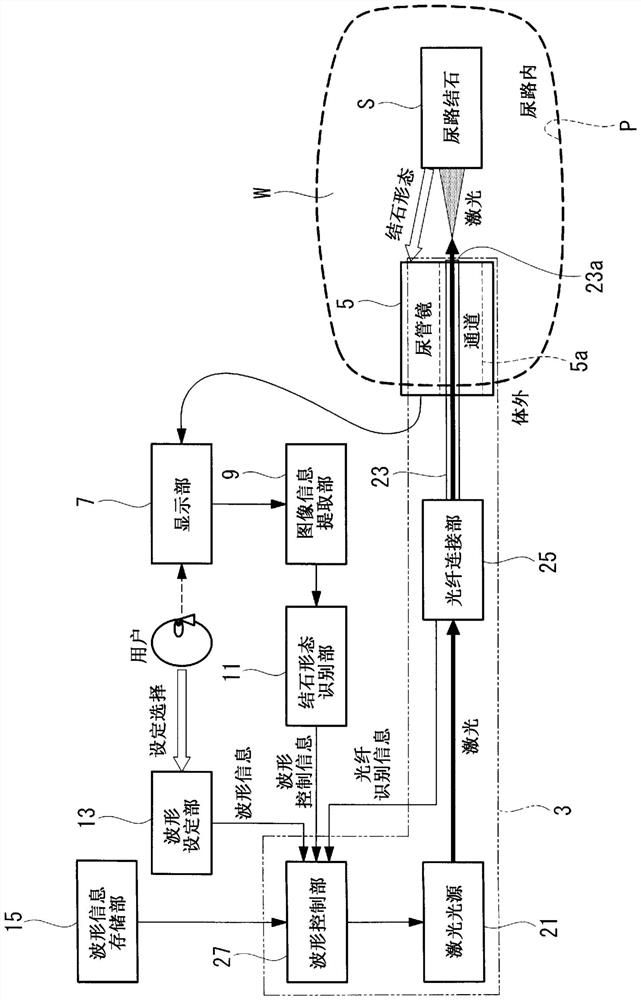

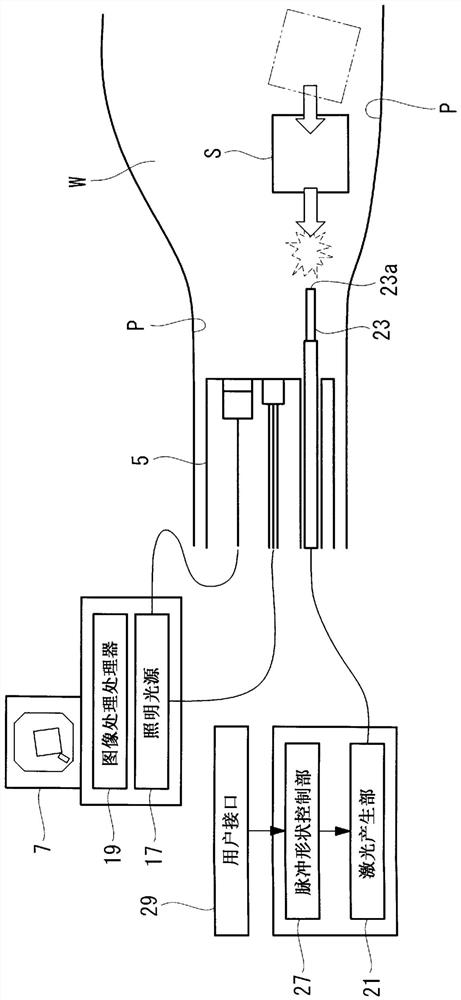

Laser crushing device, laser crushing system and laser crushing method

A technology of laser crushing and laser light source, used in lasers, laser welding equipment, laser parts and other directions, and can solve problems such as the detailed mechanism that has not yet been clarified

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0153] Next, examples of the laser fragmentation device 3 , the laser fragmentation system 1 , and the laser fragmentation method according to the above-described embodiments will be described.

[0154] (method)

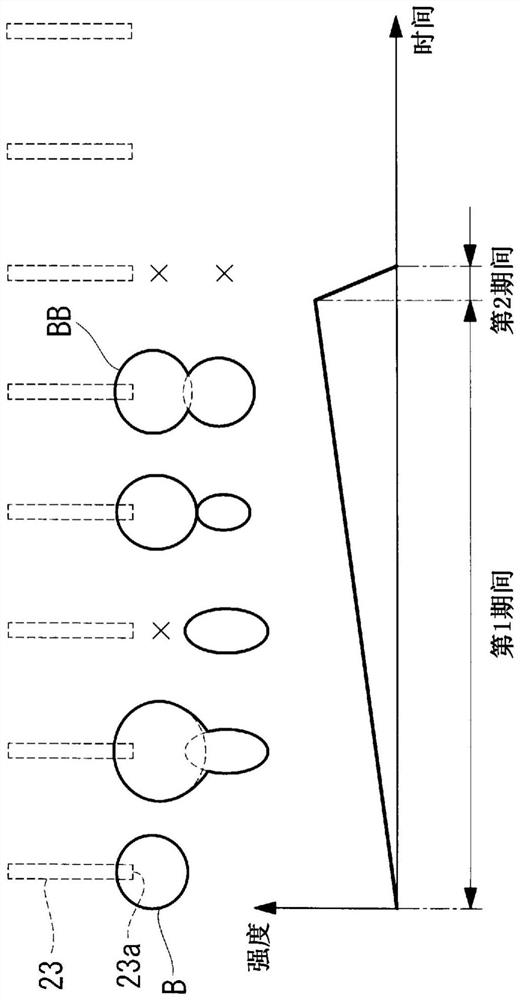

[0155]In this embodiment, four pulse shapes with the same pulse energy, that is, square pulse (Squre: Sq), descending triangle pulse (Descending Triangle: DT), ascending triangle pulse (Ascending Triangle: AT), and M-shaped pulse are used. (M-shaped Pulse: MP) as a comparison object. Optical energy transmission was carried out using a fiber with a core diameter of 270um (HLFDBX0270c, DornierMedTech). Table 1 shows the pulse shape parameters, Figure 10 Indicates the pulse shape of each pulse.

[0156] [Table 1]

[0157] Pulse shape parameters

[0158]

[0159] Furthermore, as Figure 10 The pulse energy (J), average power (W), and pulse width (μs) of parameters other than the shown pulse shape are selected in this embodiment, and can be referred to as exampl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com