Electric connector, charging pile and charging system

A technology for electrical connectors and joints, applied in electric vehicle charging technology, charging stations, electric vehicles, etc., can solve problems affecting vehicle charging efficiency, achieve excellent insulation and heat conduction effects, prevent leakage, and improve transmission efficiency.

Pending Publication Date: 2022-06-07

AUTEL NEW ENERGY CO LTD

View PDF0 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

If the heat is not dissipated in time, it will gre

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Login to View More

Login to View More PUM

Login to View More

Login to View More Abstract

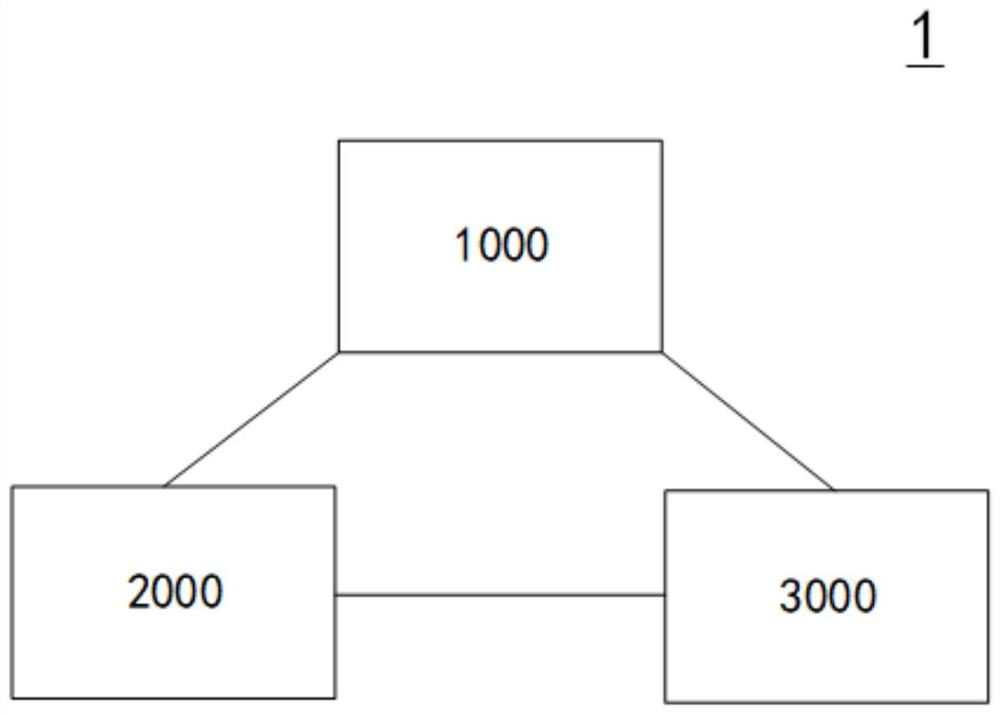

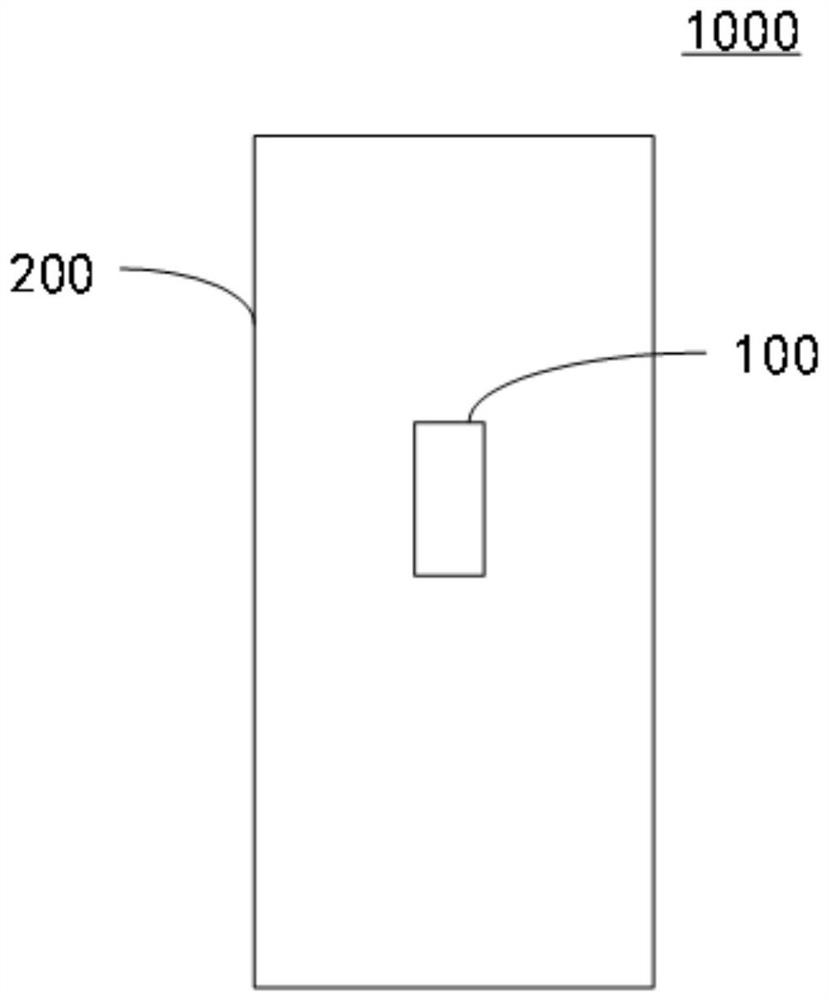

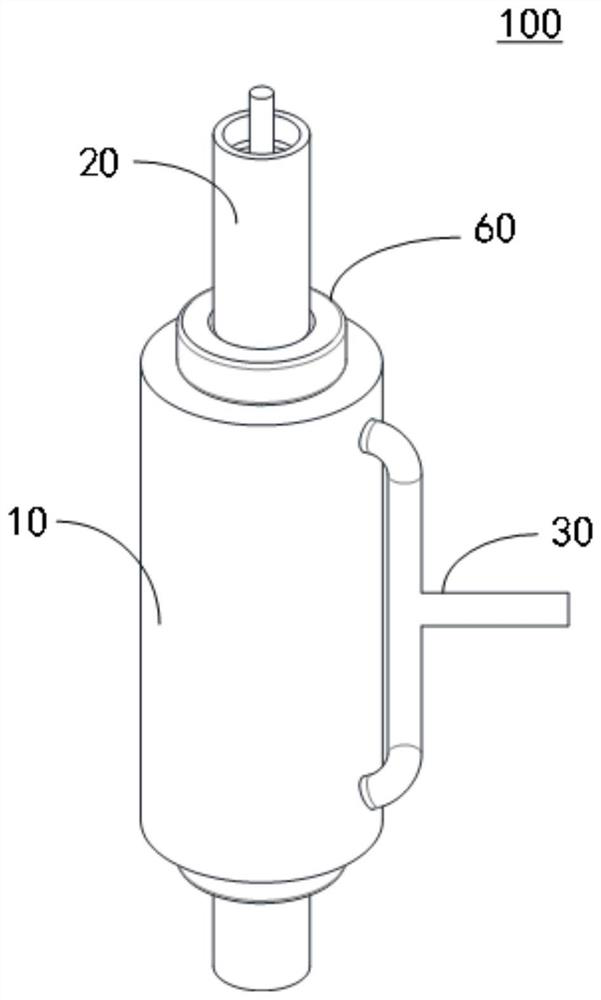

The embodiment of the invention relates to the technical field of electric energy transmission, in particular to an electric connector, a charging pile and a charging system. The electric connector comprises a shell, a joint and a cooling medium, the shell is provided with an accommodating cavity and two oppositely arranged through holes, and the accommodating cavity is communicated with the outside through the through holes. The connector comprises a first part and second parts, the second parts are arranged at the two ends of the first part, the connector is inserted into the shell, the first part is located in the containing cavity, the second parts penetrate out of the through hole and are exposed out of the outer surface of the shell, and the first part is subjected to insulation treatment and heat conduction treatment. The cooling medium