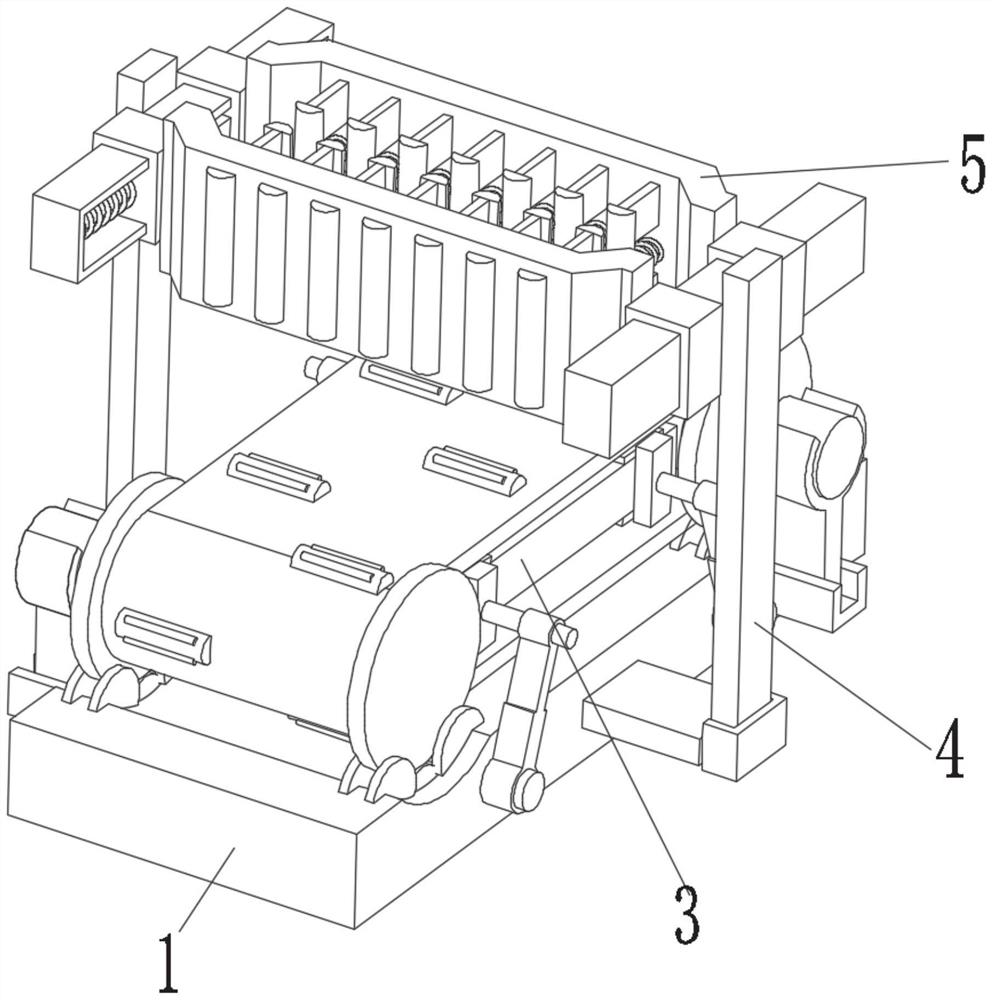

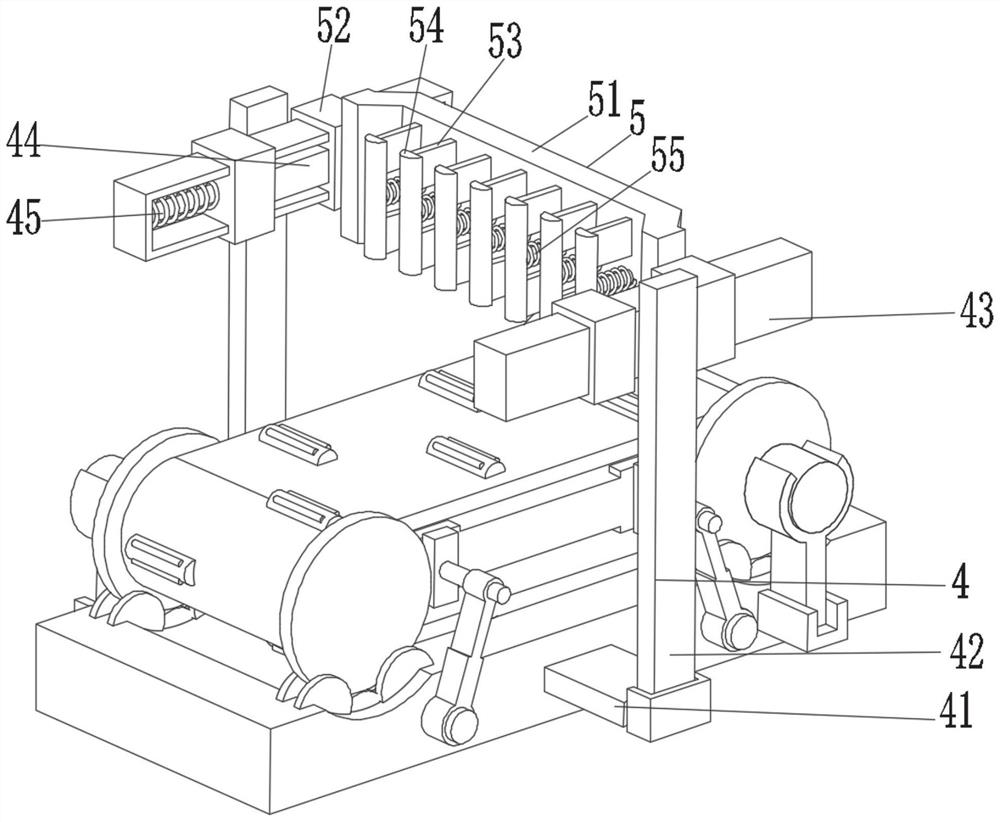

[0024] see Figure 1-Figure 3 , the present invention is a luggage bumpy walking fatigue test machine, comprising a bottom block 1, a transmission assembly 2, a support assembly 3, a fixing assembly 4 and a clamping assembly 5, the transmission assembly 2 is arranged directly above the bottom block 1, and the The supporting assembly 3 is arranged inside the transmission assembly 2, the fixing assembly 4 is arranged on the left and right sides of the bottom block 1, and the clamping assembly 5 is arranged directly above the transmission assembly 2;

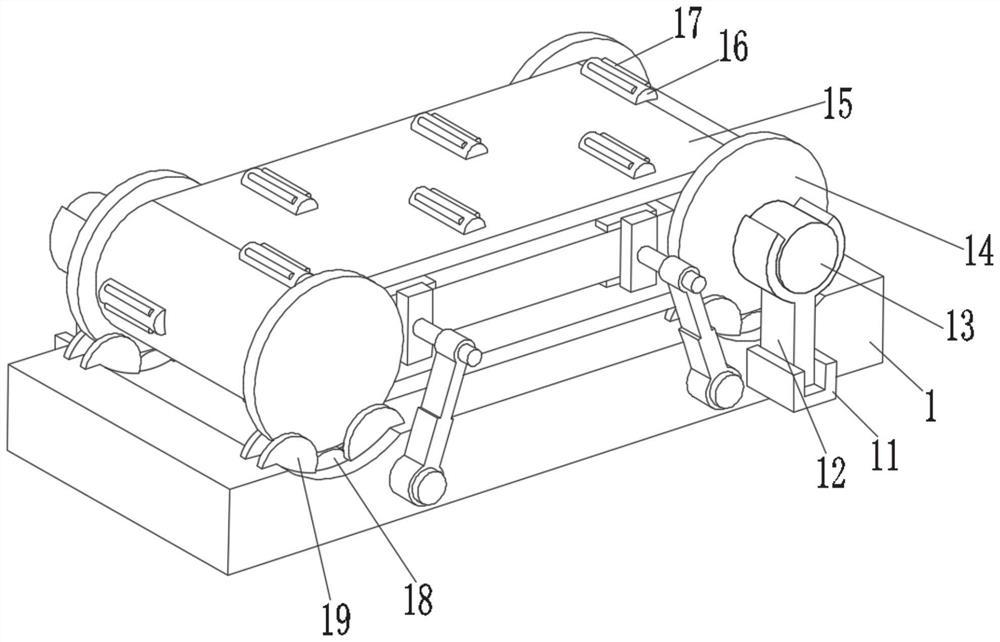

[0025] The bottom block 1 includes a concave block 11, a pole 12, a protection block 13, a circular plate 14, a transmission belt 15, a semi-arc block 16, a small arc block 17, a runner 18 and a positioning plate 19, and the concave block 11 Fixedly connected to the left and right sides of the bottom block 1, the support rod 12 is fixedly installed on the inner surface of the concave block 11, the top shape of the support rod 12 is...

Embodiment 2

[0034] see Figure 1-Figure 5 , the present invention is a luggage bumpy walking fatigue test machine, comprising a bottom block 1, a transmission assembly 2, a support assembly 3, a fixing assembly 4 and a clamping assembly 5, the transmission assembly 2 is arranged directly above the bottom block 1, and the The supporting assembly 3 is arranged inside the transmission assembly 2, the fixing assembly 4 is arranged on the left and right sides of the bottom block 1, and the clamping assembly 5 is arranged directly above the transmission assembly 2;

[0035] The bottom block 1 includes a concave block 11, a pole 12, a protection block 13, a circular plate 14, a transmission belt 15, a semi-arc block 16, a small arc block 17, a runner 18 and a positioning plate 19, and the concave block 11 Fixedly connected to the left and right sides of the bottom block 1, the support rod 12 is fixedly installed on the inner surface of the concave block 11, the top shape of the support rod 12 is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com