Safety prevention monitoring system for gas cylinder filling station

A technology for monitoring systems and gas cylinders, applied in container filling methods, equipment loaded into pressure vessels, gas processing/storage purposes, etc., can solve problems such as inability to upload real-time scenes to the background server, and achieve the effect of avoiding accidents

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

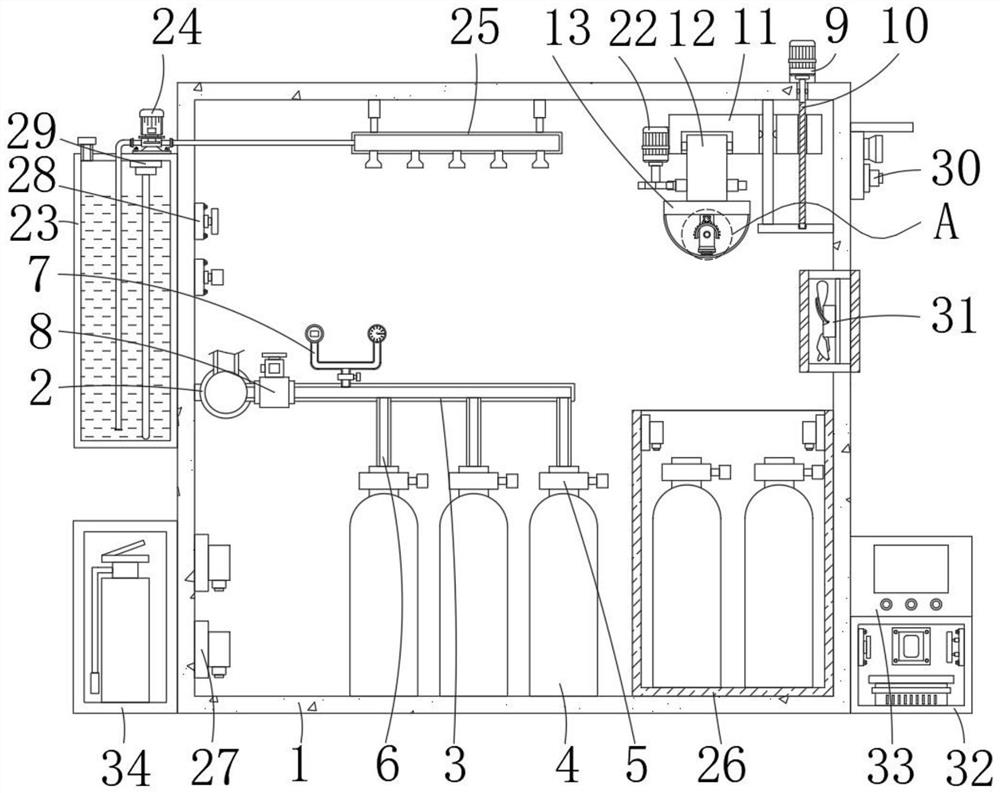

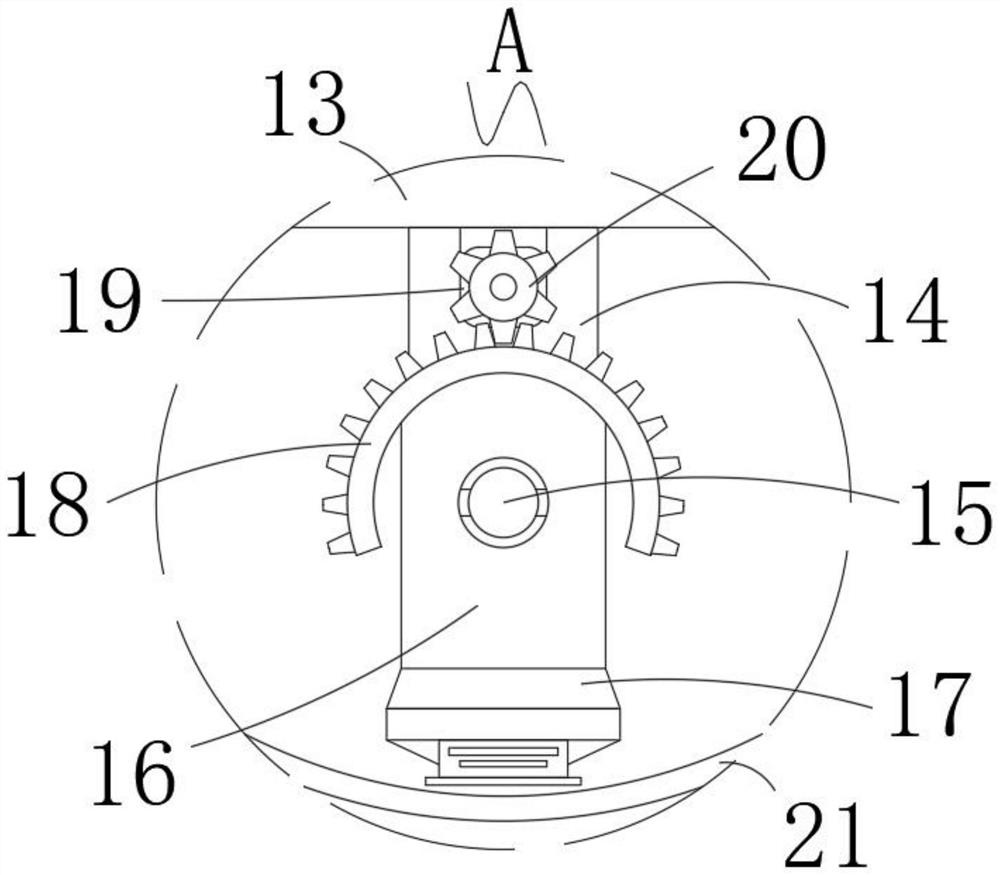

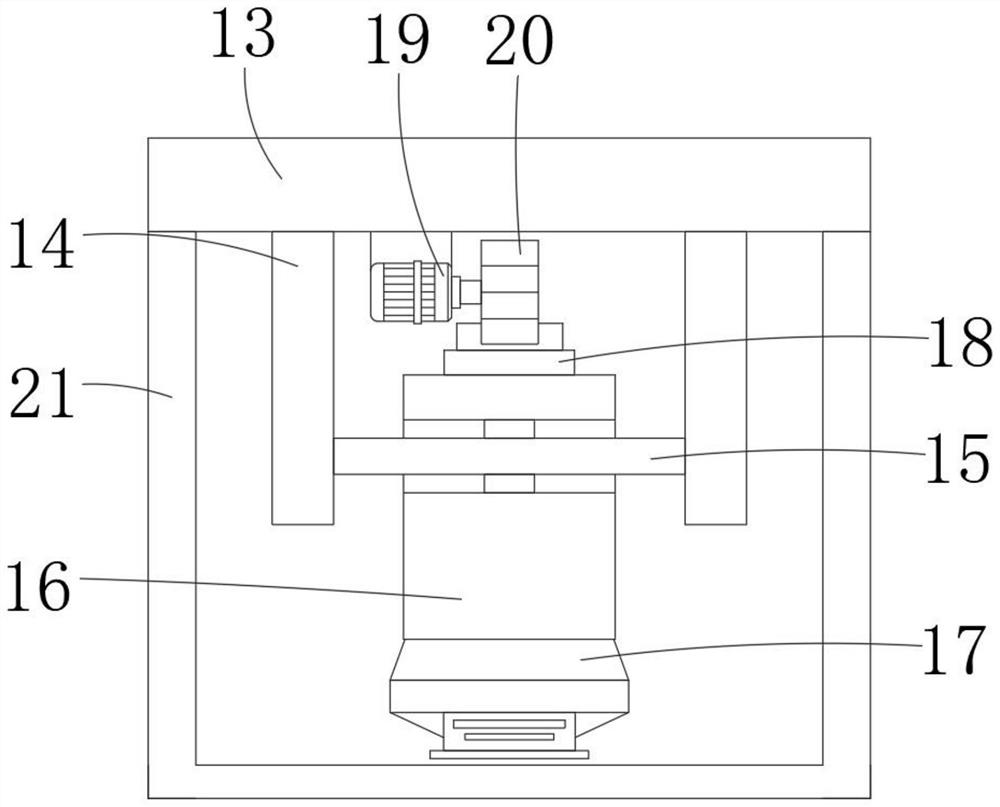

[0027] Please refer to figure 1 , figure 2 , image 3 , Figure 4 and Figure 5 ,in, figure 1 It is a schematic cross-sectional structural schematic diagram of the safety prevention monitoring system of the gas cylinder filling station of the present invention; figure 2 for figure 1 A schematic diagram of the enlarged structure of Part A; image 3 It is the assembly drawing of the installation plate, the support plate, the fixed rod, the rotating plate, the camera, the curved tooth plate, the rotating motor, the first gear and the protective cover in the present invention;

[0028] Figure 4 It is a schematic structural diagram of the front view of the safety prevention monitoring system of the gas cylinder filling station of the present invention; Figure 5 This is the principle block diagram of the safety prevention monitoring system of the gas cylinder filling station of the present invention. The safety prevention monitoring system of the gas cylinder filling st...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com