Drag hook bar modeling tool for complex steel bar engineering

A technology of reinforcement engineering and hook reinforcement, which is applied in the field of modeling tools for tension reinforcement in complex reinforcement engineering, and achieves the effect of fine and efficient modeling.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

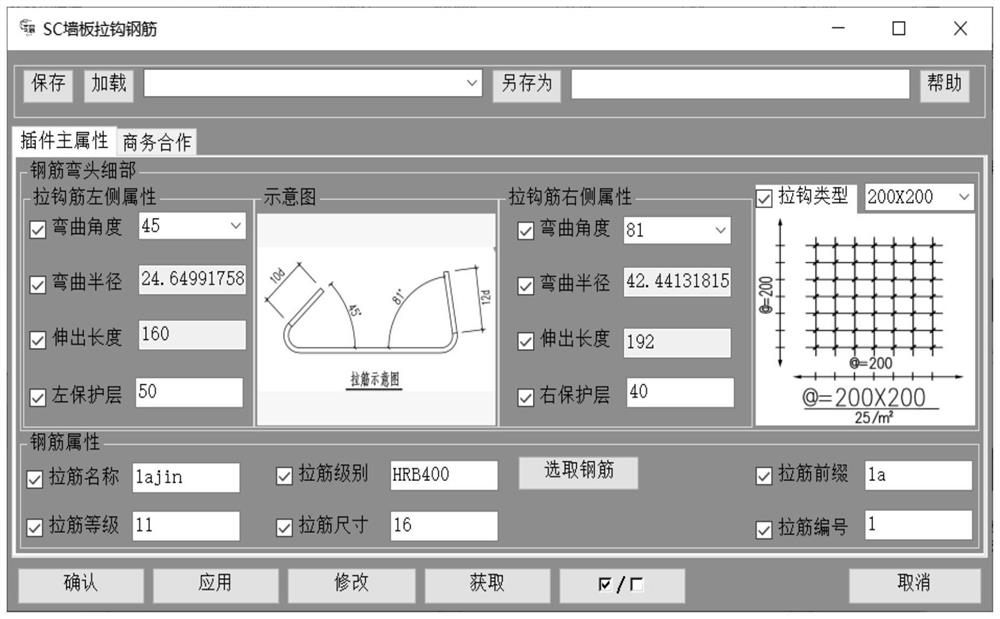

[0022] A modeling tool for drawing hook bars for complex reinforcement engineering. The modeling tool relies on C# development, including a winform interface that can edit and modify data parameters at the front end, which is used for users to adjust the data information of steel bar drawings visible to the human eye. Further, the front-end data parameters The interface includes the important data parameter interface of the steel bar; the back-end design of various functions and method bodies runs as a class library, which is used to accept the parameters input from the front-end data interface, and pass the parameters into the function bodies of various modeling methods, so as to modify the model intelligently at the bottom layer. ;

[0023] Attributes of the front-end tie bars of the modeling tool: The tie bar types include the three types of 200*200, 200*400, and 400*400 specified in the technical specification. Bending angle, radius, length, fit the protective layer of the...

