Gear transmission piston type compressor

A gear transmission and piston type technology, which is applied in piston pumps, machines/engines, and liquid displacement machinery, can solve the problems of increased piston movement frequency, increased motor power, and reduced piston life, so as to increase air intake The effect of exhaust volume, frequency reduction and stroke increase

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

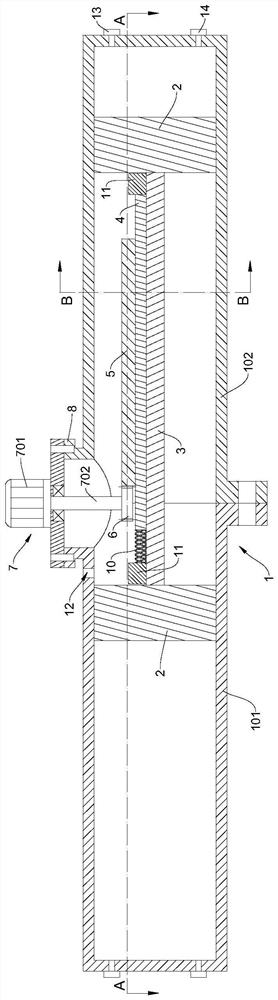

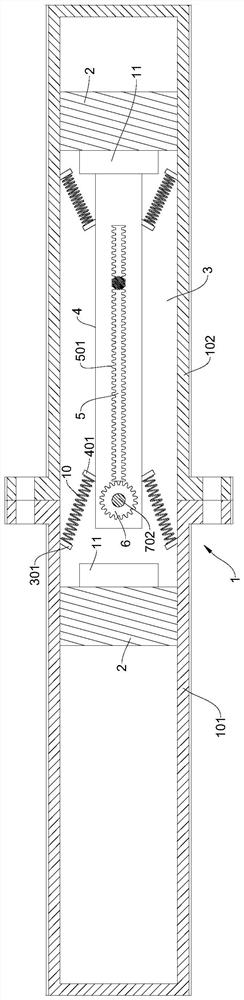

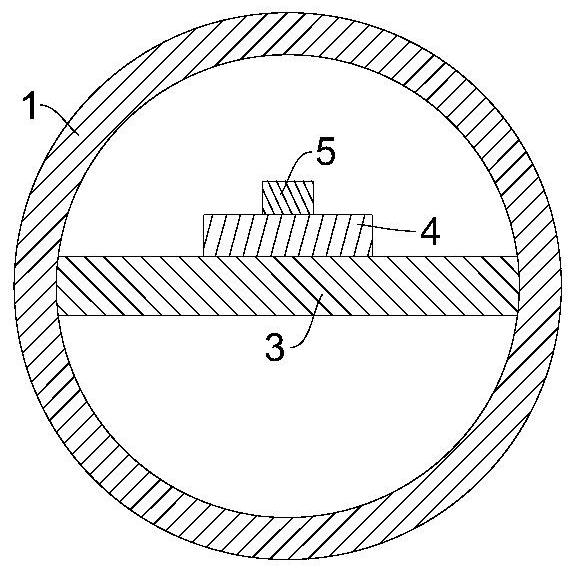

[0020] like Figure 1-4 As shown, a gear-driven piston compressor includes a cylinder block 1, and both ends of the cylinder block 1 are provided with pistons 2 that cooperate with the inner wall of the cylinder block 1, that is, the diameter of the piston 2 is the same as the inner diameter of the cylinder block 1, and it is easy to It is understood that both ends of the cylinder block 1 are provided with an intake valve 13 and an exhaust valve 14 .

[0021] A bottom plate 3 is connected between the two pistons 2, and a thrust plate 4 is placed on the top of the bottom plate 3, that is, the thrust plate 4 can move freely on the bottom plate 3. There is a rack 501, the two racks 501 can be integrally formed, and then welded with the thrust plate 4 or fixed by screws, so that the thrust plate 4 and the gear block 5 can move synchronously. The meshing gear 6, the gear 6 is connected with the driving mechanism 7 that drives it to rotate, the elastic pieces 10 are provided on bot...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com