Self-locking bolt assembly for cold-formed thin-walled steel structure anti-pulling piece and installation method of self-locking bolt assembly

A technology for cold-formed thin-walled steel and bolt assemblies, which is used in building structures, buildings, etc., can solve problems such as the inability to meet the firm connection between the overall structure and the foundation, the thin structure of the pull-resistant parts, and the pull-out anchor bolts. To achieve the effect of convenient installation, convenient construction and strong connection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0055] The present invention will be described in detail below with reference to the accompanying drawings and specific embodiments.

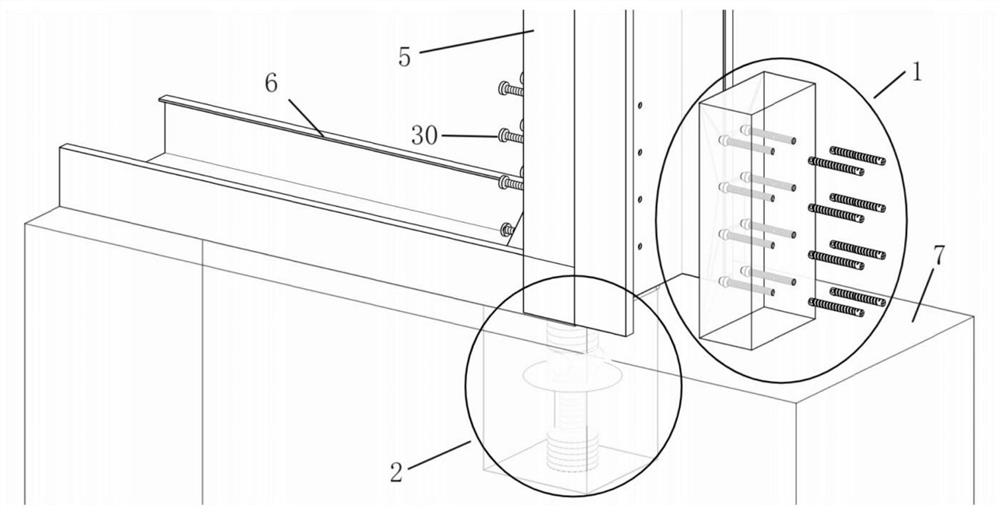

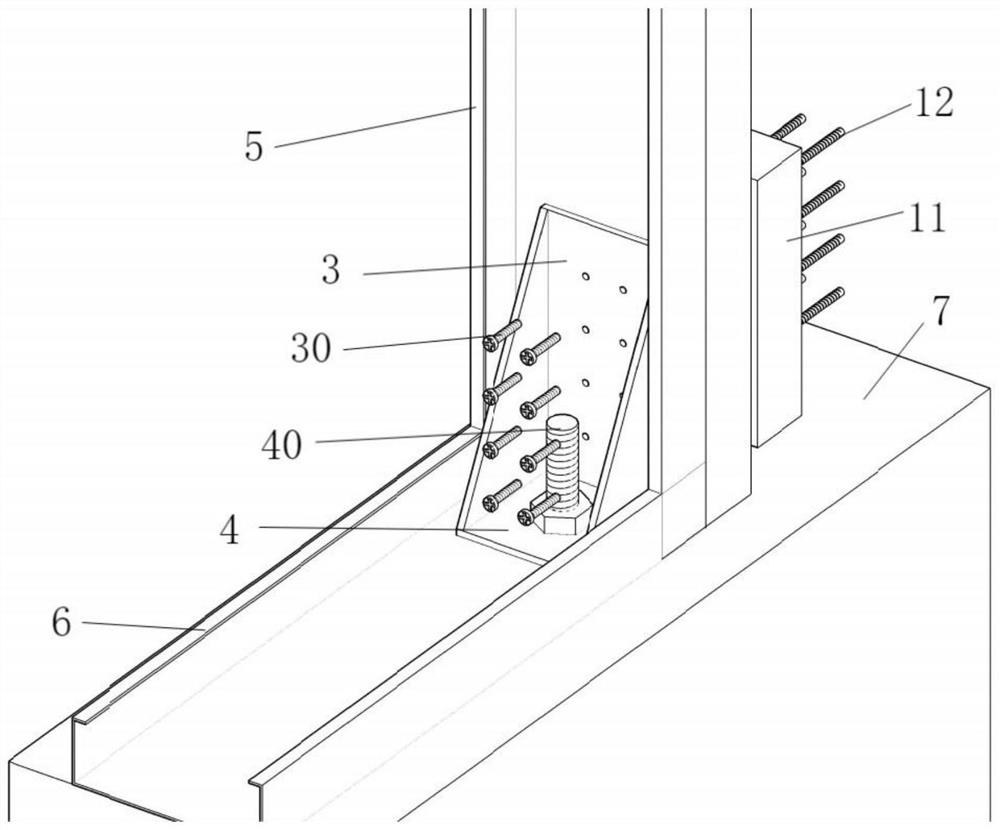

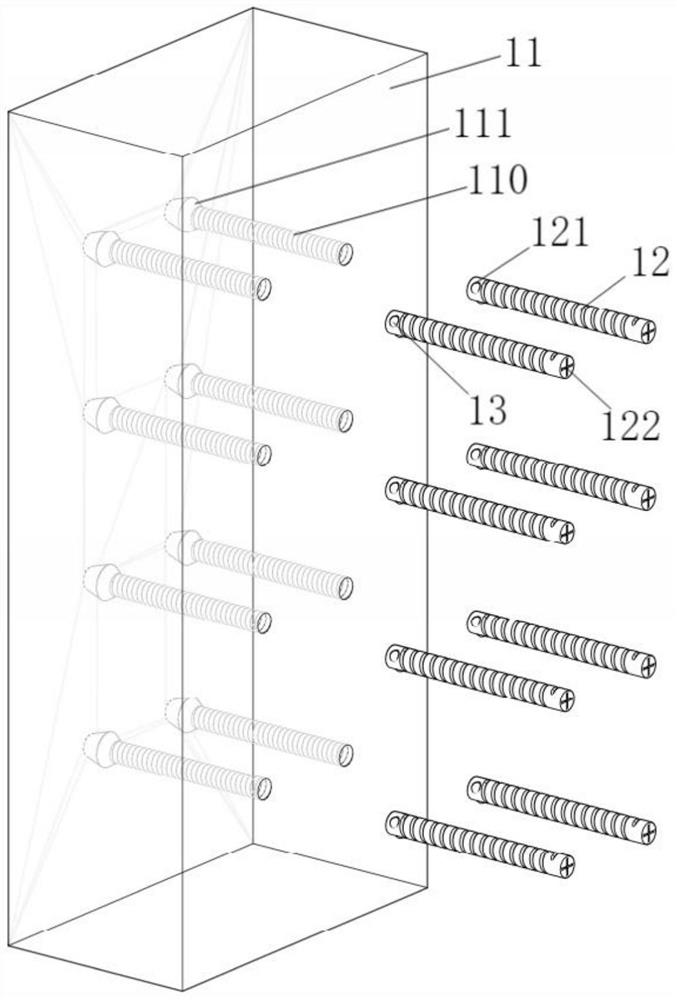

[0056] like Figure 1(a) to Figure 5(c) As shown, the self-locking bolt assembly for cold-formed thin-walled steel structure anti-uplift parts of the present invention includes a first self-locking bolt group 1, and the first self-locking bolt group 1 is arranged on the wall connected with the anti-uplift member web 3 On the body side post 5; the first self-locking bolt group 1 includes a first base 11, a first bolt 12, and a first metal ball 13; the first base 11 is a rectangular iron block, on which a horizontal channel threaded hole 110 is arranged, The end of the horizontal channel threaded hole 110 is provided with a truncated first cavity 111; the first bolt 12 is provided with a first hole 120, and the side of the end of the first bolt 12 is provided with a first circular hole 121, the first circular hole 121 In communication with the f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com