Device and method for preventing deflection of steel backing in pressing process of composition brake shoe

A technology for synthesizing brake shoes and pressing process, which is applied to household appliances, other household appliances, household components, etc., can solve the problem of steel back offset during the pressing process of brake shoes, and achieve the effect of preventing steel back deflection and eliminating appearance defects.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

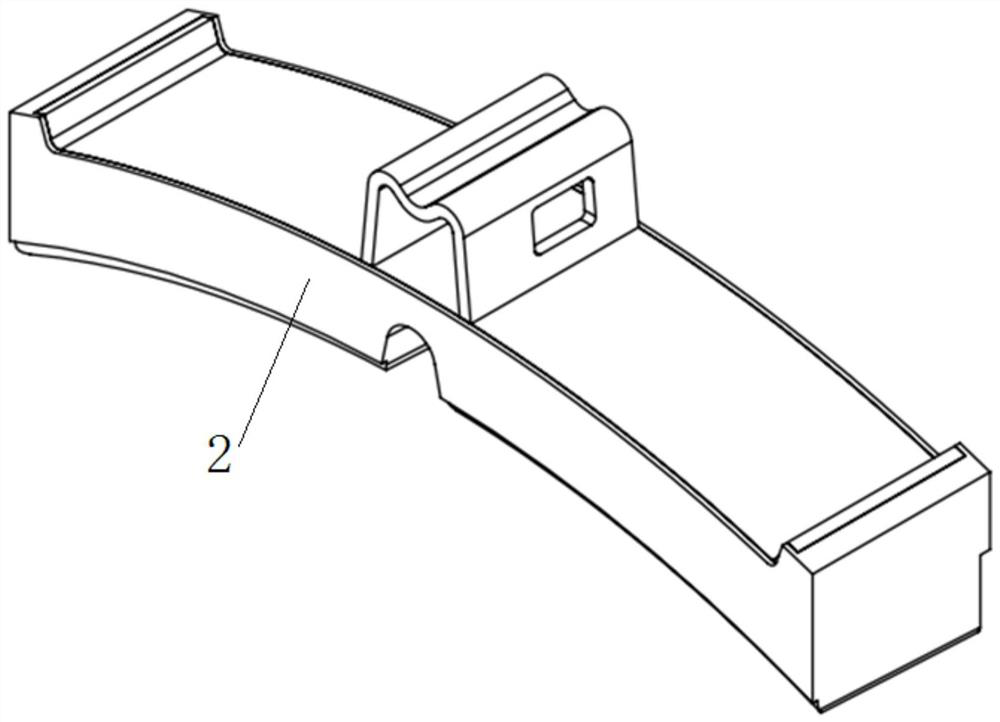

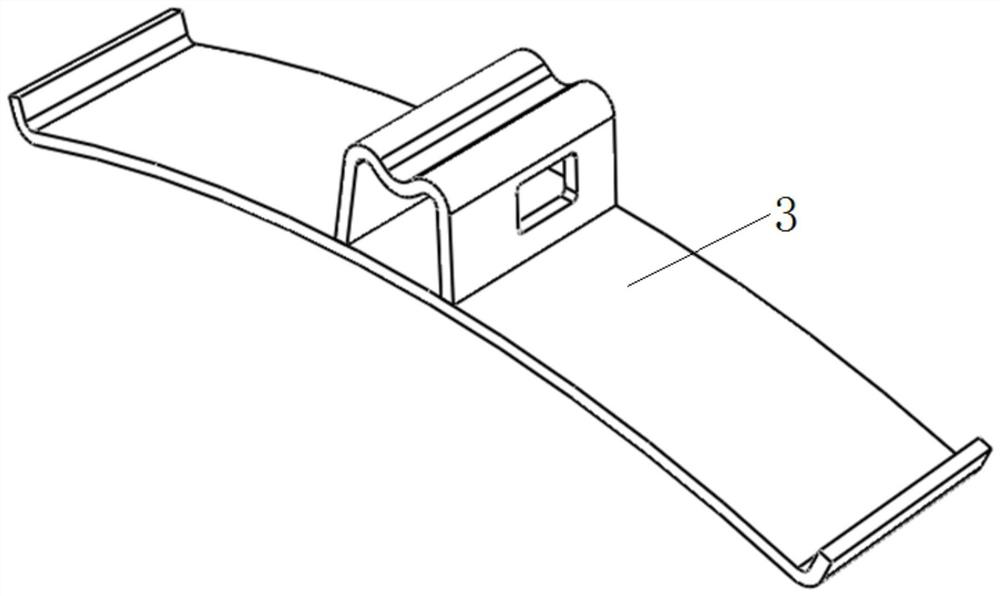

[0029] A device for preventing the deflection of the steel back during the pressing of a synthetic brake shoe, such as Figure 1 to Figure 6 As shown, it includes an anti-rotation baffle 1, a synthetic brake shoe 2, a steel back 3, a lower pressure head 4 and an upper pressure head 5, etc., among which:

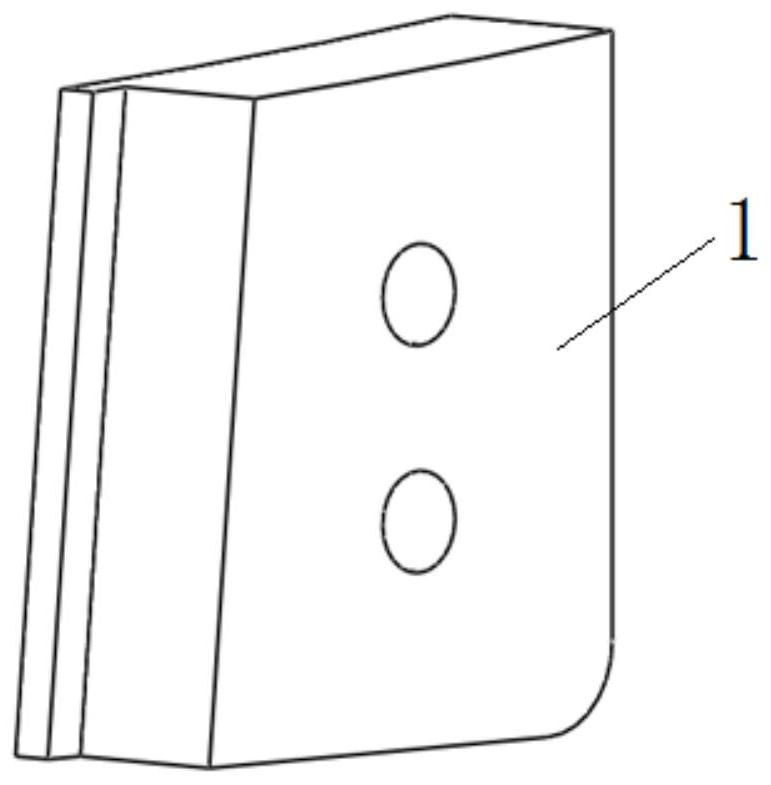

[0030] like figure 1 As shown, the anti-rotation baffle 1 extends 2-3mm from the center of the downward pressure head, the thickness of the extended part is 2 mm, and the upper side of the baffle is consistent with the radian of the downward pressure head.

[0031] like figure 2 and 3 As shown, the width of the steel back 3 is 69mm, and the width of the synthetic brake shoe 2 is 73mm.

[0032] like Figure 4 As shown, the anti-rotation baffle 1 is fixed on the lower pressing head 4 by cylindrical head screws, and two anti-rotation baffles 1 are installed in total.

[0033] Since the tread of the synthetic brake shoe 2 has a slope of 1:20, the corresponding surface slope...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com