Combined large tent frame

A combined, framed technology, applied in tents/canopies, building types, buildings, etc., can solve the problems of damaged storage bags, heavy weights, scratches on poles, etc., to achieve easy installation and disassembly, improved operability, easy The effect of adjustment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0043] Hereinafter, the technical configuration and embodiments of the present invention will be described in detail with reference to the accompanying drawings prepared on the basis of preferred embodiments of the present invention.

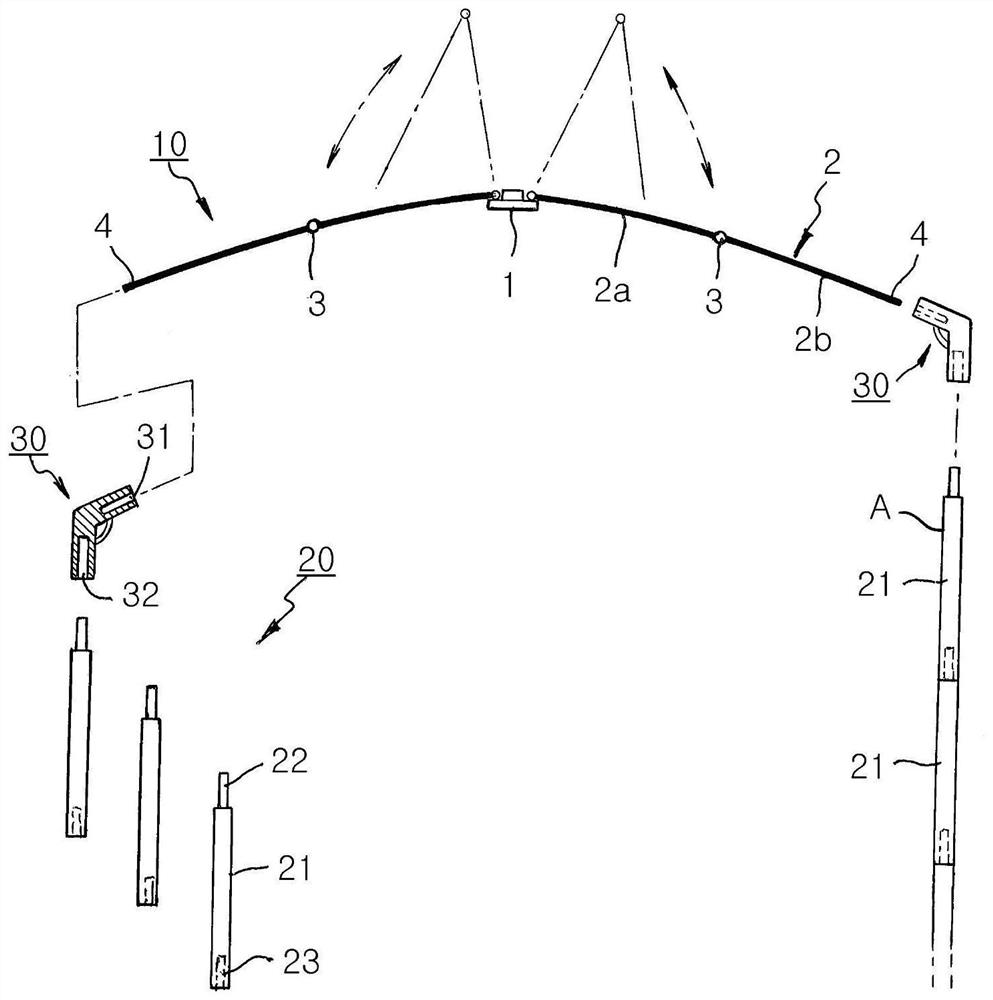

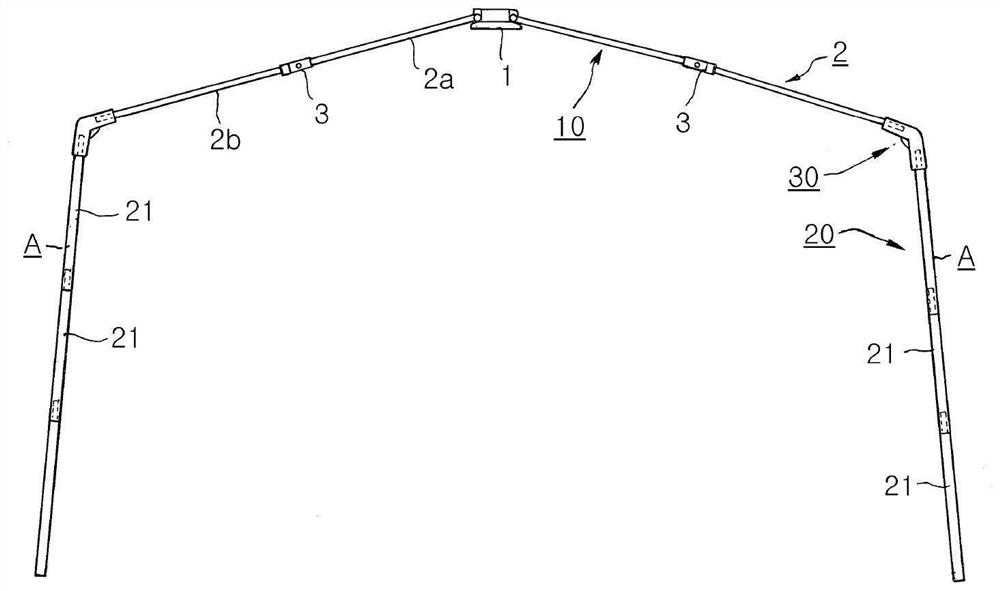

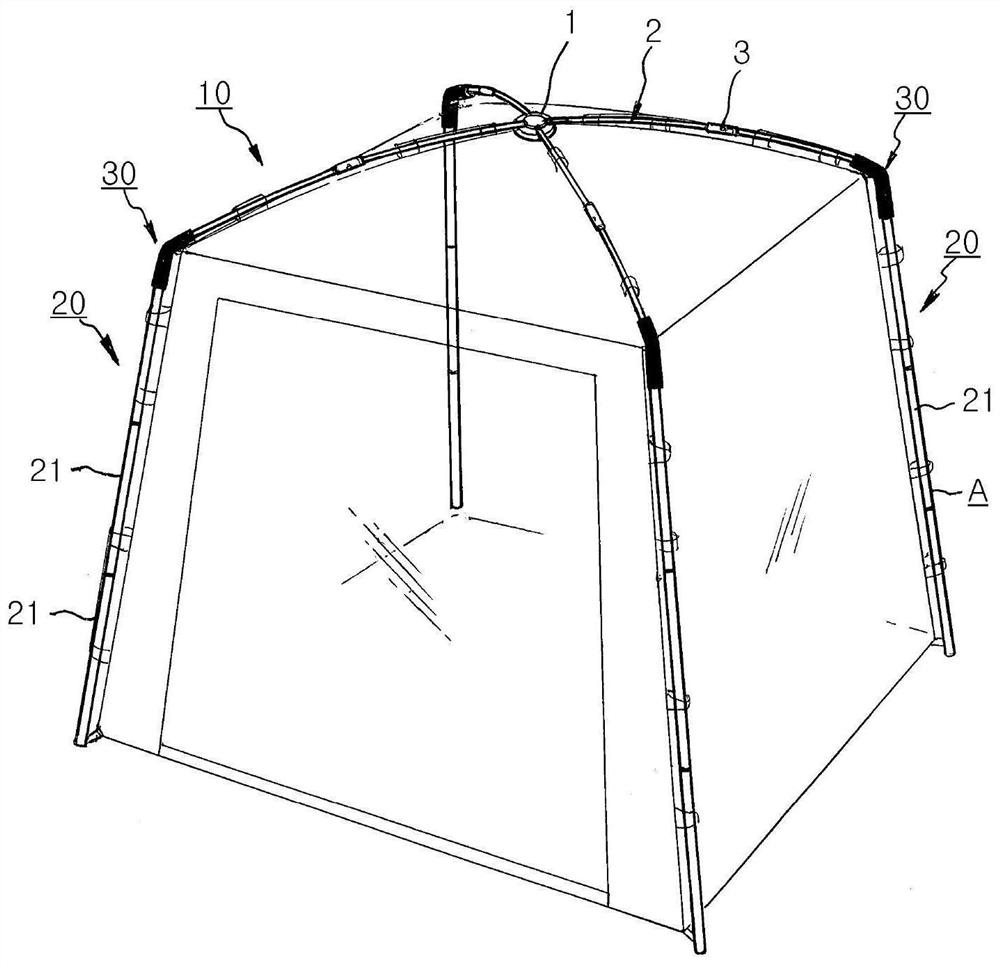

[0044] like figure 1 As shown, in the structure of the large tent frame of the present invention, it is characterized in that the structure of the special combined frame for the large tent includes the following parts combined: an upper frame 10 of an automatic folding structure that forms the top of the tent, and a multi-stage structure that forms the tent. The lower frame 20 of the combined column, and to connect the upper and lower frames 10 and 20 into one body, are combined with the joint 30 between the upper and lower structures.

[0045] The upper frame 10 serves as the top structure of the marquee of the present invention.

[0046] A central head 1 with a circular body is installed in the center of the upper part of the top structure bo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com