Embodiment 2

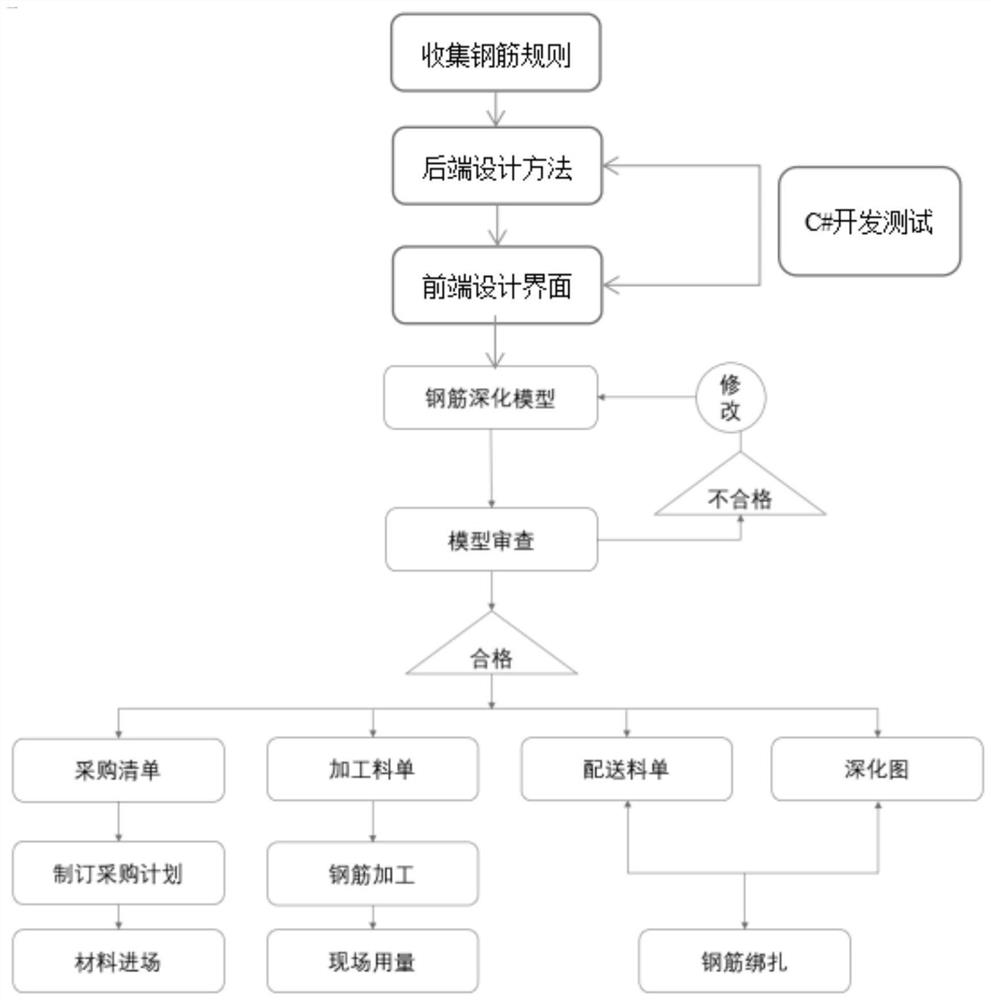

[0026] Modeling tool design and implementation process

[0027] 1. Gather the steel bar rules for wall panel hooks;

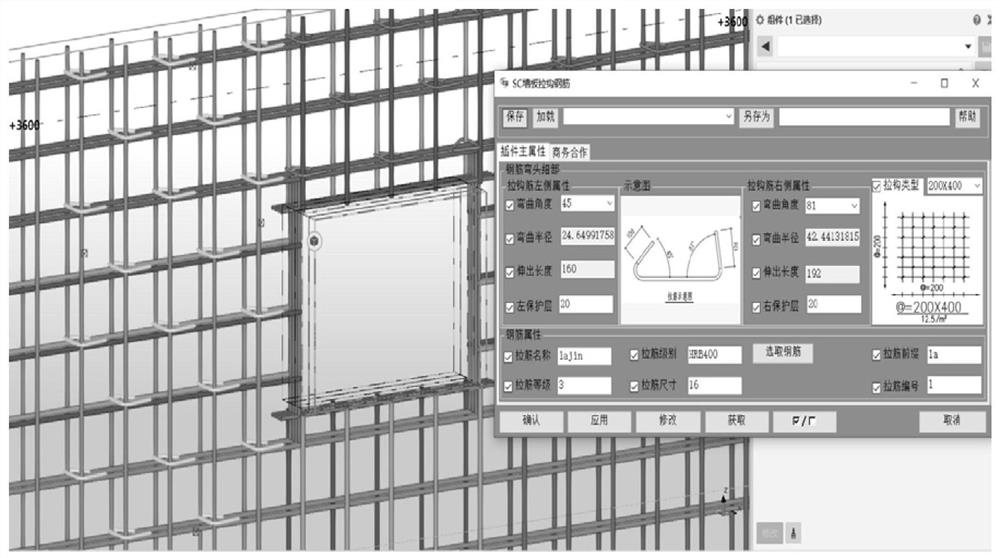

[0028] 2. Begin to use C# to develop tie-bar modeling tools. During the front-end and back-end interactive tests, the rules of wallboard tie-bars are skillfully integrated into the wallboard tie-bar modeling tool. Due to the difficulty of modeling wallboard tie-bars in Tekla software , and even only draw hook bars one at a time, and in complex projects, wall panel hook bars are arranged by area, not by wall, so this modeling tool makes up for the hook bars in Tekla reinforcement modeling. The function of the module makes the modeling more refined and efficient. figure 1 The actual modeling effect diagram for the modeling tool, and the parameter interface in the actual application of the modeling tool. figure 2 The front-end user visual interface after the development of the modeling tool is completed;

[0029] 3. After completing the development of the mode...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com