is contained in the containing cavity. Through the above structure, after the first part is subjected to surface treatment, excellent insulation and heat conduction effects can be obtained, so that after the joint generates heat, heat is directly dissipated through a cooling medium. Meanwhile, electric leakage of the connector can be effectively prevented after insulation treatment. Therefore, the transmission efficiency of electric energy is improved.

Description

technical field [0001] The embodiments of the present application relate to the technical field of power transmission, and in particular, to an electrical connector, a charging pile, and a charging system. Background technique [0002] New energy vehicles refer to the use of unconventional vehicle fuels as the power source (or the use of conventional vehicle fuels, the use of new vehicle power units), the integration of advanced technologies in vehicle power control and driving, and the formation of advanced technical principles. New technology, new structure of the car. New energy vehicles include four major types of hybrid electric vehicles (HEV), pure electric vehicles (BEV, including solar vehicles), fuel cell electric vehicles (FCEV), and other new energy vehicles (such as supercapacitors, flywheels and other high-efficiency energy storage) vehicles Wait. Unconventional vehicle fuels refer to fuels other than gasoline and diesel. Taking an electric vehicle as an exam...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): B60L53/16B60L53/31B60L53/302

CPCB60L53/16B60L53/31B60L53/302Y02T90/14

Inventor 张铱洪

Owner AUTEL NEW ENERGY CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com